Aerodynamics Simulation

Fluids Simulation for Aerodynamics Performance

What is Aerodynamics Simulation?

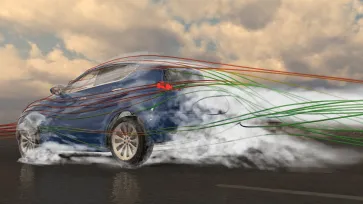

Aerodynamics design starts from the earliest stages of development, but it is affected by both large structures and tiny details that change right through the process. Integrating simulation into design allows engineers to optimize the performance of their product and resolve potential issues without the cost of wind tunnel testing.

Industry Challenges Solved by Aerodynamics Simulation

Aerodynamics is a crucial concern across a wide range of industries. The automotive industry was a pioneer in the field, using the understanding of how air flows around vehicles to reduce drag to produce faster cars with better fuel economy. It is also a self-evident requirement in the aerospace industry, especially as high fuel costs and tightening emissions regulations mean that even the smallest reduction in drag is worthwhile. Even large fixed structures such as buildings and industrial equipment can benefit from aerodynamic design to reduce wind load and improve airflow.

Supplementing wind tunnel testing with simulation reduces costs by replacing physical prototypes with a virtual twin. It also represents a significant time saving, as tests that can take weeks to prepare physically can be replicated in simulation with an overnight turnaround. Allowing designers to analyze aerodynamic performance from the very start reduces the time and cost associated with fixing issues later. Simulation fosters innovation by allowing users to experiment with new concepts that can improve performance and offer a competitive edge.

Aerodynamic Design & Simulation Solutions

The SIMULIA brand of Dassault Systèmes offers a portfolio of powerful fluid simulation tools that can tackle a wide range of aerodynamic scenarios and challenges including:

- Aerodynamic efficiency and drag reduction

- High lift systems and flight dynamics

- Vehicle handling

- Soiling – mud, rain, and snow management

- Panel deformation

- Wind load

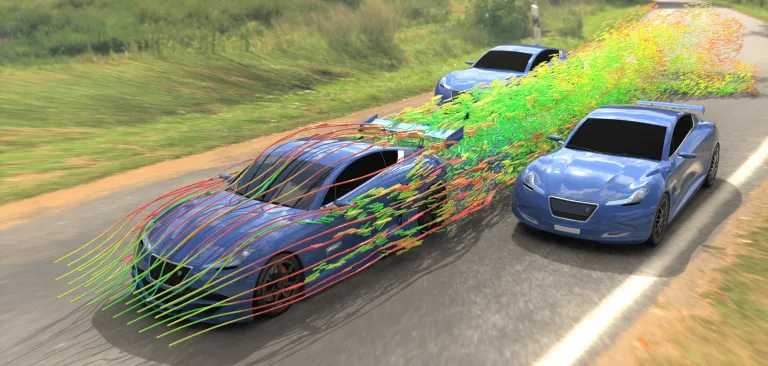

SIMULIA aerodynamics simulation tools use the high-performance Lattice Boltzmann Method CFD simulation technology to accurately simulate the flow of air around large structures, including turbulence. The interaction between air and other fluids such as water and mud can be simulated for analyzing effects such as rain and soiling. Moving parts can be taken into account in the aerodynamic study, as can the road surface, other vehicles, and the environment.

The aerodynamics solutions can also link to other fluids subdisciplines such as aeroacoustics, to structural and motion simulation tools, and to modeling tools for an integrated modeling/simulation (MODSIM) workflow.

- Aerodynamic Efficiency

- High Lift Systems and Flight Dynamics

- Vehicle Handling

- Soiling

Aerodynamic Efficiency

Aerodynamic design has a critical impact on fuel efficiency, by reducing wind resistance and optimizing the airflow through the engine. Simulation offers insight into aircraft and vehicle aerodynamics and can reveal real-world issues that aren’t seen in the wind tunnel. Simulation provides cost savings and improvement in the final design.

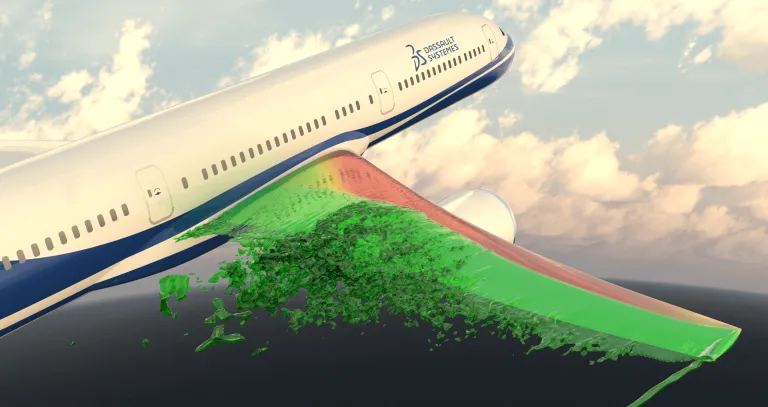

High Lift Systems and Flight Dynamics

Many trade-offs must be considered when designing a wing or rotor, including performance, maximum lift, weight, cost, and noise. Simulation can optimize high-lift surface design, providing results overnight that could once have taken months of wind tunnel testing. Simulation can take into account all relevant flow regimes at different Mach numbers.

Vehicle Handling

Forces such as drag, lift, downforce and crosswind affect the grip that the tires have on the road, response of the vehicle to steering inputs, and stability of the vehicle to changes in the road or wind conditions. Understanding these results can improve vehicle safety and passenger comfort and provide the competitive edge for race cars.

Soiling

Water, snow, ice, dirt, rocks, and other particles of debris can be kicked up off the road by tires or wind, or are present due to weather conditions. The small size of these particles dictates that they are strongly influenced by vehicle aerodynamics, and careful design can reduce the soiling and damage they cause.

Start Your Journey

Explore the technological advancements, innovative methodologies, and evolving industry demands that are reshaping the world of Aerodynamics Simulation. Stay a step ahead with SIMULIA. Discover now.

FAQs about Aerodynamics Simulation

CFD simulation reveals the aerodynamic behavior of an object such as a car or aircraft without having to test a physical prototype in a wind tunnel. Airflow can be visualized in 3D and KPIs calculated instantly. The effect of design changes can be easily calculated, accelerating the development process and helping to optimize designs to minimize drag.

In the SIMULIA portfolio, PowerFLOW is the most suitable solution for most aerodynamic flow simulations of vehicles and aircraft. PowerFLOW uses the Lattice Boltzmann Method (LBM) for CFD simulation to calculate airflow around objects in many different flow regimes and Mach numbers, from subsonic to supersonic.

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering