Verity™ Module in fe-safe

Durability Analysis Software for Finite Element Models

Simplified Fatigue Life Prediction

The calculation of fatigue lives has traditionally been a notoriously complex and difficult task. The prediction of fatigue life and failure locations for welded joints and welded structures, including spot welds, can often result in poor correlation with test data. The Verity Structural Stress Method was developed and patented by Battelle. It was a major breakthrough in the fatigue analysis of welded joints from finite element models.

Verity in fe-safe combines Verity for the fatigue of welded structures with the advanced features of fe-safe for fatigue analysis for finite element models. It allows companies to reduce or avoid the expense of testing to validate the integrity of designs and avoid the common practice of over-engineering due to the uncertainty of fatigue life.

- At a Glance

- Capabilities

- Benefits

Verity in fe-safe at a Glance

- Removes the subjective decisions by the user, thereby increasing reliability and accuracy.

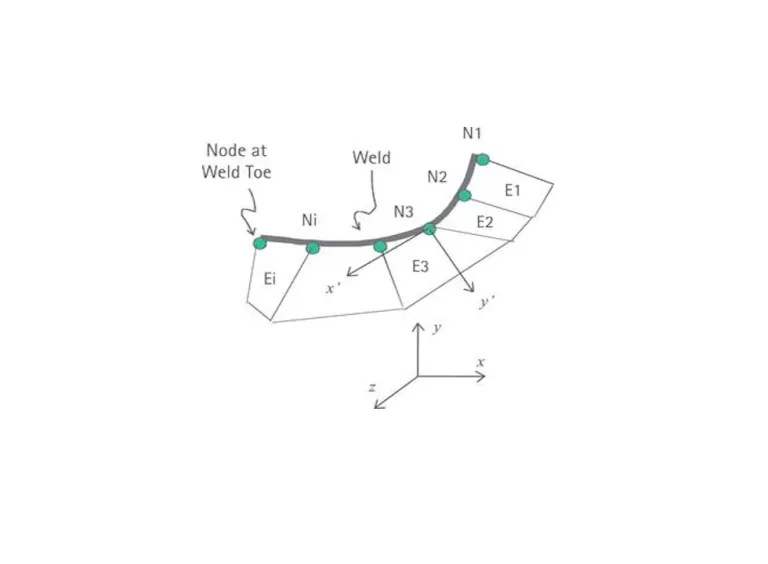

- Works from nodal forces at the weld lines, allowing coarse meshes to be used.

- Uses a single master S-N curve for all welds and for all thicknesses of sheet and plate.

- Offers consistent structural stress calculations regardless of mesh density or element types.

- Achieves new levels of accuracy and reliability.

- Applicable to all types of welds, including spot welds, and all types of loading, including random vibration and sine sweep loading.

- It is easy to use and automate.

- Analyzes welded joints, spot welds and non-welded areas in a single run.

- Validated by Battelle's Joint Industry Project using more than 3500 physical fatigue tests.

The Verity Module in fe-safe is an add-on module to fe-safe.

Verity in fe-safe Capabilities

- The use of nodal forces makes Verity much less sensitive to mesh density than standard FEA stresses and offers consistent structural stress calculations regardless of element types or finite element software used - a critical step to realizing Six Sigma in CAE applications.

- A single master S-N curve for steels and another curve for aluminum can be used for all welds, be they structural welds, seam welds, or spot welds, for all thicknesses of sheet and plate and for all types of loading.

- There are no subjective decisions that the user needs to make.

- Usable with coarse meshes of solid or shell elements.

- Allows the option of further improving the accuracy of fatigue life predictions by allowing the user to formulate their own custom master S-N curve based on proprietary data.

- Is supported by third-party tools from Altair, ANSYS and BETA CAE Systems for simplifying the definition of weld domains.

- The "Auto-Detect" tool for spot welds automatically detects the number of sheets welded together, the thickness of each sheet, and the location of each spot weld. Obtain short analysis times even with models that contain many thousands of spot welds.

Verity in fe-safe Benefits

As the original, patented Structural Stress Method, Verity is the most well-validated of all the Structural Stress approaches. Key Benefits include:

- Removal of subjective decisions by the user, thereby increasing reliability and accuracy.

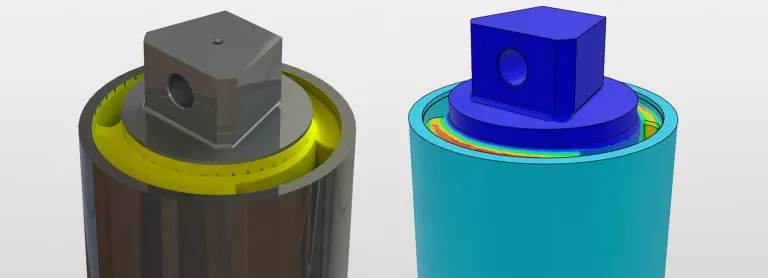

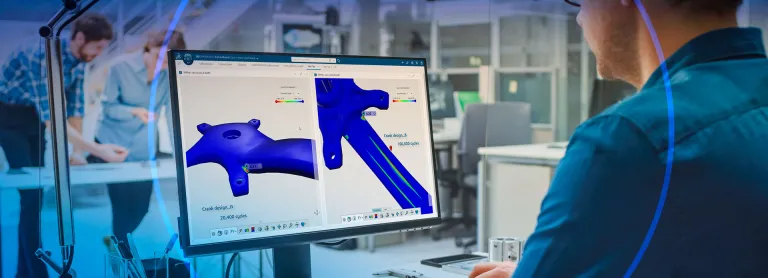

- Welded joints and non-welded areas can be analyzed in a single run, and the results are displayed on the same contour plot, thereby speeding up whole model analyses.

- Significant reductions in CAE and FEA modeling time.

- Lower development costs, minimizing the need for physical validation testing.

- Inspecting and testing components against fatigue criteria can lower "classification" or regulatory compliance costs.

- Optimized designs and lighter structures lead to less reliance on over-designing to account for uncertainty.

- Direct interfaces to leading FEA suites such as Abaqus, ANSYS, and Nastran (MSC, NEi, NX) are driven from an intuitive, single screen, Windows-based GUI.

- The "Auto-Detect" tool for spot welds enables fast fatigue analysis setup for models containing thousands of spots welds.

Verity was validated for applications ranging from the automotive to offshore/marine industries, through collaboration with leading engineering companies who were members of Battelle's Joint Industry Project (JIP). The effectiveness of the method has been demonstrated by collapsing into a single curve many thousands of fatigue tests from lab specimens and full-scale components, obtained and verified from open literature. This is the ‘master S-N curve.'

Verity has received many prestigious awards including TIME Magazine's Math Innovators (2005), Aviation Week and Space Technology's 2004 Laurels Award; and SAE's Henry Ford II Distinguished Award for Excellence in Automotive Engineering (2003). Business Week dubbed Verity as "A Bolt of Genius in Welding" (2004).

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering