ControlBuild

Designing Automation and Embedded Control Systems

Design and Validate Software for Control Systems

Modern products rely on sophisticated embedded electronic equipment, automated systems, and communication networks. The Control & Monitoring system constitutes more than 30% of total costs in Trains, Railways, Automotive, Energy, and more (Life Sciences, Water Treatment, Industrial Equipment, Food & Beverage).

ControlBuild is an innovative environment for designing & validating distributed control and monitoring systems. It models, simulates, tests, and deploys IEC 61131-3 control applications with higher efficiency, supporting Industrial Automation Plants (PLC and DCS based controllers) and Real-Time Embedded Systems (Railway Control & Monitoring).

ControlBuild creates distributed automation for trains, ships, devices, power plants, process units, and manufacturing lines. Compliant with IEC-61508 and EN-50128 safety standards.

ControlBuild, a Game Changer

ControlBuild is a dedicated development tool for design and integration tests. Model software specs, create breakdown structures, and design function behavior. Define hardware architecture, map control functions on PLC/ECU, allocate interfaces on IO cards and networks. Generate source code for major PLC/DCS or RT controllers (including railway safety-certified software) and design specifications & CD for suppliers. Reuse models and test patterns for VC, FAT, HIL, and OTS. Optimize your control system development with ControlBuild.

Key Advantages of Automation Control Systems

- Customer Values: Our customers seek higher efficiency in control & monitoring systems to meet stringent production constraints, enhancing performance at all levels. We reduce time-to-market by 50% and on-site test costs by 3x.

- Business Challenges: Validating specs early, covering the whole development cycle with a comprehensive toolchain for Automation Engineers.

- Supporting Integration: We support diverse PLCs & controllers, ensuring seamless compatibility and optimal system performance. Trust us for advanced automation solutions.

Industry Uses Cases of Automation Control Systems

ControlBuild offers different types of features and services depending on the sectors (railway, processes, manufacturing, energy, etc.) and the stage of the cycle in development and validation. Here are some examples of use cases.

- Railway

- Automation

- Virtual Comissioning

- Test Benches

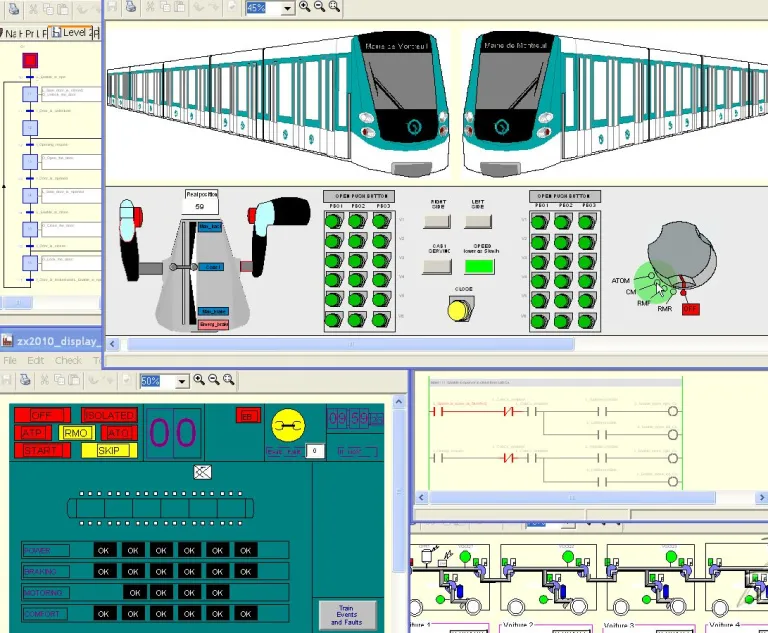

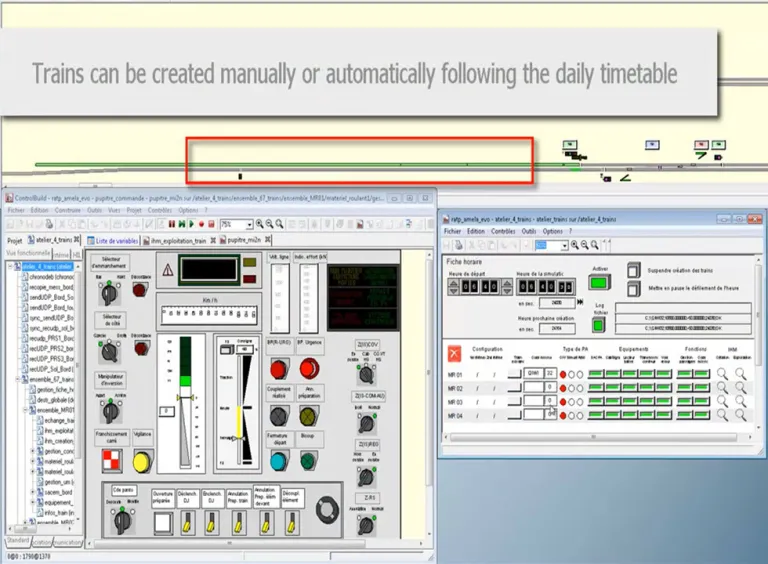

Design Software for Railway

ControlBuild: A comprehensive tool suite for Real-Time Embedded Systems, especially in Railway, compliant with EN-50128 Railway Safety Standard. It supports:

1. Software modeling to validate control system specs (e.g., traction, signaling) with stakeholders.

2. Hardware architecture definition, controller allocation, and data exchange setup.

3. Code generation and documentation for sub-system suppliers.

4. System validation, including behavior and network traffic simulation.

5. Reuse of models for HIL testing, operator training, and maintenance.

ControlBuild streamlines development while ensuring compliance with safety standards. It guarantees hardware-independent software, promoting flexibility. It offers a Virtual Twin for comprehensive control system management, including interfaces, maintenance, incident simulation, and change impact assessment.

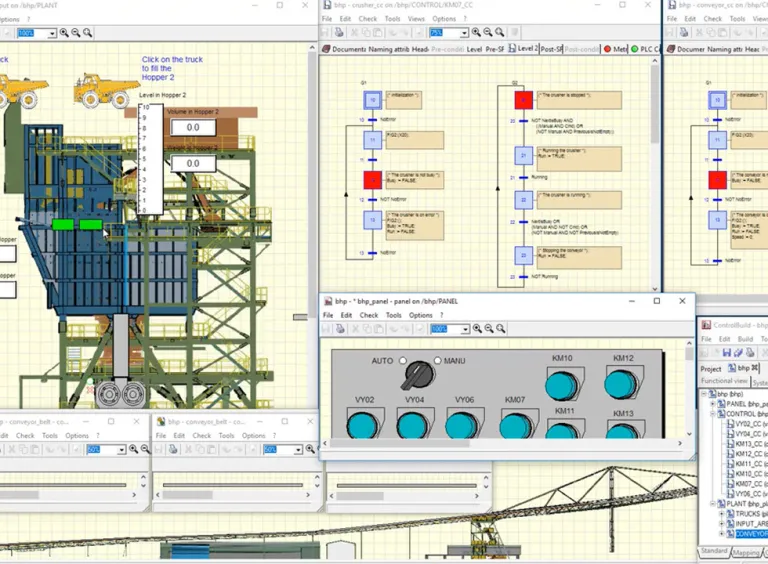

Design Software for Automation

ControlBuild: An integrated tool for industrial automation control system development in various sectors like Automotive, Energy (Wind, Hydraulic, Gas, Nuclear, Grid), Pharmacy, Water Treatment, and Food & Beverage.

Features:

Design and model control systems for early validation with stakeholders.

Define hardware architecture and controllers, allocate functions, and set up data exchange.

Generate code for PLCs, DCS, or ECUs, or create specifications for suppliers.

Reuse models for testing, operator training, and maintenance.

ControlBuild streamlines development, enhancing quality and safety compliance. It ensures hardware independence, allowing flexibility in selecting manufacturers. The virtual model becomes the system reference, empowering end-users for equipment management, interfaces, maintenance, incident simulation, change assessment, and competency management.

Virtual Comissioning

ControlBuild streamlines test, validation, and commissioning with Real-Time Plant Simulation linked to PLC/DCS and SCADA systems. Features:

Model manufacturing lines, power plants, and process units with libraries for handling, electric, fluidic/pneumatic components. Customize libraries with discrete/dynamic components. Connect to various PLC/DCS brands via configurable communication modules.

Using ControlBuild in Virtual Commissioning detects faults early, cuts costs, and speeds On-Site Commissioning. It provides realistic plant models, enabling testers to mimic real systems. Simulated control system changes reduce plant downtime and costly updates. The Virtual Twin permits safe testing of expensive or risky procedures.

Test Benches

Modern products rely on complex electronic equipment, automated systems, and networks. ControlBuild aids in testing, validation, and certification by connecting Real-Time System Testers to physical controllers and monitoring systems.

Features:

- Model behavior of sub-systems and unavailable controllers virtually.

- Define hardware architectures, Real-Time Targets, allocate models, and set up communication with Systems Under Test.

- Deploy simulators on real-time targets, monitor tests manually or automatically using predefined procedures linked to requirements.

ControlBuild serves as a Virtual Test Bench, detecting faults early, reducing costs, and shortening integration and qualification times.

Start Your Journey

The world of ControlBuild is changing. Discover how to stay a step ahead with CATIA

Join the conversation in the CATIA MBSE Cyber System User Community!

ControlBuild FAQs

An excellent example of automation control is a home thermostat system used for regulating temperature. This system operates as a closed-loop control system, one of the fundamental types of automatic control systems.

Also Discover

Learn What CATIA Can Do for You

Speak with a CATIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right CATIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering