Rapidly Changing Green Manufacturing Expectations

The climate agenda is no longer an option, it’s an imperative, and manufacturers are facing renewed pressure to move to a world of green manufacturing.

Does your business just talk big on sustainability, or does it have a clear plan of action?

What’s happening?

There are no two ways about it – when it comes to climate change, manufacturing industries are some of the biggest culprits. According to data from the World Research Institute, industrial energy use is the single largest carbon emitter in the world, responsible for nearly a quarter (24.2%) of total GHG emissions.

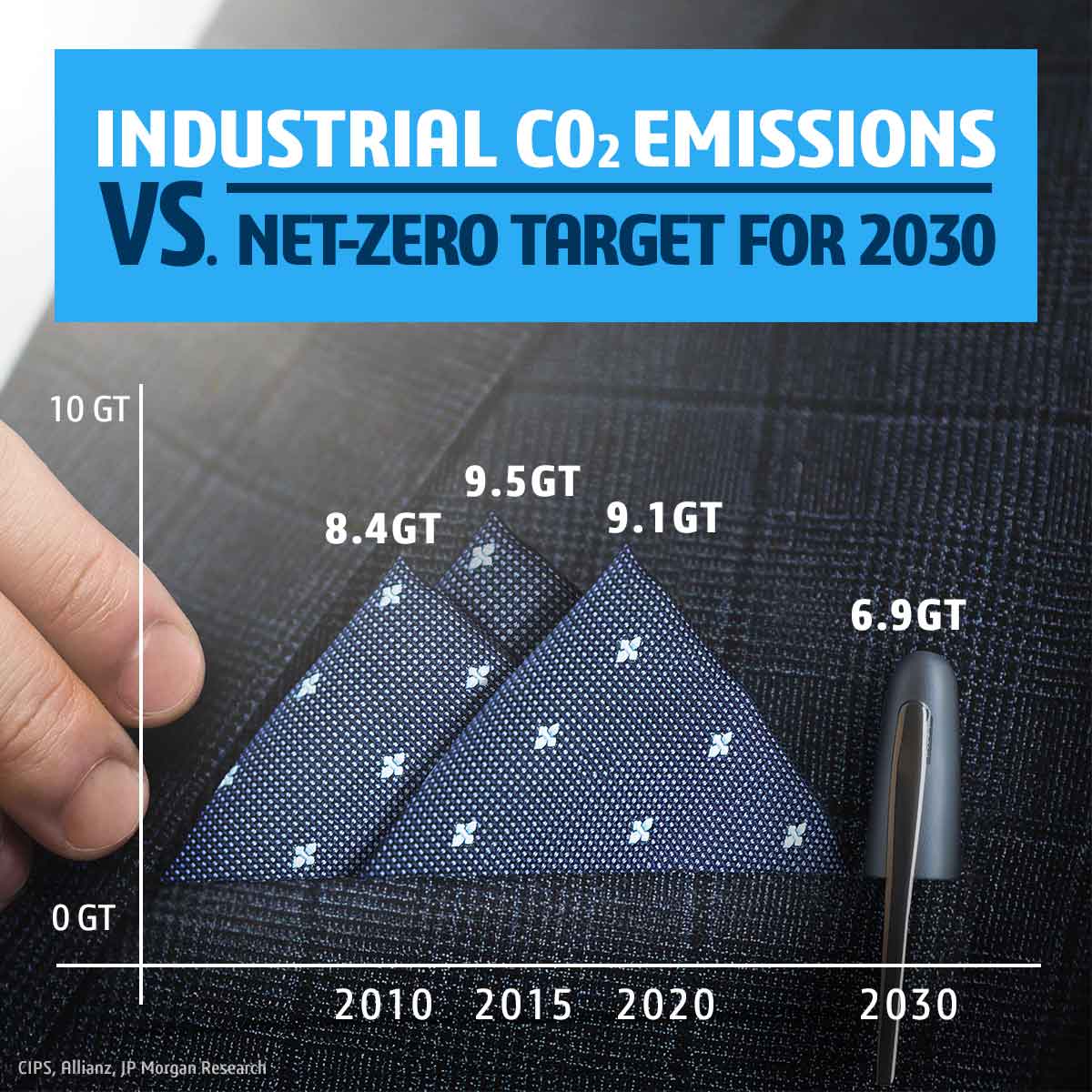

For the world to stay within the limits set by the Paris Agreement, consultant BCG estimates that emissions from production and logistics will need to decrease by approximately 45% by the end of the decade. All eyes are therefore on manufacturers to show that they are cleaning up their operations, facilitating an effective net zero transition, and becoming truly green manufacturers.

The pressure is coming from multiple directions. Governments, for one, are increasingly proactive in pushing for substantive change. For example, the EU’s “digital product passport” will mandate companies doing business in the EU to disclose information about product makeup so that they can be more effectively recycled – putting commercial and disclosure pressure on companies.

Consumers too are demanding more from businesses. One IBM survey found that 78% of customers preferred “clean” products, and 72% preferred environmentally responsible products. Even investors are getting in on the action. Around 75% of investors believe companies should address ESG issues, even if doing so reduces short-term profitability, while 49% would divest from companies that aren’t taking action.

And a collapsing climate is bad for business in ways that stand apart from the concerns of third parties. Climate-related extreme weather events, like floods or wildfires, are on the rise and can damage the supply chains on which manufacturing depends. Hot weather even affects power generation: Recently, nuclear power stations have had to slow their output because of lack of water to cool generators.

Curious about how other manufacturing industries respond?

Respond to today's challenges with our bespoke solutions

Why does it matter?

Jonathan Dutton, Marketing Director, Sustainability at Dassault Systèmes, is frank about the scale of the challenge for the manufacturing industry. He argues, “In order to stay on track with the Paris Agreement, we must collectively halve our GHG emissions by 2030, and drop to net-zero emissions by 2050. We are definitely not on track to do that today. There’s a massive challenge ahead of us, but there are also huge opportunities for manufacturing industries.”

In practical terms, there are several ways industries can pursue green manufacturing goals:

1. Optimize efficiencies throughout their operations, with the aim of eliminating or reducing waste materials and resources. As Dutton remarks, “The most sustainable energy is the energy you don’t use”

2. Increasingly electrify their processes so more of their facilities can run on greener, low-carbon forms of energy generation, for carbon neutral manufacturing

3. Focus on designing and producing more sustainable, eco-friendly products

4. Work to develop circular economies by prioritizing recycling and reuse, where materials are kept within this system rather than being extracted and discarded.

Of course, innovative sustainable manufacturing practices are harder to develop and integrate in some industries than others. But often these are the sectors where it can make the most difference. The carbon-intensive steel and cement industry, for instance, is hard at work trying to develop and scale hydrogen-based reduction processes, that could help decarbonize an infamously dirty sector. The same could be said for the transportation industry and the aviation industry.

To adapt to our new climate reality, manufacturers must also work to transform operations for more unpredictable weather patterns. “We have to adapt to climate change, because it's going to happen anyway,” says Dutton. “For example, we must ask: Are today's supply chains equipped to manage extreme heat fluctuations? Can they adapt to unpredictable shortages or failures? Can employees and machines function when it's 50 degrees Celsius outside?”

How can I prepare?

Managing a challenge as complex and multi-faceted as climate change means it’s more important than ever to establish an accurate and comprehensive understanding of the lay of the land.

“Product and manufacturing engineering is becoming more complex than ever, especially now that a given product’s environmental footprint needs to be included in the early design phases,” says Dutton. "Much more sophisticated digital tools are needed.”

Managing this complexity may mean that would-be sustainable industries increasingly come to rely on digital tools, whether that means expanding insight into operations, or innovating with sustainable products and processes. According to the Financial Times Focus report, 26% of businesses are adopting advanced digital tools to help them design and build lower-carbon products.

There are two key benefits to this approach: The ability to measure and monitor the footprint of existing operations and products; the opportunity to model and test new ideas and ways of working. An example of this in action is the rapid growth in offshore wind farms. Digital tools have enabled designers to create larger, more efficient, and more resilient turbines by carrying out tens of thousands of simulations during the design stage and then constantly monitoring performance during its operation.

“Technology is a powerful way to validate any sustainability claims and is critical in winning the trust of investors, regulators and customers,” says Tom Acland, CEO at 3DEXCITE, Dassault Systèmes.

Manufacturers have a colossal task ahead of them – creating sustainable, accountable, circular value chains. To do so, will require rethinking how they operate, both individually and together. Having the necessary tools at their disposal to find the right solutions will be crucial.

“This is the challenge that we have in front of us today. If we embrace new models, methods, tools, and skills we’ll come out more resilient, protecting both our businesses and the planet on the way,” says Dutton.

Are today's supply chains equipped to manage extreme heat fluctuations? Can they adapt to unpredictable shortages or failures? Can employees and machines function when it's 50 degrees Celsius outside?

Other Trends

Discover more with our Manufacturing Industries

- Aerospace & Defense

- Consumer Packaged Goods & Retail

- Home & Lifestyle

- High-Tech

- Industrial Equipment

- Marine & Offshore

- Transportation & Mobility

Discover how the 3DEXPERIENCE® platform drives innovation in the industry with CPG solutions for design, simulation and AI-driven forecasting.

Innovate every step of your sustainable packaging journey, driving profitability with an end-to-end strategy, powered by the 3DEXPERIENCE® platform.

Simplify and accelerate innovation to create more valuable consumer experiences.

Discover how high-tech manufacturers can sharpen their sustainability strategy to go beyond e-waste recycling and achieve regulatory compliance, zero-waste operations and efficient product recovery

Accelerate the sustainable transformation of the Marine & Offshore industry.

Re-engineering your thinking as well as your technology will open your business to extraordinary opportunities.

Driving vehicle innovation toward the mobility of the future

See how the Virtual Twin strategy enables automotive innovators to develop high-performance, zero-emission, recyclable vehicles

THE WORLD NEEDS MANUFACTURERS

A MANIFESTO FOR CHANGE