Raphe mPhibr

The 3DEXPERIENCE platform supports the India-based company in engineering over 100 unique intellectual property breakthroughs across robotics, aerospace and advanced materials.

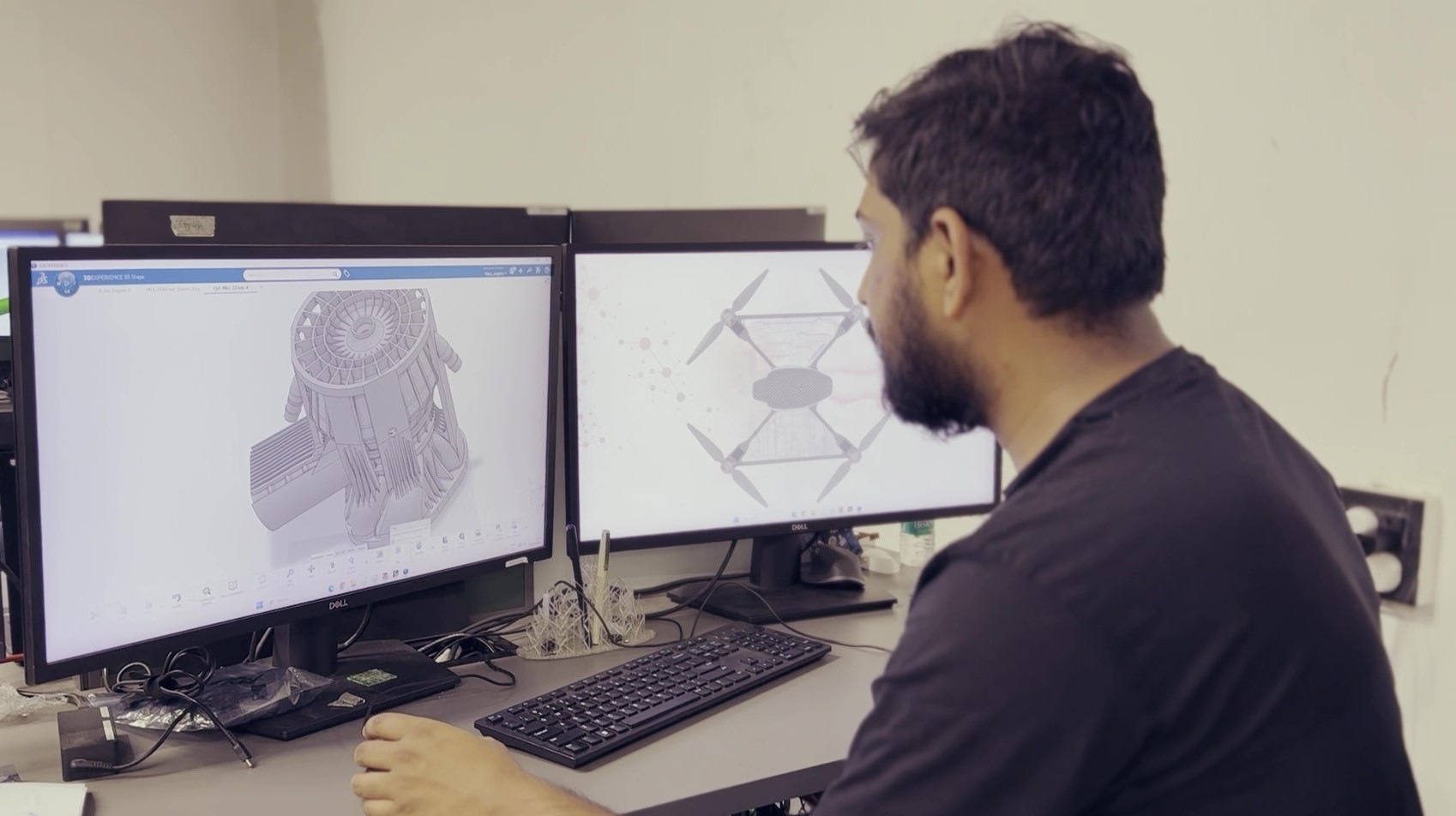

Reshaping Unmanned Aerial Vehicle Design

In less than a decade, India-based aircraft manufacturing company Raphe mPhibr (Raphe) has grown from a two-person startup to a company that’s worth almost US$1 billion, employing over 500 people. Spend just a short time with its founder and chairman Vikash Mishra, and it’s easy to see why the company has experienced such rapid success. A self-made entrepreneur from a remote village near Prayagraj in India, Mishra is highly driven and has a wealth of expertise. He holds physics, mathematics and mechanical engineering degrees from the University of Arkansas at Fayetteville and embarked on a PhD in nuclear engineering at the Massachusetts Institute of Technology before founding Raphe in 2016.

Raphe’s vision is unique. Unlike other unmanned aerial vehicle (UAV) developers, the company set out to rethink aerospace design and development from the ground up, prioritizing physics, performance and manufacturability over legacy methods. This required more than incremental progress. It called for a complete transformation in how aircraft systems are conceived, validated and built.

“We have spurred a revolution in India by indigenously developing and manufacturing every subsystem used in our UAV,” Mishra said. “Our products range from lightweight agile surveillance drones for monitoring crops or livestock, to high-endurance heavy-lift logistics drones used to deliver supplies to remote or dangerous areas.”

While it would be easy for Raphe to source subcomponents for its UAVs from across the world, Mishra believes this approach would dampen his company’s potential. “As soon as you take those subcomponents and try to design a system, you have already constrained yourself,” he said. “That’s why Raphe is creating everything itself – new engines, new materials, the airframe, the electronic speed controllers, microcontrollers, flight controllers – we design and manufacture it all in-house, and without any restrictions on our imagination.”

According to Mishra, this philosophy extends to how Raphe’s products are conceived from day one: designing for need, physics, manufacturing and quality – not just for form or function. Every component is engineered with its final performance and manufacturability in mind, ensuring that the end result meets both mission demands and production feasibility.

“We have facilitated these proprietary capabilities thanks to our adoption of Dassault Systèmes’ 3DEXPERIENCE platform,” Mishra said.

We needed the best software to help us create our vision. Because it’s only when you can show what you can do, that the world will believe it.

Best-of-breed Software for Complex Product Development

Raphe recognized Dassault Systèmes’ solutions, including CATIA and SOLIDWORKS for design and SIMULIA for simulation, as best-of-breed software that could easily handle the complexities of developing a UAV.

“Designing and manufacturing a drone is nothing less than designing and manufacturing a whole aircraft,” Mishra said. “The kind of drones we are manufacturing have 20,000 to 30,000 parts. We needed the best software to help us create our vision. Because it’s only when you can show what you can do, that the world will believe it.”

The company implemented the platform with support from Dassault Systèmes and its local partners. EDS Technologies assisted with platform configuration and provided support for simulation capabilities, while SOLIZE India helped with design functionality. “The support we got has been incredible,” Mishra said. “I can reach out to our partners any time, and they will pick up our call and solve our engineering challenges. Everyone is committed to ensuring we get the full value of these solutions.”

Accelerating Design Optimization

With the 3DEXPERIENCE platform, Raphe has been able to substantially optimize the design process of its drones.

“The first step a designer takes when engineering our products is to create what we call a ‘first good guess’ in CATIA,” Mishra said. “CATIA allows us to think in 3D – not in straight lines, circles or squares. If you think about the biological systems that have evolved in nature – such as plants, anatomical structures and geological formations – they are not made up of geometrical shapes. So, using CATIA, we can design more organically and without limitations.”

Raphe’s engineers then use SIMULIA to validate the design early in the process. For example, it can simulate a drone’s load-bearing or aerodynamic properties. “If the simulation shows that our design will fail to achieve what we want it to, we will start a new iteration cycle in CATIA,” Mishra said. “We might go through this process a few times, making tweaks or changing parameters. Then we continue the workflow in SOLIDWORKS, which we use to optimize our designs for 3D printing.”

Designing with CATIA has helped Raphe to move beyond the limitations of CNC (computer numerical control) machining and casting. As a result, it has been able to design its first prototype drone – the mR10-IC – with advanced geometries, such as gyroids and cycloids, which are purpose-built for 3D printing. “We’ve designed the fuselage, ribs and spars using generative shape design in CATIA, which has allowed us to create unique geometries that reduce drag and optimize aerodynamics,” Mishra said.

These aren’t the only distinctive attributes of the mR10-IC. By leveraging the 3DEXPERIENCE platform, Raphe has engineered over 100 unique intellectual property (IP) breakthroughs across robotics, aerospace and advanced materials, including a 600g four-kilowatt two-stroke internal combustion engine (ICE).

“A traditional UAV engine typically weighs 4 to 5kg,” Mishra said. “Using the 3DEXPERIENCE platform, we were able to make the whole engine 600g. As a result, the mR10-IC is lighter and has more power than a drone with a four-stroke ICE. In fact, it outperforms systems seven times its weight.”

What’s more, by working in the virtual world instead of creating costly physical prototypes for each design iteration, the development process has been completed in record time. “The development cycle for this type of drone would typically take years,” Mishra said. “By using the 3DEXPERIENCE platform, we have reduced that to just three months.”

Scaling the Future of Unmanned Aerial Vehicle Design

By deploying the 3DEXPERIENCE platform to accelerate its time to market, Raphe is on track to become a global leader in unmanned aviation. “We have already filed over 40 patent and design applications,” Mishra said.

And there’s a lot more to come. Raphe has recently inked a new deal with EDS Technologies that will see it further benefit from Dassault Systèmes’ complete portfolio of solutions. The company has expanded to additional roles in CATIA for composite and electric harness design. It will also extend on SIMULIA to respond better to compliance efforts with capabilities for electromagnetic interference and electromagnetic compatibility. And ENOVIA’s full range of capabilities including configuration management, version management and product data management will provide Raphe with end-to-end product lifecycle management.

Moreover, Raphe’s new world-class research and manufacturing facility is nearing completion and will further enhance its capabilities, including cutting-edge additive manufacturing technology. Here, DELMIA will provide it with manufacturing planning and additive manufacturing capabilities.

The company also plans to expand to over 1,200 employees in the next six months, and Mishra believes the 3DEXPERIENCE platform will be integral to its ability to scale.

“We are currently in talks with Dassault Systèmes about how to co-create an internship program to quickly train our future workforce on CATIA,” he said. “This approach will equip a new generation of engineers with the skills needed to drive innovation in unmanned aviation. We are also exploring how we can leverage more of the platform’s functionality – including ENOVIA to better manage certification data and DELMIA to virtually plan manufacturing – to further enhance our business. It’s been a great journey so far, and I expect our partnership to continue long into the future, expediting the use of drones across the world.”

Discover more about the Co-Design to Target, Program Excellence and Winning Concept industry solution experiences.

Focus on Raphe mPhibr

Raphe mPhibr is an aircraft manufacturing company specializing in fully customized, end-to-end unmanned aerial vehicle (UAV) systems built entirely in-house. The company has spurred a revolution in India by indigenously developing and manufacturing every subsystem that goes into a UAV. With over 500 employees, a world-class research and manufacturing center, and a team that includes bright minds trained at MIT, Georgia Tech, and IIT, Raphe has become a hub for innovation in India and beyond.

For more information: www.raphe.com

Focus on EDS Technologies

EDS Technologies, with over 30 years of experience, delivers technology solutions that drive digital transformation across manufacturing, high tech, defense, infrastructure, natural resource, and retail sectors. Headquartered in Bengaluru, India, it is a partner of Dassault Systèmes and the largest PLM solutions provider in India, with a customer base of more than 2,000 customers. It addresses the needs for virtual twins for design and manufacturing, business dashboarding for real-time decision-making, 3D printing for manufacturing, electronic design automation, and IP solutions for chips and SOC designs.

For more information: https://edstechnologies.com/

Focus on SOLIZE India

Founded in 1992, SOLIZE India has a mission to enable the nascent engineering industry in India to adopt digital methodologies for solving complex engineering problems. The company has been an essential partner in almost all product development programs of the major industry players in India. SOLIZE India has also been actively working with the top engineering universities in India, helping them to set up design infrastructure and providing knowledge and skill development support.

For more information: https://www.solize.com/india/