BOM: Bill of Materials for Driving Product Lifecycle Excellence

A detailed breakdown of components and resources for manufacturing processes.

What is a Bill of Materials?

A Bill of Materials (BOM) is a structured list of components, raw materials and sub-assemblies required to manufacture a product. It provides a detailed breakdown of the parts, quantities and relationships between components. A BOM is crucial to ensure consistency, reduce errors and optimize production efficiency across industries.

Key Benefits of Bill of Materials

Sustainability and Bill of Materials

A Bill of Materials plays a critical role in supporting sustainability by encouraging efficient material usage and waste reduction. By tracking component lifecycles, businesses can design eco-friendly products, optimize recycling processes and comply with environmental regulations. Digital BOMs reduce paperwork and streamline sustainable manufacturing practices.

Bill of Materials Management across Industries

Various industries can benefit from the BOM management, to optimize production efficiency and ensure product quality. Here are examples of how various industries can benefit from the BOM management:

Driving Innovation with Dassault Systèmes’ BOM Solutions

Leverage the power of Dassault Systèmes’ advanced Bill of Materials' solutions to boost efficiency and improve collaboration.

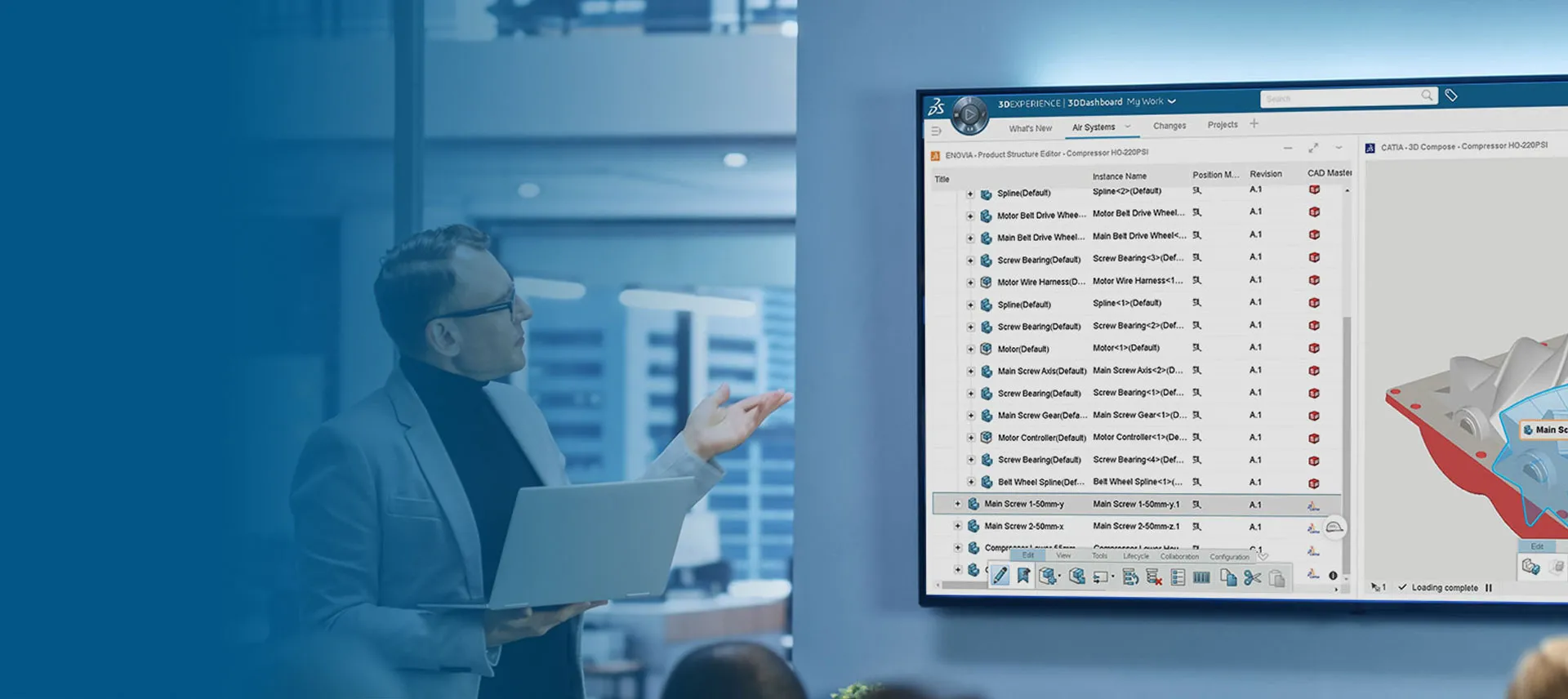

ENOVIA for BOM Management

Centralize and manage Bill of Materials data efficiently to ensure collaboration and compliance across global teams. ENOVIA provides a single source of truth for BOM management, improving cross-functional perspective coordination and accelerating product development cycles.

DELMIAWorks Bill of Materials Software

Streamline manufacturing processes with an integrated BOM solution that improves material management such as tracking, cost control and efficiency. It helps businesses automate BOM updates, reduce errors and integrate real-time data for improved decision-making.

DELMIAWorks Quality Management

Ensure BOM accuracy and compliance with automated quality control measures to reduce errors and optimize product consistency. It integrates quality checks within the manufacturing process, ensuring defect-free production and regulatory compliance.

Experience the Real-World Value of BOM Management

Discover how global companies are using BOM solutions to achieve operational excellence.

Use Cases: Key Business Functions of a Bill of Materials Software

Learn how a Bill of Materials optimizes key business operations, from product design to production efficiency.

EBOM for Product Development

An Engineering BOM (EBOM) plays a vital role in the early stages of the product lifecycle by capturing the design intent and technical specifications of a product. It serves as the foundation for engineering teams to define component relationships, manage design iterations and validate configurations before manufacturing begins.

MBOM for Production Execution

An Manufacturing BOM (MBOM) translates the engineering vision into actionable manufacturing steps. It includes not only the parts and materials required but also the tools, assemblies and instructions needed on the shop floor. MBOMs are essential for production planners and operations managers to coordinate manufacturing activities and minimize resource waste.

Cost Control and Budgeting

An accurate BOM helps businesses estimate material costs, track expenses and prevent budget overruns by optimizing resource planning. It ensures real-time visibility into costs for better financial forecasting and profitability analysis.

Supplier Coordination

A structured BOM provides suppliers with clear specifications, reducing lead times and improving procurement efficiency. It improves material management collaboration, mitigates supply chain risks and ensures the availability of high-quality components.

Compliance and Regulatory Assurance

A BOM ensures manufacturers adhere to industry-specific regulations by maintaining accurate records of materials and components. It improves traceability, reporting and maintains records required for audits and certifications.

Enhancing a Bill of Materials with Virtual Twins

Virtual twins take Bill of Materials (BOM) management to the next level by synchronizing design, manufacturing and service data in a unified digital model. They ensure the full traceability of components, validate configurations and facilitate real-time updates across teams. By integrating virtual twins with a BOM, companies will improve collaboration, reduce errors and speed up time-to-market while ensuring seamless version control.

Dassault Systèmes Bill of Materials Key Values

Innovation

Driving next-gen solutions for continuous improvement.

Compliance

Streamlining workflows for enhanced productivity.

Efficiency

Delivering tailored solutions for real-world manufacturing challenges.

Customer-centric Approach

Supporting eco-friendly, resource-efficient production processes.

Sutainability

Supporting eco-friendly, resource-efficient production processes.

Digital Transformation

Leveraging technology to optimize product lifecycle management.

Get in Touch with Our Experts

Get in touch with our specialists to learn more about tailored BOM solutions.