Recycling Plastics Isn’t Happening: Here’s How To Start

Our modern life relies on plastic and recycling it, is a challenge. But digital solutions can give you visibility and flexibility you need to build truly sustainable plastic value chains.

The world is awash with single-use plastic. Global production of primary plastic is forecasted to reach 1,100 million tonnes by 2050. And with that comes mountains of plastic waste – more than 400 million tonnes every year. This plastic then makes its way into our environment: Into our rivers, our oceans, and worryingly – via seafood – into us.

Recycling single-use plastics is therefore critical for the health of our ecosystems, and of ourselves. But while there’s lots of talk about greener plastics, the OECD estimates that less than 10% of plastic is actually recycled. What can we do in the face of such inaction?

Why is it Important to Recycle Plastics?

Plastic recycling faces significant challenges with only 9% of all plastics ever produced being recycled worldwide. As environmental concerns grow, businesses need effective solutions to transform plastic waste into valuable resources. Through advanced software and digital technologies, companies can now optimize their recycling processes, track material flows, and design products for better recyclability - helping create a more sustainable, circular economy for plastics.

How Can We Reduce and Recycle Plastic?

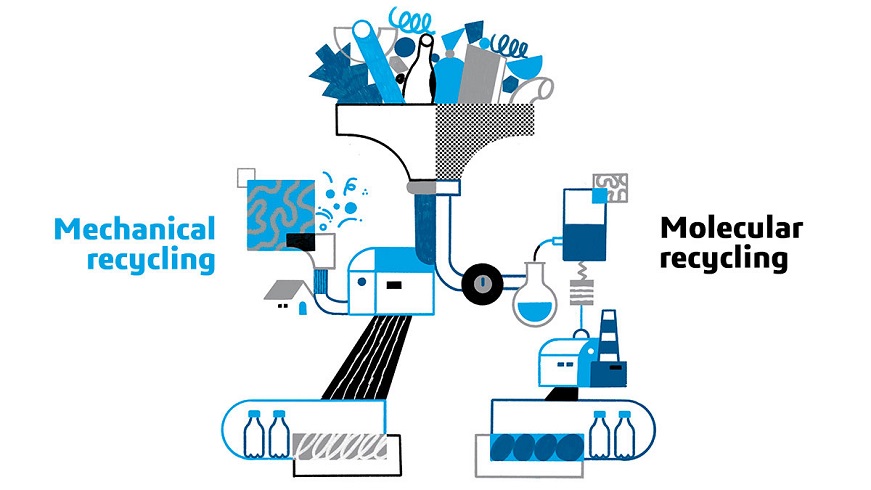

Thankfully, plastic recycling solutions exist. These fall into two main categories: Mechanical and molecular.

1. Mechanical recycling

This technique involves physically breaking down plastics so that they can be made into new products. It requires the mechanical grinding and crushing of plastics into pellets from which new plastics can be made.

However, while straightforward, mechanical recycling has its limitations. Products submitted for recycling need to be made of the same kind of plastic, otherwise the resulting new products can be low-quality, or even unusable.

This means laborious manual sorting and separation processes must be carried out before the recycling can take place. Processes which of course cost time and money.

2. Molecular recycling

Molecular recycling refers to a range of techniques that work on the molecular level of the plastics – that is, by breaking down the chemical compounds of which plastic is made and reconstituting them into new products.

Molecular recycling approaches are better able to handle mixed plastic loads and create more efficient yields. There are several different approaches:

- Feedstock recycling: Here, plastics are melted down and reformed. There are several different ways of going about this – pyrolysis, where plastics are simply heated; hydrothermal recycling, where a mixture of heat and water are used; and gasification, where plastics are converted into industrially useful gases.

- Chemical recycling: Here, chemical treatments are used to break down plastics from complex polymers into more simply polymers, through a process called depolymerisation. In practice, chemical recycling means the use of chemicals to wash away different layers of plastic, and is suitable for flexible and complex plastics, which are built up in layers.

However, as effective as these recycling methods are, they are currently underutilized. A more holistic approach is needed if they are to be fully leveraged. And that means manufacturers leveraging digital technologies to rethink their approach.

The success of plastic in packaging and products over the years makes finding a substitute very challenging. When it comes to food preservation, sterility, durability, stability etc., plastic is exceptional. Now there are a wide spectrum of plastics of different types and grades available. Combination of these in products and packages makes recycling very difficult.

Why Is It Difficult To Recycle Plastic?

Being mindful of recycling practicalities starts with design choices, helping create products whose lifecycle doesn’t just end with the consumer.

For example, if you are a manufacturer of a complex plastic product, it may contain multiple plastic components fitted together. To make it fully recyclable by mechanical methods, you need to evaluate whether you could use the same type of plastic for all your components, whether they are springs, casings, or bearings.

To do this, you want to be able to model and test these designs to see if they could work in real world scenarios and deliver the same quality as the existing product. Dassault Systèmes’ virtual twin solutions enable designers to create virtual prototypes and run multiple simulations to find out whether a particular plastic could withstand day-to-day operational stresses, be a cost-effective alternative, and how easily they could be broken down at end of life recycling facilities.

And many companies are already doing this. American-Australian packaging manufacturer AMCOR produces more than 20 billion plastic packaging products evert year, and has used Dassault Systèmes tools to stress design for reuse, and create resilient, sustainable plastic containers.

Visibility Across the Value Chain

The other challenge to overcome when it comes to making plastic reuse a reality is understanding the plastic product lifecycle across the entire ecosystem. Where along the journey might your recycling efforts breakdown?

For example, without the right recycling facilities, even the most well-designed plastics products can end up dumped into rivers or oceans. Highly recyclable products like biodegradable plastics sound good on paper but are only truly recyclable if the right infrastructure exists in target markets.

Dassault Systèmes 3DEXPERIENCE® platform provides businesses with full visibility across the value chain. So a product can be designed, manufactured, and sold with an understanding of the infrastructural recycling capacity of the geographies in which they are distributed.

The Sustainable Packaging Strategy That Unboxes Profitability

Explore the four critical stages below to uncover what’s inside a profitable, sustainable packaging value chain.

Rethink, Reduce, Reinvent: The Sustainable Packaging Solution

Rethink your approach to plastics

Towards a Plastic Circular Economy

Today, plastics manufacturers suffer from something called “value leakage”, where plastic products are lost to the system and the materials used to make them never come back.

True circularity involves the reduction, or even the elimination, of this leakage, so rather than relying on primary plastic, existing materials are retained and productively reused. This is where digital solutions can make a considerable difference, helping companies plan, test and realize a more sustainable system.

“From the molecular level to the macro level, we have the solutions that can help you validate the entire circular journey, so that you get it right the first time,” says Hrishikesh Mohan, Home & Lifestyle, CPG & Retail Industry Solution Technical Director at Dassault Systèmes. “We have what you need to successfully bring new, recyclable products and processes to market.”

How One Industry Leader Met The Challenges Of Sustainable Packaging

By implementing circular economy practices empowered by Dassault Systèmes’ innovative solutions, a major consumer goods organization reduced the environmental impact of millions of products while maintaining high-performance standards and meeting consumer demands.