What is visual management?

Visual management tools are a crucial part of implementing a Lean management system. Find out just how a visual management system can help you to manage your people and your projects more effectively.

What is visual management?

Most of us are not aware that we are surrounded by visual management tools every day of our lives. Traffic signs tell us how fast we can drive and what lanes to use, floor maps show us how to navigate our way through buildings, and commercial signage informs us where we can purchase goods and services. While they may seem like innocuous everyday items, these are all good visual management examples.

In the business world, visual management is a key Lean management technique. Visual management systems use intuitive visual aids to communicate information clearly, quickly, and concisely.

In most cases, visual management tools provide information on performance, expectations, and standards and can also be used to deliver warnings. They are designed so that people can get the maximum amount of data at a glance. Visual management tools help to prevent accidents or mistakes, provide people with key information on how a task is progressing, and enhance transparency and employee morale.

Discover all the Dassault Systèmes store solutions for visual management

Explore the effective and intuitive visual management solutions from Dassault Systèmes today. Visit the Dassault Systèmes store and access a range of innovative visual management tools like Delmia 3D Lean Team Player, Enovia Project Planner, and 3DSwymer.

DELMIA Lean Team Player

Make collaboration effective, intuitive and easy with a cloud-based whiteboard designed to fuel innovation

ENOVIA 3DSwymer

Connect employees, partners, suppliers, customers, consumers and regulators into a framework for sustainable innovation.

ENOVIA Project Planner

Reduce resource and overall project execution costs by enabling lean optimized team planning

How does visual management differ from other management techniques?

Visual management tools are primarily used to maintain visual control in Lean management systems. According to Lean management principles, every employee of an organization from the top to the bottom should be constantly striving to eliminate waste and enhance efficiency.

Effective visual management with Lean techniques means that instead of giving employees complicated progress reports or long-winded written instructions, managers instead provide clear, easy-to-understand visual cues that impart information instantly. These visual cues can be in the form of pictograms, charts, or boards.

What are the basics of visual management?

Implementing some basic Lean management techniques will help you to make the most of your visual management tools. Let’s take a look at some typical visual management techniques.

- Create a visual workplace

- Use visual controls

- Encourage collective decision making

Create a visual workplace

You can use a range of either physical or virtual visual devices to create an organized, efficient, and safe workplace. The purpose of the visual displays is to communicate important information about the company to all employees.

Use visual controls

Many companies have visual signals and metrics displayed on employees or company devices to control the production process or monitor the daily KPIs of the company.

Encourage collective decision making

Use visual tools during meetings between management and employees. Daily, weekly, or monthly reports can display metrics using graphs and other easy-to-understand pictorials. The use of such visual management tools should be used to spark discussion or start a brainstorming session.

What are the benefits of visual management?

Since everyone has access to the same level of information, visual management tools act to enhance communication within and between teams. They can improve efficiency, streamline processes, and help to reduce waste.

Visual management tools can be used to impart information quickly to your team during daily, weekly, or monthly meetings. They enable real-time decision-making, as they provide instant access to critical information.

Visual management tools also enhance safety by providing clear warnings and instructions. They can boost organizational performance and promote continuous improvement. Crucially, visual management tools can increase employee engagement and give them a sense of control over their work, raising morale and job satisfaction levels.

What are the tools used in visual management?

To be effective, visual management tools need to be easy for anyone to comprehend, regardless of whether or not they are familiar with an environment. People should need no special knowledge to understand the message or intent of a visual management tool.

The 5S system and color coding

The 5S visual management system is a lean technique based on the five S principles of sort, set in order, shine, standardize, and sustain. It uses color coding and labels to mark locations and manage inventory. While the 5S system is simple to understand and easy to implement, it can often be too rigid for dynamic working environments.

Kanban boards

Kanban boards are a workflow visualization tool. They can be in digital or physical formats and use columns and sticky notes to show how a project is progressing. A Kanbanize board is a highly useful tool but must be kept updated regularly to be effective.

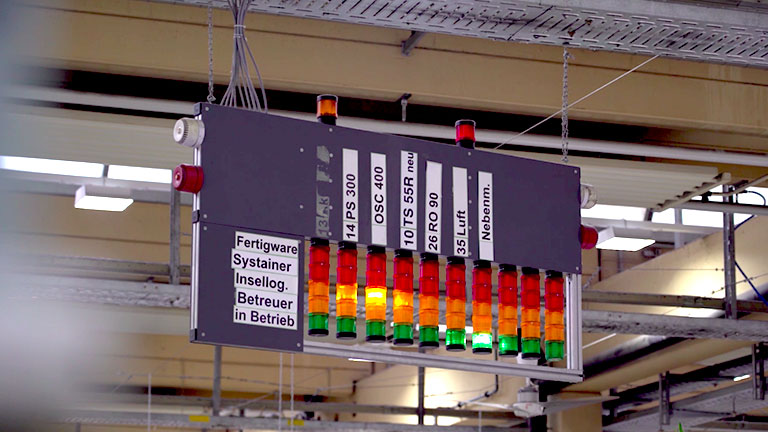

Andon lights

Andon lights are most commonly found in factories or on machinery. They work in the same way as traffic lights with red signifying operations have stopped, yellow signifying operations have temporarily ceased, and green signifying that operations are in process. Andon lights can also be used to designate the need for maintenance or more materials. The drawback of Andon lights is that they do require interpretation to be understood properly.

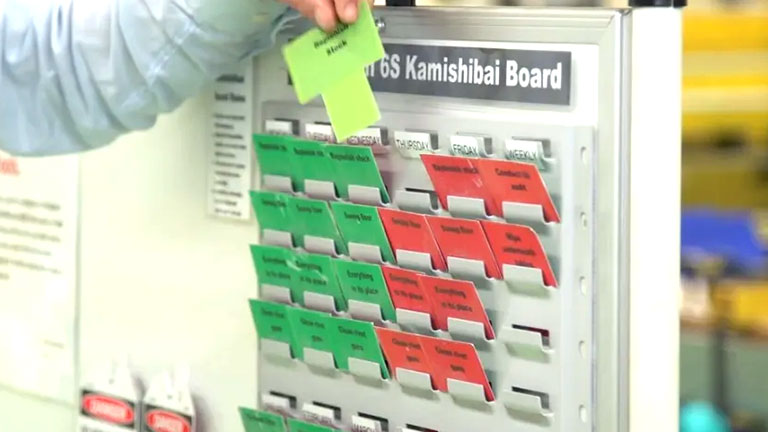

Huddle boards

Huddle boards provide information on a certain task that a team must complete. They are usually used in agile management systems. Often, a huddle board will use the SQCDP board format or be organized as a Kamishibai board. Huddle boards make it simple to see the progress of a project or task, but as with Kanban boards, if they are not kept up to date, they can convey incorrect information.

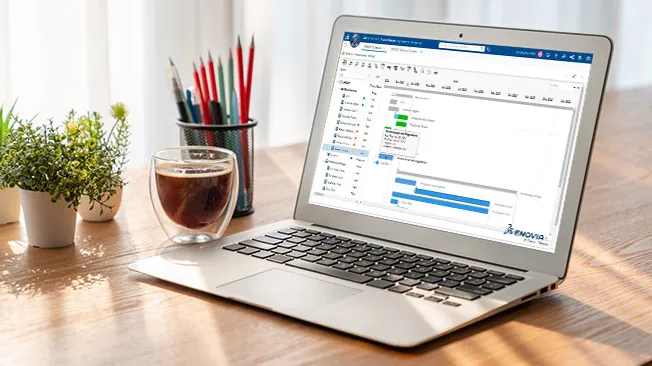

Gantt charts

Many managers will use a visual Gantt chart to monitor the progress of all the tasks needed to complete a project. A Gantt chart has a list of activities that must be completed on the left and a timeline on the right with bars that represent each task and what team it is allocated to. Gantt charts provide information at a glance on the status of a project but can easily become overly complicated and take a long time to set up without the right software.

Classical whiteboard or post-it board

The classic whiteboard or post-it board is used in offices and enterprises throughout the world. Simply, managers will put pertinent information on the board and display it prominently in the workplace. While this kind of visual management board can convey information easily, whiteboards and post-it boards can become outdated or complicated without the right organizational system in place.

Browse all the Dassault Systèmes store applications

We feature in our store some of our best software to design, collaborate and innovate throughout the entire product lifecycle.

Content related to visual management

Industries where visual management tools are used

Visual management tools can be found in any industry where important information must be provided to employees quickly and clearly. Lean manufacturing visual management tools are used to improve efficiency, quality, and safety. Visual management tools are used in the healthcare sector to improve patient care, reduce errors, and optimize processes.

Construction sites often have visual management tools to track progress, manage schedules, and ensure safety measures are in place. Visual management tools are used for supply chain management purposes to track inventory, monitor shipments, and optimize transportation. Retail outlets also often have visual management tools to manage inventory, improve store layouts, and enhance customer experiences.

Implementing visual management in an organization

Implementing a Lean manufacturing visual management system within an organization requires a considered and orderly approach if it is to be effective. While every workplace is different, managers usually follow the below steps.

- Getting started with visual management

- Be aware of the importance of leadership

- Provide training and ongoing education for employees

Getting started with visual management

Before you implement a visual management system, you will need to clearly define your goals and objectives and choose the appropriate tools and techniques to accomplish them. Managers will need to assign responsibilities to employees and provide training to ensure that tasks can be carried out effectively.

Be aware of the importance of leadership

Business leaders must communicate their vision and the benefits of visual management. They need to realistically set expectations for visual management implementation and allocate resources for visual management initiatives. It is worth keeping in mind that good leaders always lead by example, so managers must be sure to adhere to workplace regulations.

Provide training and ongoing education for employees

Employees may require training on the use of visual management tools and techniques. They should be provided with ongoing education and support. Employee engagement and feedback should be encouraged. Visual management should also be incorporated into new employee onboarding.

Using digital visual management tools for better collaboration

There are many benefits to using digital visual management tools to enhance collaboration and communication. Visual management tools give people real-time access to information. They can be positioned so they are visible to all employees, for instance, as an app on corporate mobile devices. Visual management tools are easily scalable for bigger teams. Data backups and history can be more easily managed and kept up to date with digital visual management tools.

Visual Management tools - Conclusion & Perspectives

Businesses require their teams to be kept informed of all developments and regulations in a clear, concise, and easy-to-understand manner. Visual management tools can be used to ensure that your team knows instantly exactly what they need to know about the status of a project, safety regulations, how to operate equipment or general work rules.

Visual management tools are crucial to any Lean management system. With the right visual management systems in place, you can boost productivity, reduce waste, enhance safety, and increase transparency.

Using a Lean visual management board is an ideal way to keep your people updated on how the company is progressing. A visual management Lean six sigma approach, or a visual Gantt chart will ensure that projects are kept on track. If your business has not invested in developing an effective visual management system, then you are not managing your people in the most efficient and effective manner.

Why choose Dassault Systèmes for your visual management needs?

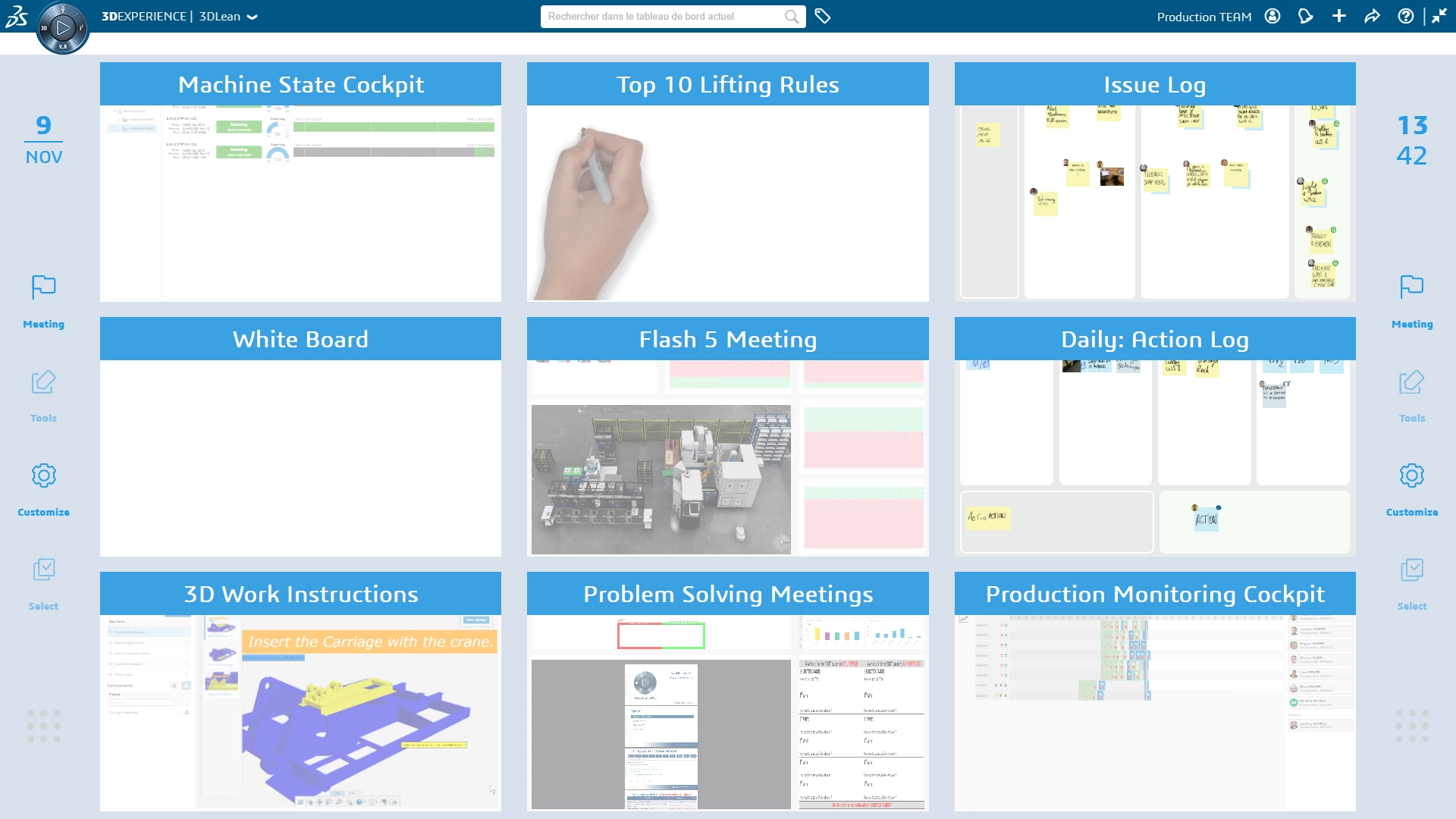

Make Lean management easy with the 3DEXPERIENCE platform

The 3DEXPERIENCE platform is a powerful cloud-based digital environment that allows you access to a range of innovative roles from Dassault Systèmes and lets you share and store files.

The 3DEXPERIENCE platform can be accessed using any device, anywhere in the world, anytime you like. Powered by clusters of data banks linked via the cloud, the platform allows you to access cutting-edge Lean management software like Delmia Lean Team player, Enovia Project Planner, and 3DSwymer without having to invest in expensive IT infrastructure.

Trust a team with proven experience

If you are searching for Lean management software, then we have the solutions you need. Dassault Systèmes can help you to more effectively manage and communicate with your teams. Put your trust in a company that has been renowned for innovation for more than four decades. At Dassault Systèmes, we’ve been providing our customers with exemplary PLM, CAD, and Lean management tools for more than 40 years.