Boost Business Efficiency with Lean Management Principles

The concept of lean management is now practiced by business leaders the world over. In this article, we take a close look at lean management principles and delve into just what makes the lean management system so successful

What is lean management?

The goal of lean management is to arrive at the most effective and efficient method of managing people and work processes. To get a good understanding of lean management, it is important to realize that lean principles are based on three fairly straightforward ideas. The three core lean concepts are:

- Deliver value from the perspective of your customers.

- Strive to eliminate all waste and focus on exceptional quality.

- Ensure that you are always continuously improving work processes.

Lean management is based on the concept that innovative ideas can come from any level of a business’s hierarchy. Rather than focusing on a top-down methodology, lean management focuses on improving how work is done by involving the people who actually complete the tasks.

Having respect for people and continuously striving for excellence are crucial aspects of lean thinking. Using a lean management system, all employees share the responsibility for improving work practices and delivering effective leadership.

Discover the effective Lean management software from Dassault Systèmes

Delmia 3D Lean allows you to eliminate waste, identify issues, and optimize manufacturing processes by using cutting edge Virtual Twin technology. Manufacturing systems, factory floors, and product assemblies can all be digitally replicated to simulate the entire production process.

DELMIA Lean Team Player

Make collaboration effective, intuitive and easy with a cloud-based whiteboard designed to fuel innovation

The principles of lean management

Implementing a lean management system means applying the five main lean principles:

Identify value

Every company wants to create a product that a customer will see value in and be willing to pay for. Companies need to place their focus on identifying their customer’s problems, working to meet their needs, and delivering value added solutions. Anything that does not add value is waste.

Map out the value chain

Value stream mapping involves creating a detailed map of all company workflows. Every action and every staff member that is involved in creating a product needs to be included. In this way, any areas that are not adding value can be identified.

Develop a continuous workflow

All teams need to be operating in the most effective and efficient way possible. Any impediments to achieving optimal efficiency must be identified and removed.

Create a traction system

Also referred to as a pull system, a traction system ensures that tasks are only done if there is demand. A traction system aims to eliminate waste and maximize resource use.

Focus on continuous improvement

A lean management system is not a ‘set it and forget it’ system. A company must strive to always be searching for ways to improve processes. All employees at every level of the hierarchy should be consulted regularly on how they think work processes can be made better.

Browse all the Dassault Systèmes store applications

We feature in our store some of our best software to design, collaborate and innovate throughout the entire product lifecycle.

Content related to lean management

Different types of lean management tools

Various types of lean tools are employed to maximize efficiency and encourage continuous improvement. These tools are used to develop better collaboration between staff and enhance work processes.

- The 5S Principle

- The Kaizen Principle

- The PDCA Cycle

- The Six Sigma Method

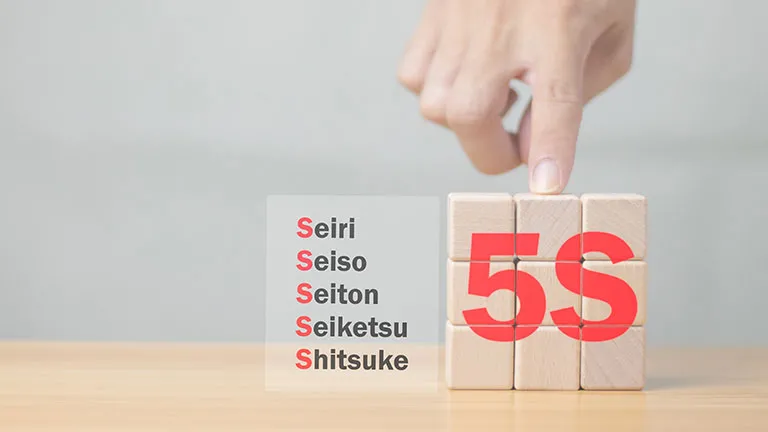

The 5S principle

The 5S principle of lean management is based on five Japanese words that all start with the letter S. it aims to create a safe, clean, uncluttered, and efficient working environment that is free of waste. The 5S principles are:

- Seiri: To organize. Only use the tools that are necessary to complete a task.

- Seiton: Orderliness. Focus on order for good visual management of tools.

- Seiso: Cleanliness. Keep the work areas clean and tidy at all times.

- Seiketsu: Standardize. Develop and implement a regular cleaning schedule.

- Shitsuke: Discipline. Follow the above principles rigorously.

The Kaizen principle

The word Kaizen can be translated as the process of changing for the better. In lean thinking, it is used to designate the concept of continuous improvement. Kaizen lean management focuses on continuously making small, gradual changes to business processes to facilitate improvement over the long term.

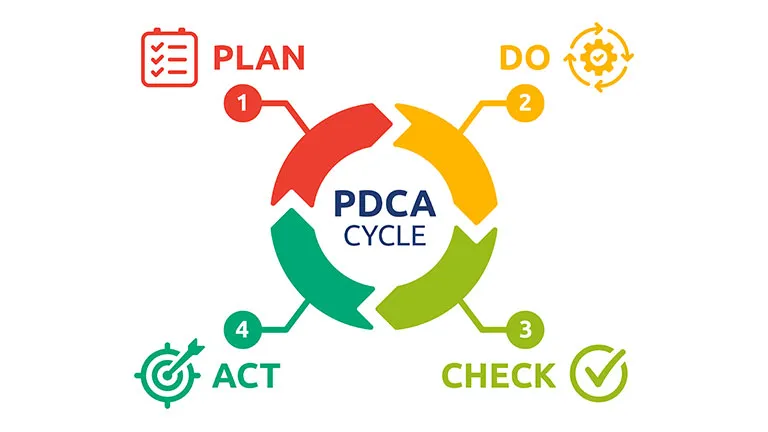

The PDCA cycle

Conceptualized by Walter Shewhart of Bell Laboratories in New York and then further developed by his protégé William Deming. Sometimes referred to as the Deming Wheel or the Deming Cycle, the PDCA cycle is based on the idea that by improving quality a company can reduce costs. PDCA stands for Plan-Do-Check-Act. It is a management method that aims to avoid repeated mistakes and attain the lean principle of continuous improvement.

The six sigma method

The Lean Six Sigma methodology is named after the Greek symbol "σ" which designates "sigma". The Six Sigma method uses data and statistics to locate and eliminate waste and faults in work processes and identify areas of improvement. There are two main methods of implementing the Six Sigma method:

- DMADV: Define, Measure, Analyze, Design, and Validate.

- DMAIC: Define, Measure, Analyze, Improve, and Control

The DMADV phases are used to improve existing production techniques while the DMAIC method is used to improve the products themselves.

What is the difference between lean management and traditional management?

There are significant differences between traditional management techniques and lean management methodologies.

The concept of Gemba

Lean management places a focus on removing hierarchical borders. An example of this is Gemba, which means ‘the real place’. The ‘Gemba walk’ is a technique where senior management regularly visits the factory floor to see how work is being done.

Enhanced respect for people

Under a traditional management system, employees are viewed as costs, whereas lean management views people as assets. Lean management systems use the value stream to organize departments and assign roles. In this way, lean management makes the most of human resources.

Continuous improvement

Traditional management systems are not focused on continuously developing new ways to improve, instead, they concentrate on making minor changes so as not to disturb existing productivity levels. Under a lean system, a problem is seen as an opportunity for improvement. Simply solving the issue is not enough; a better work process must be developed.

Pull systems

A traditional management system will use sales forecasts to develop production strategies. This is known as a ‘push’ method. Lean management focuses on a ‘pull’ method where customer demand is what drives production.

How can you implement lean management in your business?

Making the transition from a traditional management style to a lean based approach requires dedication and effort. Implementing the lean management framework is not an overnight process. It may take some months before a company can have effective lean pull systems in place.

When changing to a lean management style, the first step is to ensure that all employees are kept up to date and are committed to the process. Get advice from experts in the field on how best to prepare your teams. Make use of lean management tools such as dedicated lean management software. Deliberate carefully over any changes, but make sure to implement them rapidly.

Implementing lean principles such as the elimination of waste, maintaining customer focus, and continuous improvement leads to enhanced employee empowerment and reduces bottlenecks and inefficiencies.

The benefits of lean management

Lean management techniques give leadership a better understanding of every aspect of the business. By focusing on respecting all employees, lean techniques create alignment throughout an organization. The act of problem-solving in the Gemba can lead to sustained improvement in both work processes and employee morale.

Lean management also enhances the ability of managers to measure and review performance on both an individual and company-wide level. Companies that implement lean management techniques can use resources in a more efficient manner, which leads to cost reduction and improved productivity.

Explore Dassault Systèmes solutions

Discover the powerful browser-based modeling solutions from Dassault Systèmes. You can design whatever you wish, wherever you are with 3DEXPERIENCE.

Connecting data & people to foster innovation

The 3DEXPERIENCE platform on the cloud gives you access to a various set of applications that allow you to design, simulate, inform and collaborate on a project.

The drawbacks of lean management

There are some disadvantages to implementing a lean management system. Lean management requires a lot of upfront work. For example, the value mapping process can be lengthy and intensive.

Because lean focuses on customer value using pull systems, it is not suitable for all businesses. For instance, production methods based on customer demand can lead to assembly-line bottlenecks and decreased cycle-time if a company is not fully prepared for a sudden spike in orders.

Lean management : Conclusion and perspectives

Lean management systems were first developed and implemented in an industrial sense by the Toyota automotive company in the late 1940s. Since then lean management techniques have been taken up by thousands of diverse companies across the globe. Lean techniques are now one of the leading management styles and are praised for their effectiveness.

Lean management can dramatically enhance the productivity of a company and provide staff with more say in how work processes are developed. It is a style of management that places respect for people at the forefront, both for the employees of the company and the customers it serves. Lean management seeks to remain focused on the customer’s needs while also developing processes that eliminate waste and allow for all members of a company to be involved in problem-solving and process development.

When implementing a lean management system, business leaders can use sophisticated software to streamline the transition process.

Why choose Dassault Systèmes for your Lean management needs?

The 3DEXPERIENCE platform - A better way to work together

Effectively implementing lean management techniques requires reliable communication channels. You can enjoy unrivaled freedom and create and collaborate with your team like never before using the innovative 3DEXPERIENCE platform.

The 3DEXPERIENCE platform is a powerful cloud based solution that allows stakeholders to effectively communicate and securely share and store files in one digital environment.

Delivering innovative software solutions for over 40 years

Managers, leaders, artists, designers, and engineers the world over rely on the powerful software from Dassault Systèmes. From leading automotive and aerospace companies to international manufacturers to famed artists, creative minds in every discipline know that Dassault Systèmes can provide them with the tools they need to shape our world.

A world leader in sustainable innovation, Dassault Systèmes offers users the choice of 11 brands, each one designed to meet specific needs and deliver more functionality, versatility, and power than any other product on the market.