Tosca

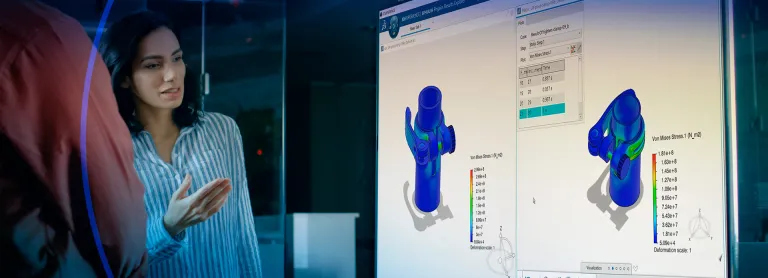

Efficient Optimization Based on FEA and CFD Simulations

Topology and Non-parametric Optimization

The Tosca optimization suite provides dedicated, fast and powerful structural and flow optimization solutions based on finite element analysis (FEA) and computational fluid dynamics (CFD) simulations.

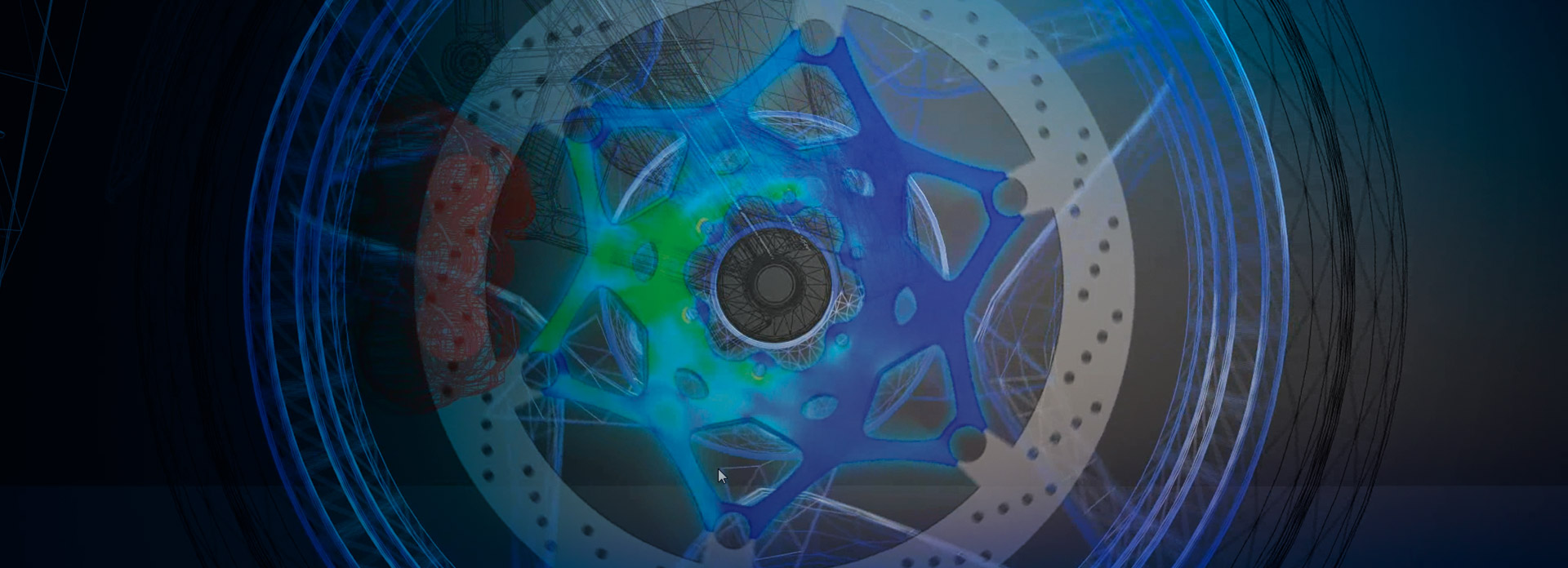

Structure Optimization delivers powerful optimization solutions for the design of lightweight, stiff, and durable parts and assemblies. It shortens development cycles to maximize performance, minimize material and weight, and discover new design possibilities. Tosca Structure offers functionalities for shape, bead, sizing and topology optimization.

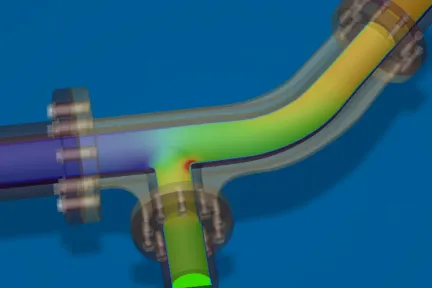

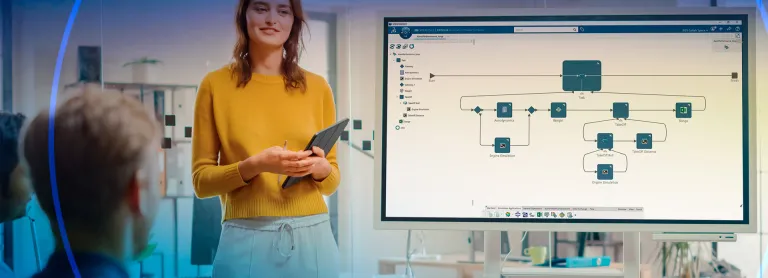

Fluid Optimization enables topology optimization-driven design concepts for fluid flow systems and components. Its capabilities are ideal for automatically creating innovative design ideas for a defined flow task and available package space. Fluid Optimization's unique technology helps you achieve the highest flow performance, quality and eco-efficiency. Engineers must develop innovative products that consider crucial requirements such as lightweight design, safety, comfort, performance, and efficiency to minimize development time.

Advancing Design Concepts and Simulation-Driven Improvements

- Design Concepts in a Virtual Product Development

- Simulation-Driven Design Improvement

- Benefits

Design Concepts in a Virtual Product Development

The early concept phase includes the determination of the product development costs. The automatic generation of optimized design proposals can reduce the number of product development cycles and the number of physical prototypes. It helps elevate product performance and reduce development costs. Starting with the definition of the maximum allowed design space, Tosca Optimization helps you to find the design that fits the design space and considers all product requirements.

Simulation-Driven Design Improvement

Existing designs often only need small changes to improve the overall product performance. Using Tosca Structure’s optimization methods, users can consider relevant product requirements to realize design improvements in a shorter development time.

Topology Optimization Software Benefits

- Accelerate conceptual design, reduce time-to-market

- Support ready-to-manufacture product design

- Save weight and ensure the highest result quality for reliable components

- Avoid error-prone and time-consuming model simplification

- The benefit of realistic simulation and handling nonlinearities directly within the optimization

- Define structural optimization tasks interactively

- It allows users to create fluid flow devices with reduced pressure drop and improve flow uniformity.

Discover the Products

Start Your Journey

The world of Tosca is changing. Discover how to stay a step ahead with SIMULIA.

FAQs About Topology Optimization Software

Topology optimization is a mathematical method used to optimize material layout within a given design space for a given set of loads, boundary conditions, and constraints, with the goal of maximizing the system's performance.

- Density-Based Topology Optimization: This method optimizes the distribution of material within a design domain to achieve the desired structural performance. It assigns varying material densities to different regions of the design space, allowing lower-density areas to be removed or modified to reduce weight while maintaining structural integrity.

- Level-Set-Based Topology Optimization: In this method, the design domain is represented using a level-set function, which defines the boundary between solid and void regions. The optimization process evolves the level-set function to iteratively remove material from non-essential areas while preserving essential structural features, resulting in an optimized design with improved performance and reduced weight.

- Aerospace Components: Optimizing aircraft structural components like wing ribs and engine brackets to reduce weight while maintaining strength.

- Automotive Parts: Enhancing automotive components such as chassis structures and suspension parts for improved fuel efficiency and performance.

- Consumer Products: Improving bicycle frames and sports equipment to enhance durability and performance while reducing material usage.

- Medical Devices: Refining medical implants and surgical instruments to enhance functionality and biocompatibility while minimizing weight.

- Civil Engineering Structures: Streamlining the design of structures such as bridges and buildings to reduce construction costs and environmental impact.

- Electronics Enclosures: Optimizing electronic casings and heat sinks to improve thermal management and reduce weight while maintaining integrity.

- Industrial Machinery: Enhancing machinery components like frames and brackets for improved reliability and efficiency while reducing material usage.

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering