Opera

Electromagnetic and Electromechanical Simulation

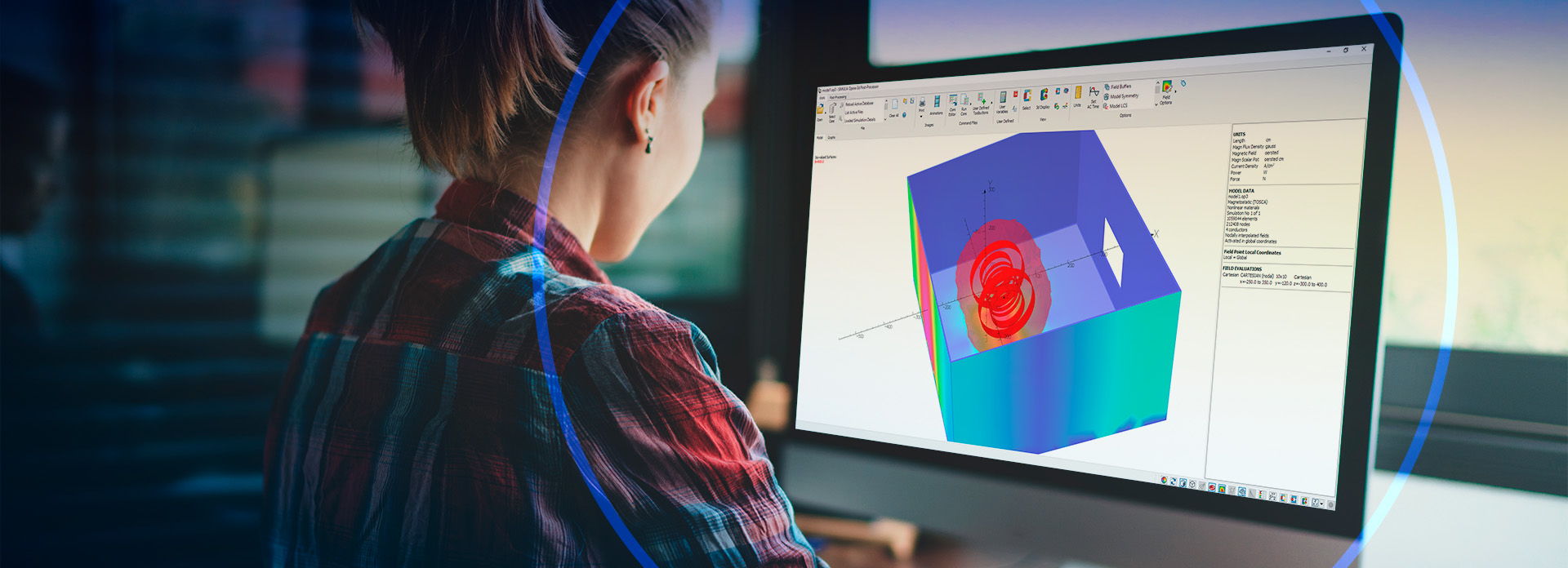

Opera - 3D EM modeling, field simulation and analysis tool

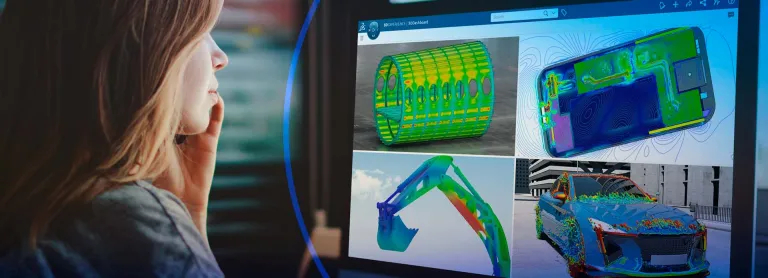

Opera Simulation Software is a Finite Element Analysis software suite that allows engineers to perform simulations of electromagnetic (EM) and electromechanical systems in two and three dimensions. Opera complements the existing SIMULIA EM portfolio with its strength in low-frequency simulation, which is useful for the design of systems such as magnets, electric motors and other electrical machines. Simulation can be used from the earliest stages of development to help bring products to market faster.

Opera includes dedicated 2D and 3D pre- and post-processing environments for problem definition and results analysis. The Graphical User Interface (GUI) gives access to features that simplify electromagnetics and multi-physics design processes. Engineers can accelerate the design process by regularly performing actions into parameterized macro-files.

Why Opera?

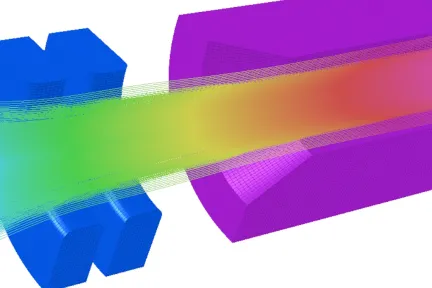

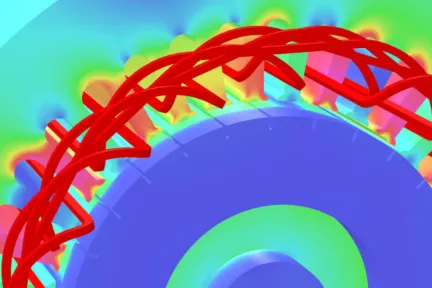

Opera, in adapting to user requirements, has promoted successful usage in the design process for a wide range of applications in different industries. The accuracy Opera provides is of paramount importance when looking at field homogeneities of parts-per-million in medical devices or particle accelerators. Advanced material modeling and solution procedures enable detailed studies of systems containing permanent magnets or superconducting coils. And application-specific front-ends help guide the users through the complex task of simulating and optimizing high-efficiency high-performance motors, generators and transformers.

Opera Product Modules

Opera packaging relies on a core set of modules, including Opera Solutions and Opera Features

Start Your Journey

The world of Design & Simulation is changing. Discover how to stay a step ahead with SIMULIA.

FAQs About Electromagnetic Simulation Software

Numerical simulation of electromagnetic fields is typically based on a discretization of Maxwell's equations in space and time. In the simplest FDTD case, the simulation volume is mapped onto a Cartesian grid. The individual grid cells can be filled with different materials and the electric and magnetic fields are defined along the edges and through the facets of the cells.

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering