University of Southern Queensland

UniSQ researchers use Cleared to Operate and Co-Design to Target solutions to digitally transform composite materials' repair in aircraft.

Transforming Composite Material Repair in Aviation

Over the past 20 years, the advancement of composite materials has delivered huge benefits to the aerospace industry. Composite materials are commonly used in constructing aircraft components because they are stronger, lighter and more durable than metals like aluminum for many components and applications. This improved strength-to-weight ratio can increase the fuel efficiency of an aircraft by around 25% compared to all-metallic constructions.

However, the repair of composite aircraft components is challenging since composite fibers are layered in complex patterns – an issue that doesn’t exist in metallic structures. Meeting this challenge is one of the key areas of focus for the Centre for Future Materials (CFM), a world-leading research center in advanced composite materials and manufacturing, situated at the Toowoomba campus of the University of Southern Queensland (UniSQ) in Australia.

“A repair process is initiated by the identification of damage using non-destructive testing (NDT) during routine inspection and maintenance operations,” said Dr Tristan Shelley, a senior research fellow within CFM. “NDT processes for composite structures usually involve the use of ultrasound testing to assess the internal integrity of the structure. The technical and engineering teams must then carefully remove the damaged section and repair it.”

This process requires technical expertise and can prove incredibly costly to aerospace companies, particularly if it leaves an aircraft out of service. However, the project is striving to make composite repairs faster, more efficient and tailored to the damage site. CFM researchers are collaborating on the project with Dassault Systèmes' Melbourne-based business partner MEMKO and aerospace original equipment manufacturer (OEM) Boeing Australia.

“By relying on Dassault Systèmes’ 3DEXPERIENCE platform, we hope to digitally transform the composite repair process applied to aerospace structures,” Shelley said. “We’re backed by the Australian Government’s iLAuNCH Trailblazer program, which aims to address critical skill gaps and accelerate the development of the country’s space sector. This project is seen as an enabler for both the aerospace and space sectors, where reusability and repair are essential to helping drive down operational costs.”

By linking all the process lifecycle steps, the 3DEXPERIENCE platform could help us create a proof of concept for a complete solution that is expected to be game-changing for the aerospace industry.

Industry-Leading Software for Advanced Composite Repair

Inspired by the software choices of industry leaders, Shelley believes that the applications available on the 3DEXPERIENCE platform provide the most complete solution for the digitization of the composite repair process. He was particularly impressed by the ability to create a digital twin for all stages of aircraft components’ lifecycles.

“While we explored the use of other solutions, there was nothing else available that could provide a continuous thread of data from the initial inspection, to design and manufacturing, ending with the physical repair patch and entry back into service,” Shelley said. “By linking all the process lifecycle steps, the 3DEXPERIENCE platform could help us create a proof of concept for a complete solution that is expected to be game-changing for the aerospace industry.”

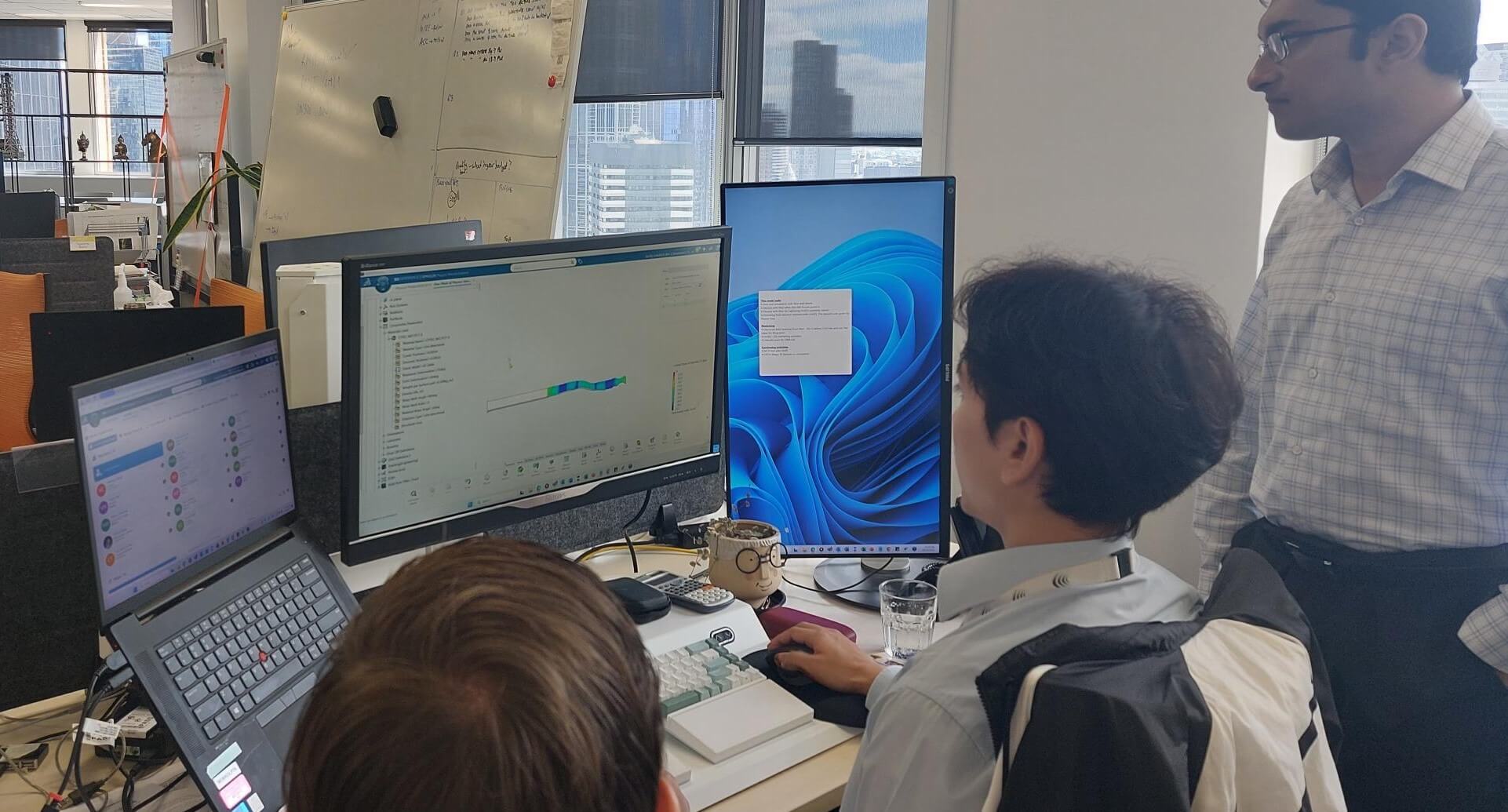

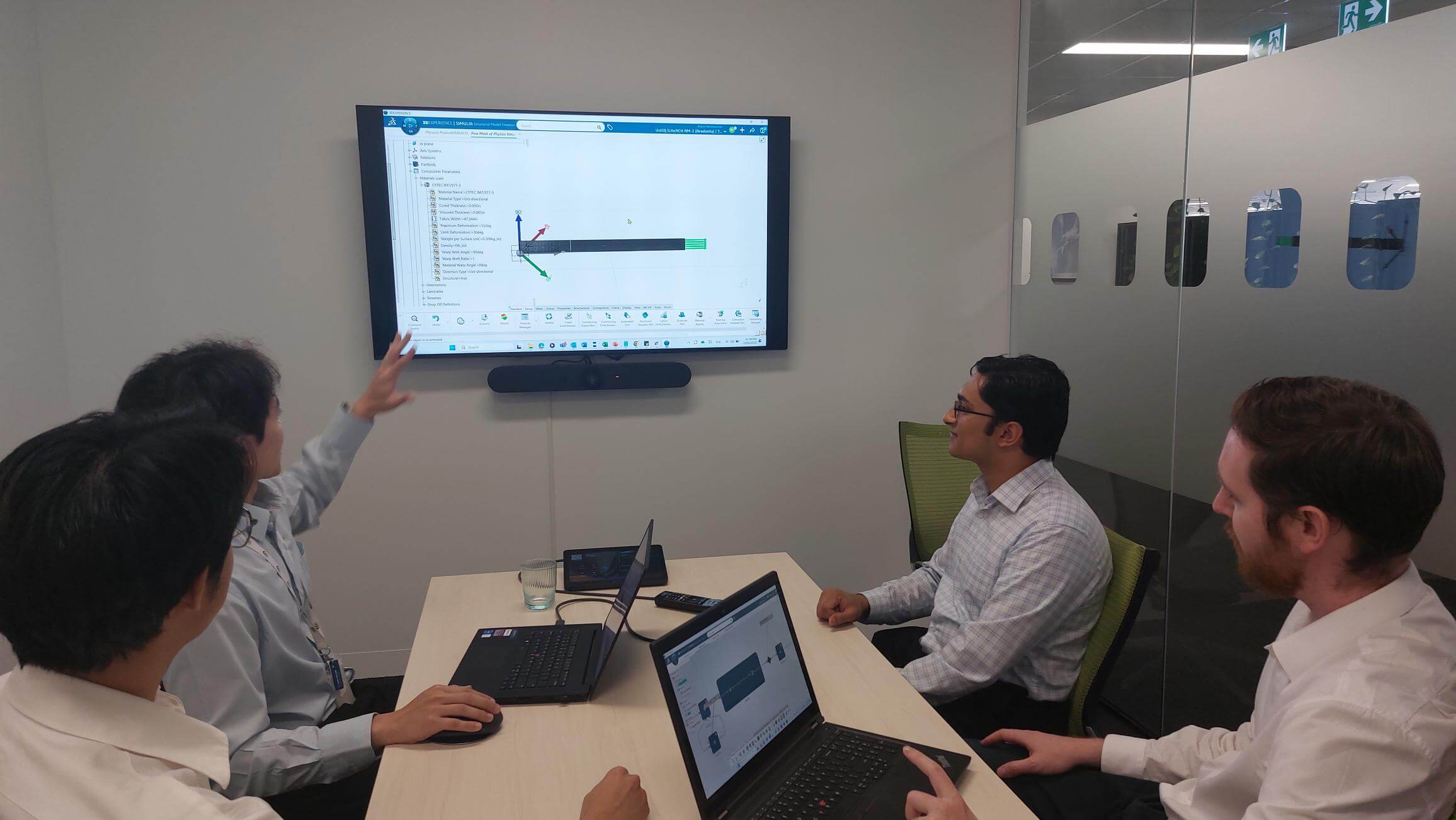

Technical experts from MEMKO are working alongside CFM’s researchers and PhD students to ensure the effective application of Dassault Systèmes solutions to this industry use case. According to Shelley, MEMKO’s role in the implementation has proven invaluable. “Initially, when we started defining the program scope, MEMKO identified the relevant tools that we required,” he said. “To date, that has been incredibly accurate. MEMKO has provided the appropriate servers and helped install software on student and staff workstations. It has also delivered all the necessary training. Overall, we have felt really well-supported.”

Optimizing the Aircraft Composite Repair Process Using Virtual Twins

Students and researchers at CFM have set to work on digitizing the composite repair process within the 3DEXPERIENCE platform, starting with damage detection. “We are refining the NDT process to help engineers identify the repairs area faster and more precisely,” Shelley said. “We use reverse engineering capabilities within the 3DEXPERIENCE platform to read the processed NDT data. This enables the creation of topology (the properties that remain unchanged under continuous deformations) which in turn can be overlaid with actual CAD data. This allows us to analyze and improve the visibility of internal layers to identify the size and extent of the damage.”

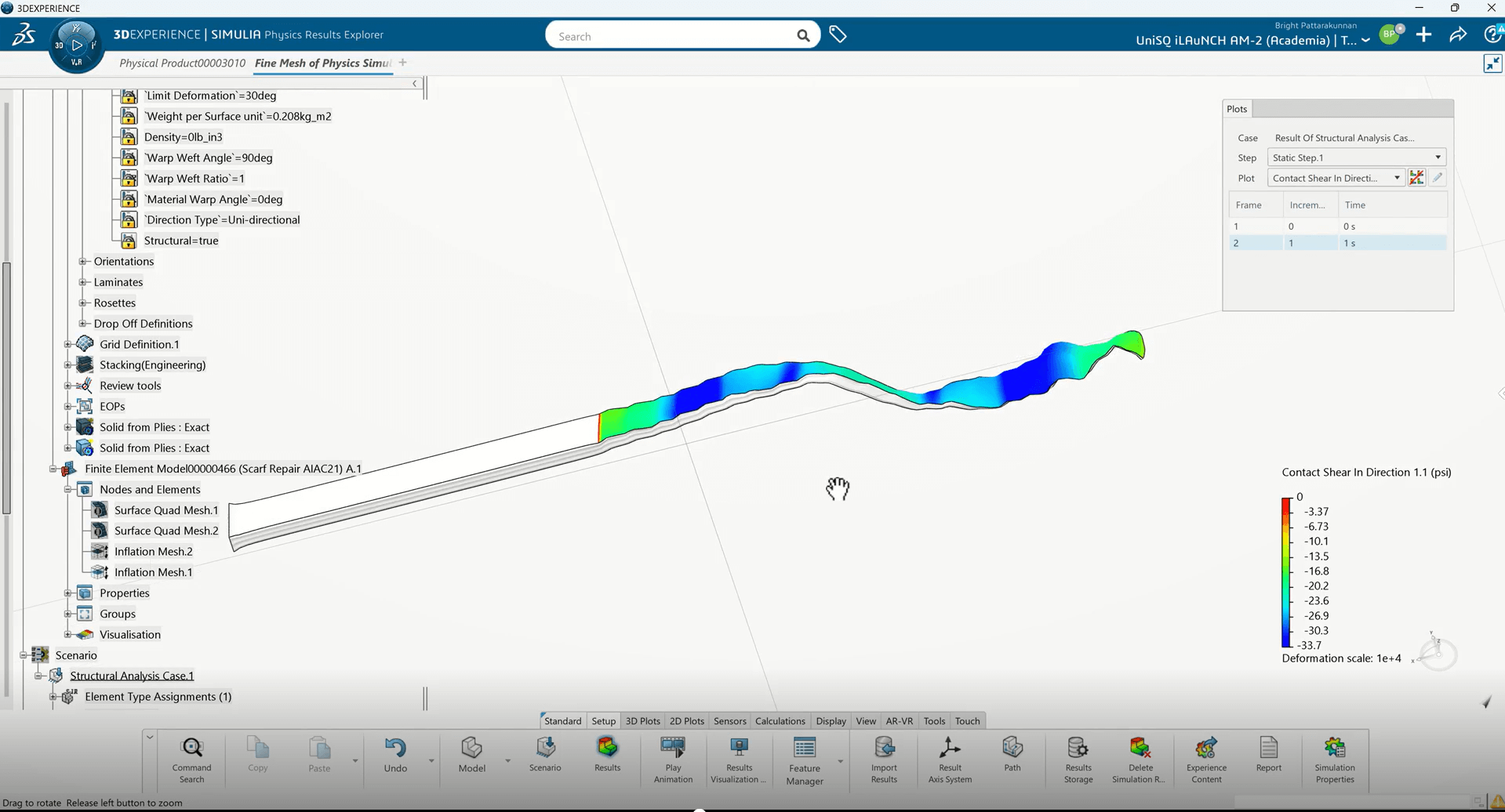

By automating the optimization loop between CATIA and SIMULIA using the 3DEXPERIENCE platform, engineers can explore design outcomes to identify the most effective repair type and geometry. “The aim is to identify the best repair patch shape and thickness as well as the extent of the repair, considering the location and any adjacent structural features,” Shelley said. “Then, using the 3DEXPERIENCE platform, we can define the patch and proceed to implementation of the repair itself. The aim is to remove as little material as possible, yet maintain the part’s original strength to handle the intended design load.”

Maintaining the composite material’s strength requires the original fiber architecture to be restored. This calls for precise fiber placement so that repairs join seamlessly with existing composite structures. To refine this process, which is known as filament winding, Shelley and his team will use the 3DEXPERIENCE platform’s virtual twin capabilities.

“We are capturing real-time visual data from filament winding and feeding this into the virtual twin,” Shelley said. “This allows us to predict and optimize the best wind path and is key to enhancing manufacturing processes and improving the quality of the repair.”

On the 3DEXPERIENCE platform, engineers are able to analyze stress contour plots shown along the scarf repair patch.

Saving Aerospace Leaders Valuable Time and Money

Once the best approach to the repair has been determined, it’s time to replace the damaged section. This traditionally involves manual scarfing – the technique of material subtraction (or machining) on a tapered edge (or a scarf) to create a smooth surface where a new repair patch can be bonded. “The manual scarfing process, which is highly dependent on the technician’s skill, often leads to inconsistencies in the quality of the repair,” said Sai Rohit Behara, a PhD student specializing in quality assurance processes to reduce variability in manufactured parts, using virtual twin models.

To resolve this, Behara uses DELMIA to program scarfing tool paths, with precise instructions for how damaged material should be replaced. “The ability to simulate and refine scarfing tool paths virtually minimizes manual intervention and reduces the risk of inconsistencies on the shop floor,” Behara said. He also uses DELMIA to explore how robots can be programmed to perform scarfing with greater precision.

The virtual workflows we are developing will eliminate both engineering and laborious processes, leading to more efficient and effective maintenance, repair and operations of future fleets.

Connecting the Digital Feedback Loop

3DEXPERIENCE platform tools can then ensure bonding strength between the patch and the parent composite during curing. Sensors are used to track the temperature and strain at the joint – and this data is stored in ENOVIA. “By comparing sensor readings with the digital repair plan, it becomes possible to identify weak bonds or curing inconsistencies,” Behara said. “We enter these findings into CATIA and DELMIA to further optimize the repair.”

While each Dassault Systèmes tool is useful independently, their combined capabilities on the 3DEXPERIENCE platform are key to the project’s success. “CATIA and SIMULIA enable simultaneous modeling and simulation, or MODSIM,” said Vishnu Nair, another of CFM’s PhD students. “Meanwhile, in the repair workflow, DELMIA helps engineers to understand the challenges that might arise when attempting to translate the design from the virtual world to the real world. ENOVIA maintains a continuous data repository of all the design changes that have been trialed in past efforts. The combination of these technologies is critical for managing highly regulated repair processes.”

Ultimately, by virtually simulating the manufacturing and repair of composite components, Dassault Systèmes’ solutions enable crucial operations in the aerospace value chain to be shorter and more accurate. “The virtual workflows we are developing will eliminate both engineering and laborious processes, leading to more efficient and effective maintenance, repair and operations of future fleets,” Shelley said.

A Platform to Teach Industry-Ready Skills

As well as improving industry processes, CFM’s decision to adopt Dassault Systèmes technologies will equip students with the skills they need as they enter the workforce.

“When I started learning DELMIA for robot simulation, everything became more interactive,” Behara said. “Instead of dealing with complex calculations, I could visualize and validate the robot’s motion in a graphical environment, making automation much easier to understand.”

PhD student Ryan Stickland is also getting a lot from the software. Using the Dassault Systèmes solutions, he has built a foundational understanding of several digital skills like aircraft composite simulation and finite element methods and can unlock value from the digital thread. “Additionally, I am building knowledge in fields like stakeholder collaboration and data management,” he said. “These, along with knowledge gained about prevalent industry practices, will all prove useful for my subsequent professional future within the aerospace sector.”

Over the next 12 months, CFM will leverage 3DEXPERIENCE for Education's solutions to support its workforce development and upskilling programs that aim to address critical skills shortages within the growing aerospace industry and to support Australia’s sovereign capability in this area. It also is exploring how it can build on its relationship with MEMKO and Dassault Systèmes on future projects to solve complex industry challenges in the aerospace sector.

“This is just the start of what we will do together,” Shelley said. “We’re already discussing future endeavors, and we look forward to working continuously towards providing relevant and fit-for-purpose innovations that will help transform the future of the aerospace industry.”

Discover more about the Keep Them Operating industry solution experience.

Discover more about the Cleared to Operate industry solution experience.

More about iLAuNCH Trailblazer

The Innovative Launch, Automation, Novel Materials, Communications, and Hypersonics Hub (iLAuNCH) Trailblazer is a US$50 million grant funded program (matched by both the University and Industry partners). It aims to build Australia’s enduring space capability through the commercialization of projects, a fast-track accelerator and skills development to build the workforce of the future. Funded by the Australian Government’s Department of Education, this collaborative program is led by the University of Southern Queensland (UniSQ) in collaboration with The Australian National University and the University of South Australia in addition to more than 20 industry partners, including MEMKO and Boeing Australia.

The program described in this article is the largest within the iLAuNCH Trailblazer, employing at least three full-time researchers, and four Master’s and PhD students. The program is also enabling the advancement of the Centre for Future Materials (CFM) capabilities in industrial scale filament winding and automated fibre placement, through upgrades to existing manufacturing cells.

Focus on Centre for Future Materials

CFM is an industry-focused research center within the Research and Innovation Division at the University of Southern Queensland (UniSQ). Heavily focused on composite materials, it boasts one of the country’s largest dedicated composite materials manufacturing and testing facilities, including multiple manufacturing cells of an industrial scale and world-class machinery unique to Australia’s research and development communities (in both academia and industry). CFM also carries out research into sustainable initiatives for industry (recycling and clean energy), advanced composites manufacturing, a significant focus on civil composites, and functional materials such as thermoelectrics and fire retardancy.

For more information: https://www.unisq.edu.au/research/institutes-centres/iaess/centre-for-future-materials

Focus on MEMKO

Melbourne-based digital engineering company MEMKO offers industry-specific products, technology, training and engineering solutions to assist and support customers in advanced and highly regulated industries such as aerospace. Its employees have extensive engineering, quality, manufacturing and management capabilities and provide support in the form of engineering and technology services, continued engineering, regulatory and technical training, regulatory approvals and organizational audits, strategic planning, market research and business development, mentoring, development and recruitment of management and engineering staff.

For more information: https://memko.com.au/