Deutsche Aircraft

From immersive sales experiences to streamlined certification, Deutsche Aircraft uses Dassault Systèmes' virtual twin to bring its next-generation regional aviation to life.

(Photo © Deutsche Aircraft)

Certification is the ultimate goal and, with Dassault Systèmes, we’re using modern processes and solutions to make that as efficient as possible.

Virtual twin helps define the future of regional flight

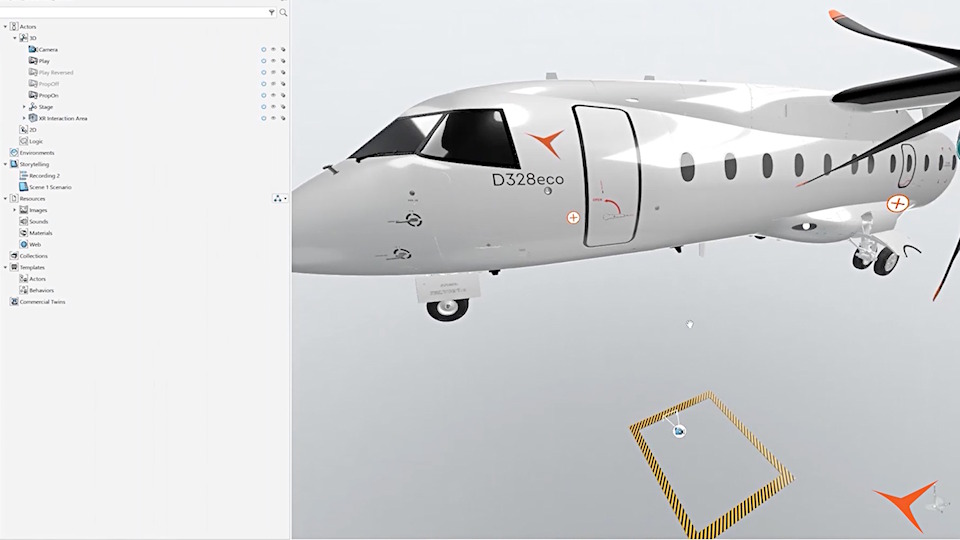

An airline executive puts on an Apple Vision Pro headset and is instantly transported into the future of regional flight. They’re considering options to expand their fleet, and this is their first glimpse of how Deutsche Aircraft’s D328eco® next-generation turboprop is taking shape. Moving through the virtual cabin, they see everything in vivid detail, from seating and lighting to overhead storage and aisle space. Beyond the interior, the experience shifts to the factory floor, where they visualize how the aircraft will come together during final assembly.

The D328eco® builds on the proven design of the Dornier 328 aircraft. Featuring modern avionics, improved performance and compatibility with sustainable aviation fuel (SAF), the aircraft will achieve lower emissions without compromising on range or reliability. Its flexible design and fuel efficiency make it an ideal choice for connecting short- and medium-haul routes across both mature and emerging markets.

“Our vision is to bring a new product to regional aviation,” said Nico Neumann, CEO of Deutsche Aircraft. “We’re building on the DNA of the D328® and incorporating new technologies that will revolutionize the market. It’s a fuel-efficient aircraft that delivers jet-level comfort in the turboprop segment.”

Digital innovation is at the heart of this vision. By developing the D328eco® on Dassault Systèmes’ 3DEXPERIENCE platform, Deutsche Aircraft is accelerating every stage of the journey, from design and testing to certification and production.

A regional aircraft built to be flexible and sustainable

The D328eco® is designed for flexibility, from its configuration options down to its performance capabilities. It can operate in hot and high-altitude conditions, take off and land on short runways, and adapt to a range of mission profiles, including cargo, medical evacuation and humanitarian relief. This versatility makes it well suited to address growing demand in underserved regions, where reliable air travel is a game changer.

“There’s huge demand for fleet replacements but also tremendous growth in markets like India,” Neumann said. “While the major hubs are well connected, many regions still aren’t. Our product addresses that gap by offering flexibility, low cost and high reliability.”

Sustainability is another key priority for Deutsche Aircraft. The company is committed to embedding sustainable principles across all aspects of the product development lifecycle rather than treating it as a separate box to check. Indeed, the company sees sustainability as a natural outcome of more intelligent and efficient engineering.

“Sustainability comes from doing things smarter,” Neumann said. “When you reduce fuel consumption and improve efficiency across certification and production, you’re also reducing waste, effort and emissions. It’s all connected.”

The company’s close partnership with Dassault Systèmes helps enable that mindset. “It’s very collaborative,” Neumann added. “We have fast, open communication and we’re collaborating on some innovation projects and testing new capabilities. This is possible because, as a smaller company, we’re agile and can move quickly.”

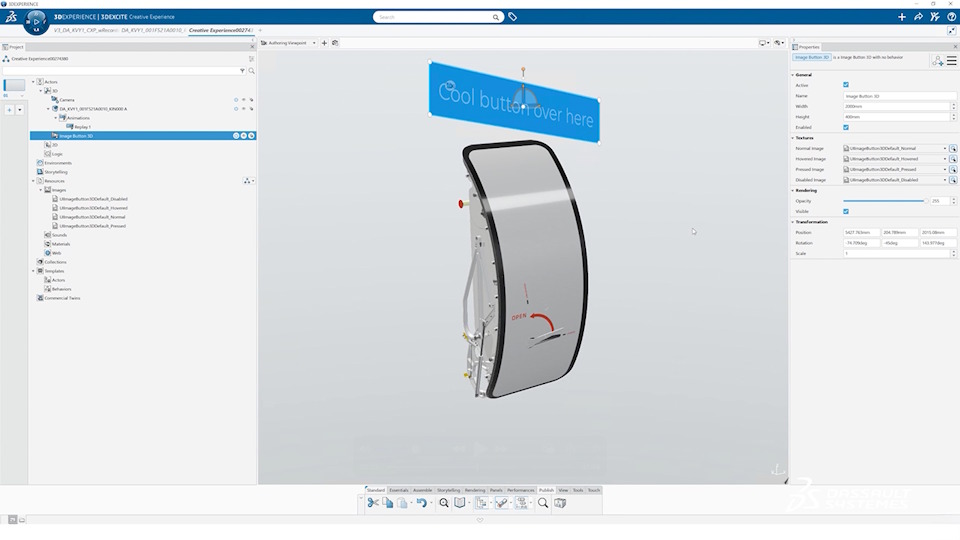

Using the 3DEXPERIENCE platform, Deutsche Aircraft explores and designs every detail of the D328eco®—including cabin layouts and door operations.

Virtual twin supports flight testing

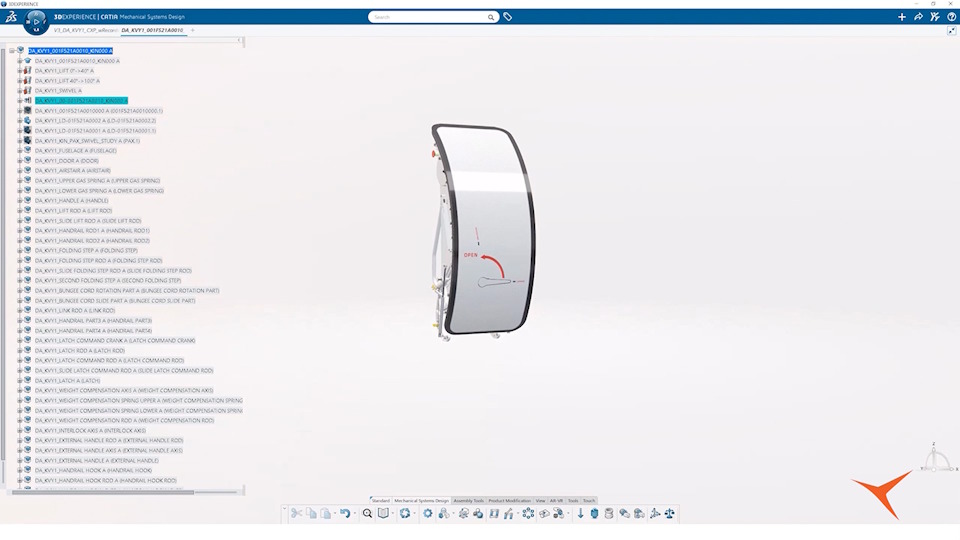

A major advantage of Deutsche Aircraft’s digital-first approach is the ability to simulate aircraft behavior well before physical production begins. The shift from traditional 2D drawings to immersive 3D modeling in CATIA, all managed within the platform’s virtual twin environment, has transformed how the team approaches engineering and flight testing.

“Our engineers and test pilots are already flying the aircraft virtually,” Neumann said. “The virtual twin helps us carry out testing on the ground and reduce risk in our flight test campaigns.”

Inside a fully operational engineering flight simulator, the team evaluates every aspect of the D328eco®’s performance. These simulations are connected to the virtual twin, creating a continuous feedback loop. Design decisions, test results and operational insights are all captured and compared, refining the aircraft in real time. The company is also onboarding its suppliers to the 3DEXPERIENCE platform as part of its plans to create a collaborative working environment and fully connected information flow across the value chain.

“We see streamlined, digitalized data as the currency of tomorrow,” Neumann said. “By applying the virtual twin across the lifecycle, we can improve reliability and help operators lower their costs, which is what ultimately matters.”

We see streamlined, digitalized data as the currency of tomorrow. By applying the virtual twin across the lifecycle, we can improve reliability and help operators lower their costs, which is what ultimately matters.

From certification to aftermarket in one environment

Beyond engineering and testing, the 3DEXPERIENCE platform supports almost every facet of the aircraft program. Certification data, training modules, customer demos and even factory layout planning all happen within the shared virtual environment.

“Certification is the ultimate goal and, with Dassault Systèmes, we’re using modern processes and solutions to make that as efficient as possible,” Neumann explained. “Our certification program is running under EASA’s product change rules. We already have a type certificate, which we’re modifying with the new models.”

The 3DEXPERIENCE platform is widely used in advanced air mobility to certify the next generation of aircraft. Dassault Systèmes’ expertise adds value by connecting OEMs with regulation authorities.

ENOVIA plays a central role in managing product data, engineering changes and traceability throughout the certification process. It makes sure that every design decision, requirement and update is documented and accessible, streamlining collaboration across teams and regulators alike. That same digital backbone supports planning for aftermarket services. By capturing every detail in one system, Deutsche Aircraft can tailor support for operators, particularly smaller ones, who need high reliability and clear maintenance processes without unnecessary complexity.

“What we need from the virtual twin is the ability to support both certification and aftermarket at the same time,” Neumann said. “It’s really impressive what’s possible. We can use the virtual twin to support customers, deliver training and capture certification requirements for the authorities.”

The D328eco®: Deutsche Aircraft’s next-generation turboprop, delivering lower emissions, modern comfort, and efficiency for regional routes.

(Photos © Deutsche Aircraft)

Immersive sales and supplier experiences

Building on this digital continuity, Deutsche Aircraft extends the power of the virtual twin to its sales and marketing team, as well as suppliers. Connected to the 3DEXPERIENCE platform’s 3DLive app, the Apple Vision Pro headset projects full-scale, scientifically accurate virtual twins directly into the user’s environment.

Engineers, suppliers and prospective customers can all step into the fully interactive, spatial computing experience and explore the D328eco® cabin, observe complex system interactions and visualize the aircraft’s assembly. Crews benefit from intuitive, process-integrated training to learn critical procedures in a safe, repeatable and immersive way thanks to 3DLive on the Apple Vision Pro. This experience is the result of a partnership between Apple and Dassault Systèmes and powered by the same virtual twin technology Deutsche Aircraft uses to design, test, certify and build its aircraft.

“Our customers and suppliers can explore not just the aircraft but also how the final assembly line is set up,” Neumann said. “It gives them a detailed impression of how everything will work based on real data.”

The immersive environment supports collaborative planning across the value chain, accelerates design validation and streamlines communication. Whether it’s a supplier confirming installation tolerances, maintenance crews running through procedures, or potential customers reviewing cabin configurations, everyone shares the same detailed, up-to-date information within an integrated workflow.

“In places like India, manufacturers need 3D data,” Neumann said. “This gives us a speed advantage. We can show training concepts, simulate maintenance and present everything clearly in one experience.”

Our engineers and test pilots are already flying the aircraft virtually. The virtual twin helps us carry out testing on the ground and reduce risk in our flight test campaigns.

A leading name in regional aviation

Deutsche Aircraft is now moving from virtual development to real-world execution. As the D328eco® moves closer to the production phase, Deutsche Aircraft uses DELMIA to virtually engineer and simulate its carbon-neutral assembly line in Leipzig. By generating a virtual twin of the manufacturing facility, the team can plan every detail, from plant layout and resource allocation to materials flow and work instructions.

Soon, the company will begin its first flight testing campaign. Every result will feed back into the virtual twin, using SIMULIA to close the loop between virtual simulations and real data. It’s a critical step on the path to commercial operation and a milestone that reflects the company’s steady momentum and commitment to a more sustainable future for regional aviation.

“We’re transitioning from a digital aircraft to physical production,” said Neumann. “All the data we collect feeds directly back into the virtual twin, allowing us to continuously compare virtual test results with real flight test outcomes. Our approach is based on continuous learning and refinement.”

Dassault Systèmes is recognized in the advanced air mobility sector as an ecosystem player, combining mature, proven solutions with emerging technologies like sense computing, part of the 3D UNIV+RSES generation. For Deutsche Aircraft, this partnership is central to executing its digital-first strategy. As the D328eco® program ramps up, Neumann is excited about how Deutsche Aircraft is redefining regional aviation and connecting more people and places around the world. “Deutsche Aircraft will be recognized as the regional OEM from Germany, known for excellence,” he said.

Focus on Deutsche Aircraft

Deutsche Aircraft is a German aircraft manufacturer built on the heritage of aircraft pioneers and Dornier’s reputation for design, quality and innovative aircraft solution. Propelled by the urgency to reduce fuel consumption, carbon emissions and our impact on the planet, far in advance of ambitious international net zero targets, the company is accelerating the aviation industry’s transition towards carbon neutrality.

For more information: http://deutscheaircraft.com