How Mechanical Design Shapes the Modern World

Mechanical design shapes our world and transforms our lives. It is integral to the development of infrastructure, technology, and mobility. Mechanical design allows organizations and companies to foster innovation, solve complex problems, and produce precision machinery.

Mechanical design is a crucial aspect of the machine development process. Engineers and designers use mechanical design techniques to produce a variety of machinery and products that we use every day. From the furniture in our homes and offices to the vehicles we drive, the buildings we live and work in, and the technology that we rely on - it all starts with the mechanical design process.

What is mechanical design?

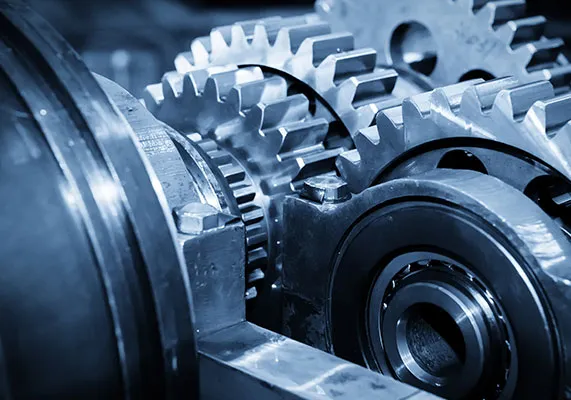

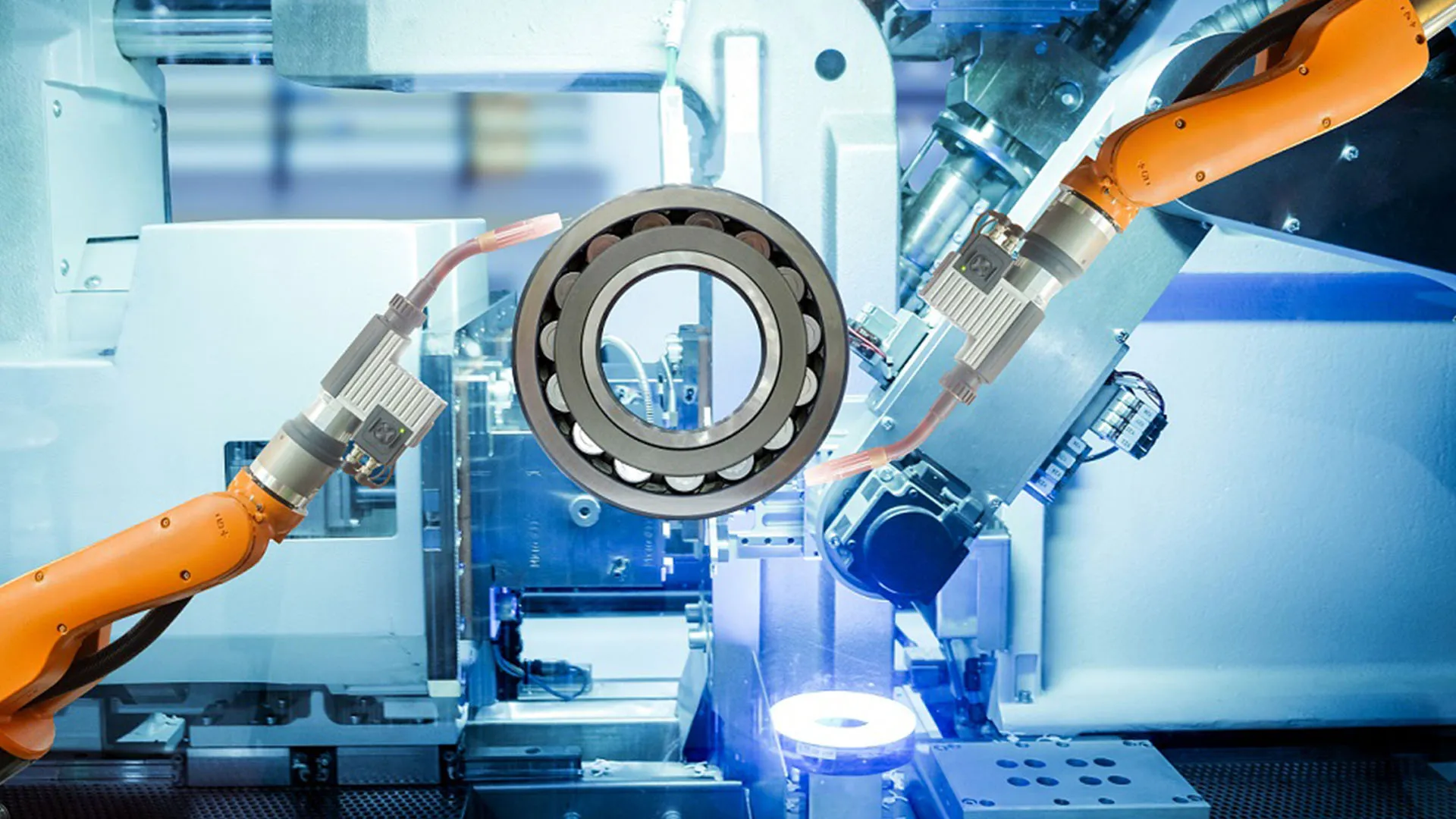

Often referred to as engineering design or machine design, mechanical design is the process of designing components, parts, products, and systems that are inherently mechanical in nature. Any type of machinery or any product that has complex parts requires some form of mechanical design. Mechanical design techniques are used to produce objects such as gears, clutches, shafts, and fasteners.

Engineers who focus on mechanical design are concerned with how various mechanical parts react with each other and their environment. The main aim of the mechanical design process is to produce the most efficient, reliable, and cost-effective method of creating a mechanical system. Mechanical design can be used to create an entirely new product or machine, or it can be used to enhance the features of an existing product or machine.

Discover Dassault Systèmes mechanical design solutions

The 3DEXPERIENCE store gives designers access to a range of industry-leading CAD software from Dassault Systèmes. These highly intuitive applications work in conjunction with the 3DEXPERIENCE cloud platform. Creators can trade ideas, share work, and inspire one another in real-time using a single completed connected ecosystem.

What is the difference between mechanical design and mechanical engineering?

- Mechanical Engineering

- Mechanical Design

Mechanical engineering

Mechanical engineering refers to the practice of producing a machine concept and bringing it to reality by physically being involved in the product-development process.

Typical Duties of a Mechanical Engineer

A mechanical engineer designs, builds, and repairs machinery and products. The first stages of a machine or a product will be based on the basic designs created by the mechanical engineer. Mechanical engineers use mathematics and physics to produce functional and feasible design concepts. A mechanical engineer is typically involved in managing the process of designing and manufacturing machinery, products, or equipment.

Mechanical design

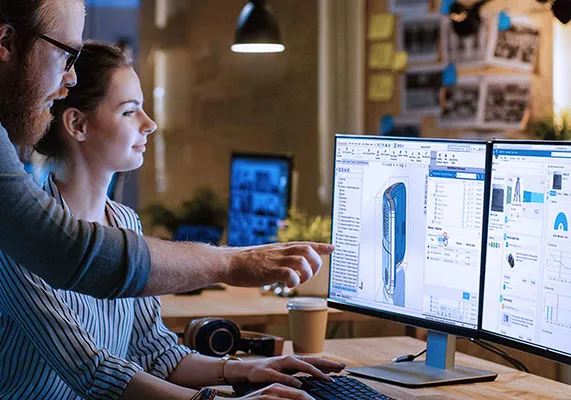

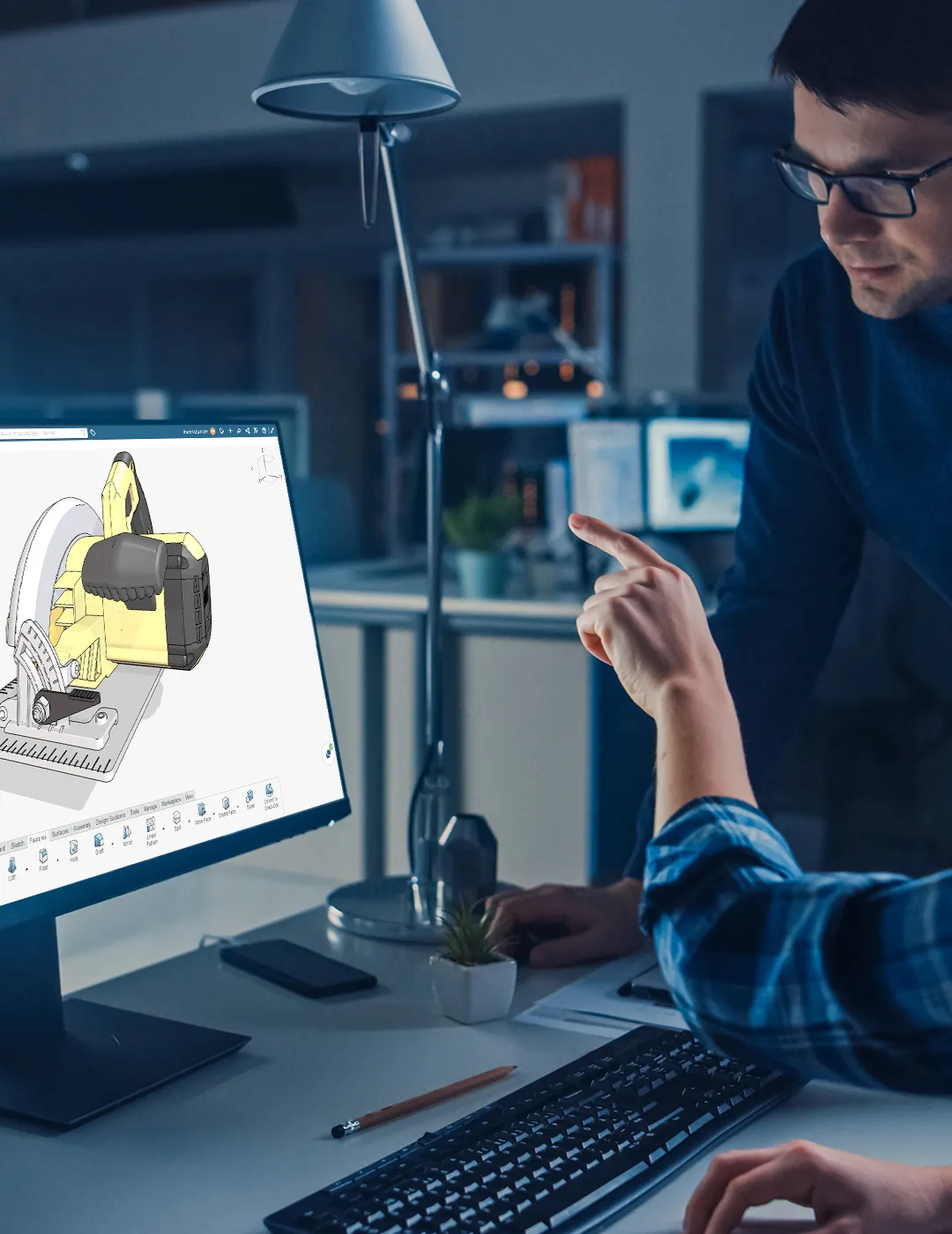

Mechanical design refers to the practice of refining initial concepts and testing using CAD software to create two- or three-dimensional models.

Typical Duties of a Mechanical Designer

A mechanical designer refines the initial concept produced by the mechanical engineer. This is done by using CAD programs to create two- or three-dimensional models. These models are then used to test different components and materials or simulate how an object reacts to real-world environments.

Mechanical designers are usually in constant contact with other stakeholders during the design process. Mechanical designers use their skills to develop innovative ways of creating new products or redevelop existing products. They ensure that the design of a machine or product is optimal, resource-efficient, and realistic.

Why is mechanical design important?

Mechanical design plays an integral role in the development process of a product. While the initial designs created by the mechanical engineer form the basis of a machine, they may not be the most efficient or cost-effective way of bringing the product into reality.

The mechanical design process enables companies to develop machinery, parts, or products that perform as expected, are reliable and durable and can be manufactured with less waste. The process of mechanical design results in the development of higher-quality products and systems.

Using specialized CAD mechanical engineering software, a mechanical design engineer can test different combinations of components or materials, apply real-world stress tests to products, and change designs without the need to constantly produce physical prototypes. Time-to-market is reduced, error and fault rates are diminished, and development costs are greatly decreased.

Browse all the Dassault Systèmes store applications

We feature in our store some of our best software to design, collaborate and innovate throughout the entire product lifecycle.

Content Related to Mechanical Design

What is the mechanical design process?

By following an optimized mechanical design process, engineers and designers can develop more innovative, sustainable, and environmentally friendly systems, products, and machinery.

The mechanical design process is not the same as the scientific method. It does not involve testing hypotheses with experiments or making observations on the outcomes. Instead, the mechanical design process is concerned with designing, building, and then testing a product or machine that solves a specific problem.

Key considerations in mechanical design

There are a number of considerations that must be kept in mind during the mechanical design process. Certain factors must be weighed up and their impact on the overall design assessed. This is true whether a mechanical design engineer is involved in developing a particular component, a complete mechanical system, or a stand-alone product.

During the mechanical design process, the key considerations are:

Functionality

The product or machinery must be functional and reliable at all times. It must operate consistently and perform its intended function as expected, without any issues or malfunctions. This is essential for the product or machinery to be effective and useful for the intended purpose.

Safety

The product or machinery must be safe to use or perform its functions safely. When in use, it must not endanger the operator or any persons in its vicinity. The product or machinery must conform to all relevant safety standards.

Cost

The total cost of producing the component or product needs to be considered. The optimal mechanical design will deliver the highest levels of safety and functionality for the lowest overall cost.

Manufacturability

The product or machine should be able to be assembled quickly. All elements should be designed with unit assembly production lines in mind. In addition to assembly, the elements of the machine or product should also be designed for quick disassembly to aid repair, maintenance, or transport.

Strength Criteria

All components and other elements of the machine or product should be strong enough to withstand both operational stresses and environmental forces. The product or machine should be designed to be durable. It should be able to reach its full lifespan without deforming or sustaining permanent damage.

Material Selection

The choice of materials used to make the machine or product greatly impacts other considerations, such as cost, manufacturability, and strength. Mechanical design allows for the use of lightweight materials that are durable and sustainable.

Material Reduction

Reducing the amount of material used in the production process can lower costs, speed up time-to-market, and reduce environmental impact. Mechanical system design using 3D CAD technology will enable designers to test different ways of assembling a machine or product using fewer materials. CAD software also helps to reduce material use in the design stages by eliminating the need for multiple physical prototypes to be built.

Kinematics of Mechanisms

The movement of all mechanisms within the machine or product should be fluid and without stiffness or rigidity. Where required, lubrication may be necessary to avoid wear on components. The kinematics of the mechanisms should not cause undue damage to themselves or the product or machine itself over time.

Total Optimization

The machine or product should be optimized in such a way that all the above considerations are accounted for. No one factor should impede the functionality or efficiency of another. For example, choosing a more lightweight material may increase costs or decrease strength.

Explore Dassault Systèmes solutions

Discover the powerful browser-based modeling solutions from Dassault Systèmes. You can design whatever you wish, wherever you are with 3DEXPERIENCE.

Connecting data & people to foster innovation

The 3DEXPERIENCE platform on the cloud gives you access to a various set of applications that allow you to design, simulate, inform and collaborate on a project.

What are the tools used by mechanical designers?

The first instances of mechanical design began with one person using a pen and paper to sketch out and refine a concept. This method meant that the drawing of mechanical engineering designs was laborious and prone to errors.

Modern technology has enabled the development of highly sophisticated software tools that optimize the process of mechanical drafting and design. A mechanical drafter can use powerful CAD software to render lifelike 3D models. These models can then be used with FEA software (Finite Element Analysis software), computer-aided engineering (CAE) tools and coding software to test how a design will react to stress, vibration, heat, motion, and environmental conditions.

These tools allow designers to create and manipulate 3D models of mechanical components and systems, analyze their structural integrity and performance, and generate technical drawings and documentation. Other tools that may be used by mechanical designers include prototyping equipment, manufacturing software, and project management software.

Why choose Dassault Systèmes for your mechanical design needs ?

Industry-specific solutions and strong customer support

Dassault Systèmes' software is used by many leading manufacturers in various industries, and the company offers industry-specific solutions tailored to the needs of different sectors, such as aerospace, automotive, and consumer goods.

Dassault Systèmes has a large and experienced customer support team that can provide training, technical assistance, and other resources to help designers get the most out of their software.

The power of the 3DEXPERIENCE

The 3DEXPERIENCE Platform accelerates the pace of product innovation by enabling multi-disciplinary teams to collaborate in real-time on a single online platform. All skill levels can use Dassault Systèmes CAD tools to generate complex geometries and explore patterns and solutions with generative design.

The 3DEXPERIENCE store provides you with immediate access to our apps without the need to install or configure any type of software. You can access the Dassault Systèmes CAD apps from any web browser and on any device.