What is generative design?

Generative design is a revolutionary engineering methodology that harnesses the power of artificial intelligence (AI) and cloud computing. Keep reading to learn the principles of generative design and find out how generative design is changing the way we design products.

What is generative design?

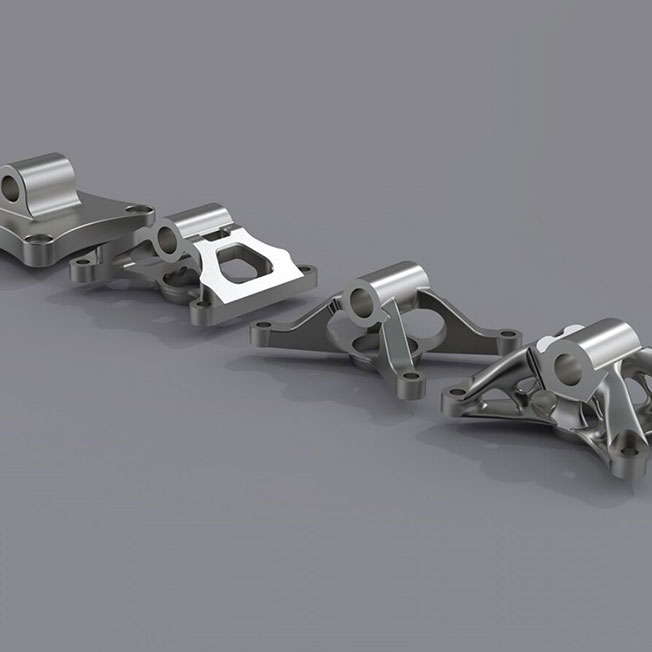

Generative design is an iterative engineering process that produces optimized 3D models using AI software and cloud computing. An engineer or designer inputs a series of design requirements and parameters into specialized generative design software. The software then automatically creates a range of designs based on the pre-defined constraints and needs of the user.

Some experts have said that generative design can be likened to the evolutionary process of nature, except that it happens on a much faster scale. The development of generative design represents a significant milestone in CAD and CAE technology.

Whether you're a mechanical engineer or a draftsman, understanding and utilizing generative design can greatly enhance your design process and outcomes.

Discover the generative design solutions from Dassault Systèmes

Create highly complex design iterations quickly and easily using the innovative generative shape design software from Dassault Systèmes. You can get immediate access to exceptional generative design tools such as CATIA Mechanical Designer and CATIA Sheet Metal Designer via the Dassault Systèmes store.

SOLIDWORKS Design

From mechanical 2D or 3D design to manufacturing, accelerate your processes at an affordable price.

How does generative design work?

While there are various generative design methods, in essence, generative design produces iterations of 3D models from one or multiple pieces of software based on an engineer’s input.

An engineer first inputs constraints and limits for the desired output and details the forces, pressures, and loads the product must be able to withstand. The engineer also inputs details about the materials that will be used to create the product and information about the manufacturing process, whether it is a computer numerical control (CNC) process or use 3D printing, and so on.

The more variables and information the user provides the software with, the more designs the AI can come up with. More information also means that the AI will be able to produce better, more highly optimized designs. A state-of-the-art generative design tool can produce thousands of designs in a very short amount of time, especially if it also uses the power of cloud computing.

It is important to note that generative design does not replace the role of the engineer or designer. Rather, it is a tool that is used to enhance and speed up the design process. Generative design software only works if it has high-quality data that it can use to create designs. Once the designs have been generated by the AI software, then the engineer or designer must then choose the one that best suits their purposes.

How does generative design differ from traditional design methods?

It is clear that generative design methods are a dramatic departure from traditional design methods. Using traditional design methodology, an engineer would create a 2D sketch of a product which would then be passed onto a designer to create a 3D model using CAD software. The 3D model would then be sent back to the engineer to test and refine.

You could say that generative design reverses the traditional process. Instead of beginning with the engineer’s design concept, it starts with an engineer inputting the constraints and requirements and then uses AI software to create multiple iterations of a 3D model.

What are the benefits of generative design?

There are many benefits to using generative design. The speed at which AI can develop design iterations can drastically shorten the entire product development process. Since generative design software works to provide a huge number of optimized designs, engineers can select the best variations to develop high-performing products. Faster iterations also result in faster time to market. Generative design also removes the risk of human error and helps engineers to avoid spending large amounts of time on tedious and repetitious iteration work.

Using algorithm-powered design proposals cuts down on costs as it automates the simulation and prototype testing process and eliminates the need for involved computer-aided engineering (CAE) analysis.

Another huge benefit of generative design is that it allows for more innovative designs. AI eliminates self-imposed restraints caused by preconceived biases from previous projects and can produce designs that are often highly creative.

What are the disadvantages of generative design?

While there are significant benefits to using generative design processes, it must be said that there are also drawbacks and limitations. The generative design method operates using the computer programmer concept of Garbage In Garbage Out (GIGO), which basically means that generative design gives results based on the data it receives. AI software can only produce quality designs if it has quality information from an experienced engineer.

The complexity of the algorithms used in generative design software often makes the design process a black box. While engineers can input parameters and analyze outputs generated by the software, they cannot analyze or comprehend the steps that led to those results.

Although it may seem counterintuitive, generative design software can actually produce far too many choices. It can be a long and involved process to sort through hundreds or even thousands of design iterations searching for the optimum model.

Browse all the Dassault Systèmes store applications

We feature in our store some of our best software to design, collaborate and innovate throughout the entire product lifecycle.

Content related to Generative design

Topology optimization vs generative design

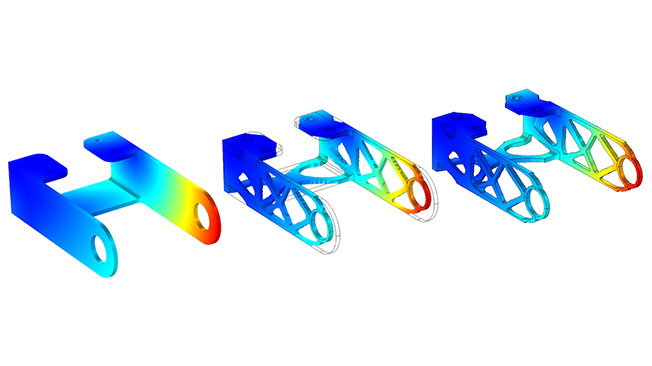

While generative design and topology optimization both incorporate AI and sophisticated CAD and CAE software, they are not interchangeable terms.

Topology optimization is a structural enhancement tool as opposed to generative design, which is an engineering methodology.

Topology optimization is used to refine an existing CAD design to meet certain specifications, while generative design creates a design from scratch using complex algorithms.

How does generative design improve an engineer’s role?

Engineers can use generative design software to cut down on the amount of time they spend on design iterations. Instead, engineers can focus on improving products as a whole by spending less time on each part. More time can be spent concentrating on high-level tasks rather than wasting hours doing simple repetitive work.

What are the applications of generative design?

Generative design is often used for lightweighting a product as AI is especially good at producing architected materials. Many engineers and designers rely on generative design software to optimize thermal management when designing heat sinks and the like. The process of producing customer-specific products can also be made faster and less resource-intensive using generative design.

Where is generative design used?

Generative design methodology is used in a wide range of industries that manufacture products, parts, and machinery. Some generative design examples include:

Automotive

The automotive industry uses generative design for weight reduction purposes and to design parts with enhanced safety features and improved aesthetic qualities. Chassis, grilles, accessories, and hydraulic manifolds have all been optimized using generative design.

Aerospace

Aerospace manufacturers apply generative design methodologies to manufacture more environmentally friendly, more efficient, and much lighter aircraft. Drones, rockets, satellites, and aeronautical components are also created using generative design.

Healthcare

Many modern medical devices, prosthetics, and implants have been developed using generative design methodologies. Biomedical devices can be produced in less time and customized to meet specific needs.

Manufacturing

The manufacturing industry has made good use of generative design for lightweighting and automating the manufacturing process. Companies can create manufacturing-ready products for less cost than traditional design methods.

Consumer products

Many companies use generative design to speed up the process of developing consumer goods. The speed of generative design gives companies an edge when it comes to differentiation and innovative design.

What are the preferred manufacturing methods for generative design?

Major companies are now employing generative design methods to optimize the way they manufacture products, parts, and machinery. Generative design techniques are used to optimize the way products are made via casting, additive manufacturing, CNC machining, and by using injection molding processes.

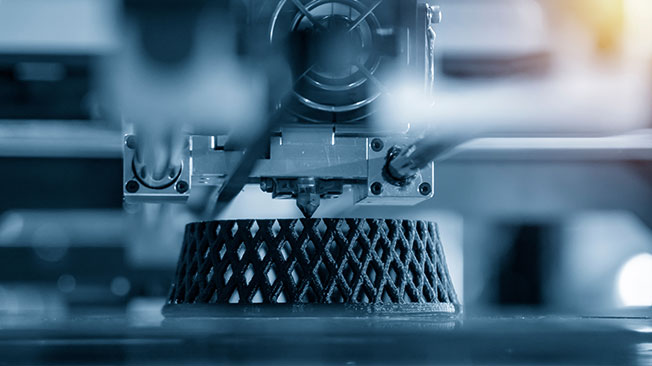

Generative design and 3D printing

Generative design is often used in conjunction with 3D printing techniques. 3D printing enables improved manufacturability of highly complex parts that would be too costly to produce using traditional manufacturing processes. Generative design allows for the creation of highly optimized pieces that would be too complex for humans to generate.

Generative design - Conclusion & Perspectives

As AI becomes ever more advanced and cloud computing technologies expand, there is a good chance that generative design will become the preferred industry product design standard for designers and engineers.

Because generative design can produce hundreds of highly complex design iterations means that incredibly innovative and often surprising solutions can be found, many of which would be impossible for the human mind to come up with. The power of generative design will enable engineers to develop more energy-efficient, less resource-intensive, and more sustainable products and manufacturing processes.

While the potential of generative design is huge, it will never replace skilled designers and engineers. However, this amazing tool will continue to revolutionize how we design and produce products, parts, and machinery.

Why choose Dassault Systèmes for your generative design needs?

The power of the 3DEXPERIENCE platform

The 3DEXPERIENCE platform gives you access to a wide range of Dassault Systèmes software solutions powered by highly advanced cloud computing technology. By using multiple cloud-hosted data banks, the platform gives you all the power of generative design without the need to have expensive on-premises IT infrastructure.

The 3DEXPERIENCE platform is an ideal remote working solution. Colleagues can store and share files and collaborate on projects securely and in real time via one digital environment. Visit the Dassault Systèmes store to discover how our solutions can help you break free from traditional IT models.

More than 40 years of CAD PLM experience

Expert engineers across the globe in a wide variety of sectors choose to use Dassault Systèmes roles. Over the last four decades, we have proven beyond a doubt that we can deliver the solutions that professional designers, architects, artists, and engineers need. From our remarkable work in the aerospace industry in the 1970s, we have continued to create, innovate, and revolutionize.

Premier Dassault Systèmes roles such as SOLIDWORKS and CATIA are now the standard for the automotive, construction, and aeronautical industries. These powerful CAD, CAE, and PLM solutions allow designers and engineers to develop more sustainable and effective products, vehicles, and structures using fewer materials, in less time, and for less cost.