Product Data Management

Empower your organization to connect, manage and control product information, ensuring seamless collaboration, version control and traceability across global teams throughout the product lifecycle

What is Product Data Management?

Product Data Management (PDM) is a system for managing and publishing product data, serving as a central repository for all information related to a product. It is a critical business strategy that ensures all stakeholders have access to a single source of truth for design data, documents, parts information and manufacturing requirements. Effective PDM is fundamental for industries like manufacturing, automotive, aerospace and electronics, where complex products require meticulous tracking of every component and change. Without a robust PDM system, organizations risk data silos, costly errors, version control issues and significant delays in product development.

Optimizing Product Development

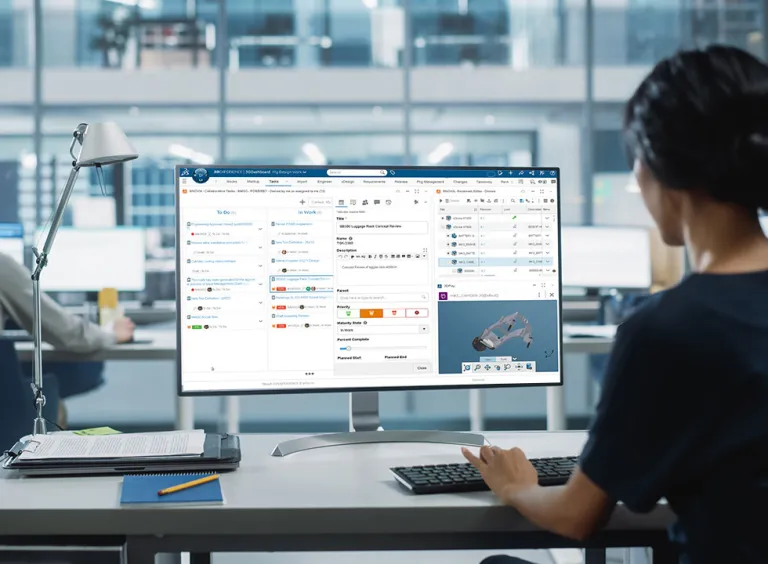

A well-implemented Product Data Management (PDM) system centralizes all product-related data—spanning CAD models, technical drawings, specifications and documentation—within a single, highly secure data vault. This secure repository protects intellectual property through robust access controls and enables cross-functional teams to collaborate efficiently, ensuring everyone works from the most current data and reducing miscommunication. Modern PDM solutions integrate seamlessly with CAD platforms, ERP and PLM suites, enabling real-time data synchronization and automating key business processes such as engineering change management. As a single source of truth, PDM systems reduce errors, speed up time-to-market and boost both compliance and innovation.

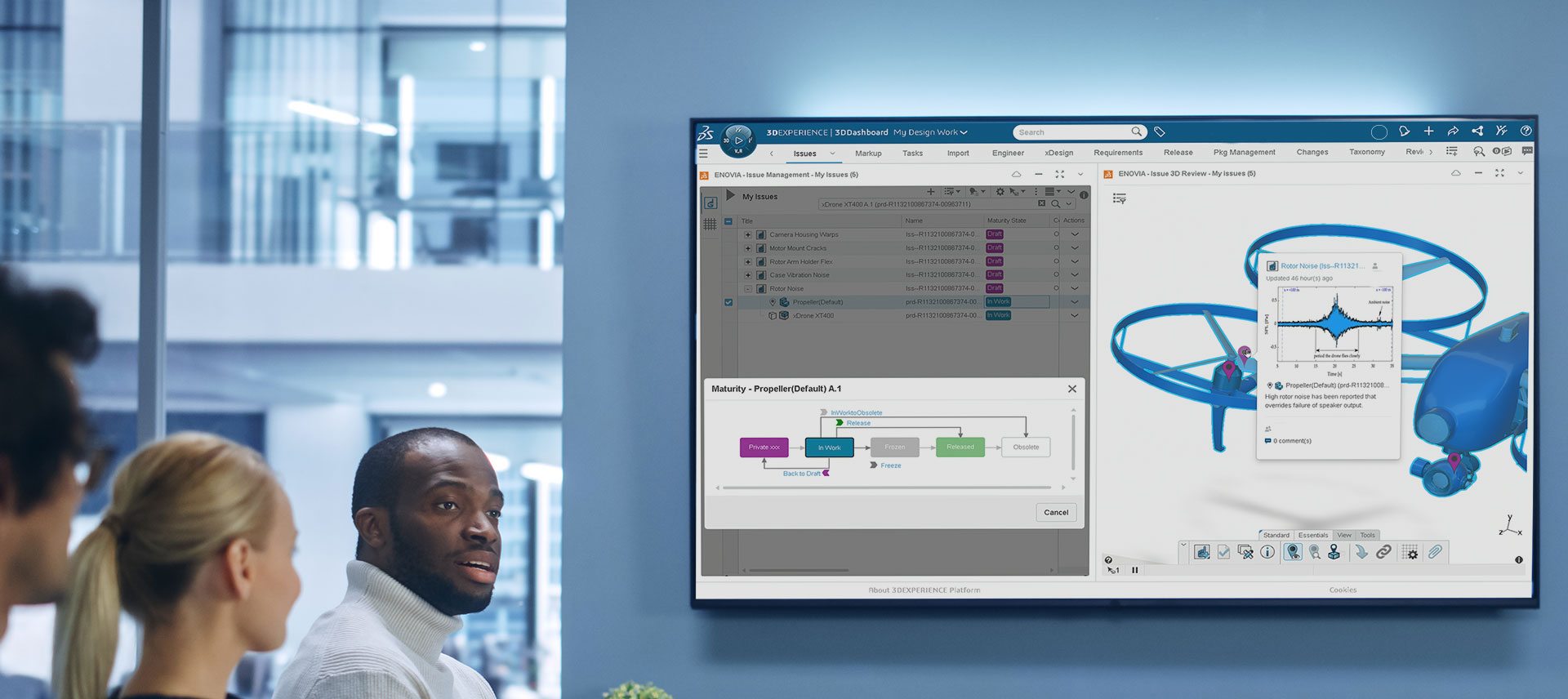

How 3DEXPERIENCE Platform Supports Product Development

The 3DEXPERIENCE platform offers an integrated approach to Product Data Management by centralizing data, processes and teams in a cloud-based environment. It ensures seamless collaboration across departments with real-time, consistent information and enhances product development through robust version control, automated workflows and advanced search capabilities. Fully integrated with multiple CAD applications , the platform enables effective collaboration among engineering and design teams.

Additionally, the platform integrates ERP and other enterprise systems to provide end-to-end visibility across the product lifecycle. Built-in analytics and reporting tools deliver actionable insights, empowering better decision-making. This scalable solution adapts to the evolving needs of modern enterprises, making it a vital part of any future-ready PDM strategy.

Core Pillars of Product Data Management

Centralized Data Vault

Establish a single, secure repository for all product data, including CAD files, documents and metadata, to eliminate data silos and inconsistencies.

Revision Control

Manage and track all revisions to product data, ensuring that team members always work from the "right" revision and preventing accidental overwrites or use of outdated information.

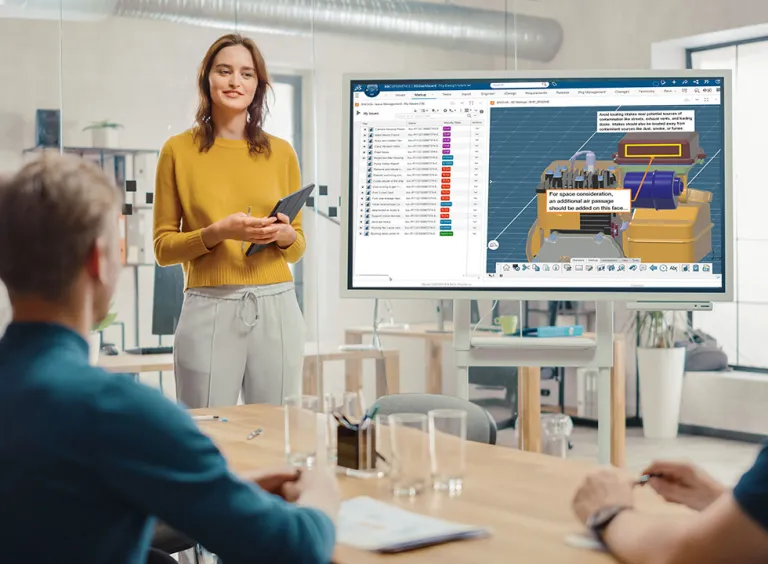

Workflow and Process Management

Automate and standardize business processes, such as engineering change orders (ECOs) and approval cycles, to improve efficiency, accountability and traceability.

Efficient Multi-CAD Data Management

PDM solutions integrate with various CAD tools, allowing efficient management and collaboration across different design environments.

Collaboration and Accessibility

Enable secure, role-based access to product information for all stakeholders, whether they are in the next office or across the globe, facilitating concurrent engineering and reducing delays.

Sustainability and Product Data Management

How PDM Supports a Sustainable Product Lifecycle

Sustainability is a crucial element of modern product development and PDM provides the foundational data governance needed to achieve environmental goals. By centralizing information on materials, suppliers and manufacturing processes, a PDM system enables organizations to make more informed, sustainable choices. It provides the traceability required to track material origins, document compliance with environmental regulations like RoHS or REACH and support life cycle assessments. This structured approach to data ensures that sustainability considerations are integrated from the earliest design stages, helping businesses reduce their environmental impact, meet regulatory demands and build products for a circular economy.

Use Cases: Product Data Management

Engineering Design and Collaboration

PDM fosters collaboration and ensures engineering data integrity in design by allowing simultaneous work on different product aspects while maintaining version control, reducing errors and speeding up the design process.

Manufacturing and Production Planning

PDM bridges design and manufacturing by providing accurate, up-to-date product data, ensuring manufacturing aligns perfectly with the latest specifications, crucial in industries like aerospace.

Supply Chain Management

PDM enhances collaboration with suppliers by giving controlled access to the latest product data, allowing quick adaptation to design changes and maintaining synchronization in complex supply chains.

Quality Assurance and Compliance

PDM maintains quality and compliance by centralizing documentation and providing a clear audit trail, simplifying regulatory compliance and facilitating quicker resolution of quality issues.

Key Features of Product Data Management

Streamlining PDM on the 3DEXPERIENCE Platform with Collaborative Industry Innovator Role

The Collaborative Industry Innovator role serves as a foundational application for secure, multi-disciplinary collaboration, enabling teams to define and deliver innovative products with complete flexibility and traceability. It enhances decision-making by providing real-time data access and ensuring process continuity through robust content management.

Key capabilities include browser-based 3D visualization, advanced product structure navigation and the ability to manage a single, unified product definition directly from various CAD applications. This eliminates data silos and facilitates concurrent design, streamlining the entire product development lifecycle from within a secure and organized environment.

Customer Stories

ENOVIA's product data management solution has been successfully implemented across various industries, delivering tangible benefits to customers.

NAAREA

ENOVIA on the 3DEXPERIENCE platform manages the high volume of data being produced and makes it easy for users to securely store and access the information they need. It also supports change and configuration management, which is critical as each subsystem within the reactor reaches different maturity levels.

As our designs evolve, we need to know which versions to work on and at which stage of the development process every component and system is. ENOVIA ensures full data traceability, so we don’t lose sight of where we are and which subsystems to validate.

Want to Learn More?

Explore the content below to learn more about PLM solutions

FAQs on Product Data Management

Also Discover

Learn What ENOVIA Can Do For You

Speak with an ENOVIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right ENOVIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering.