Manufacturing Bill of Materials

Revolutionizes product creation by providing a comprehensive blueprint for efficient manufacturing processes, cost control and quality assurance

What is a Manufacturing Bill of Materials?

A Manufacturing Bill of Materials (MBOMs) is a document that lists all the parts, components and assemblies required to produce a finished product. Unlike the Engineering Bill of Materials (EBOM), which focuses on design structure, the MBOM is specific to the manufacturing process, detailing which and how parts are related during production.

Why is an MBOM Crucial?

An MBOM is crucial because it bridges the gap between design and manufacturing, ensuring all materials and processes are accounted for. By detailing component relationships, it optimizes product assembly, streamlines sequences, reduces errors and supports lean manufacturing. It also enables precise inventory management, maintaining optimal stock levels, minimizing carrying costs and preventing obsolescence.

Additionally, an MBOM provides essential data for production planning and scheduling, improving resource allocation, equipment utilization and capacity planning. Together, these capabilities help manufacturers enhance efficiency, control costs, maintain quality and manage supply chains effectively.

Core Pillars of MBOM

Innovation-driven approach

Dassault Systèmes focuses on continuous innovation in MBOM solutions, staying ahead of industry trends.

Seamless integration

MBOM solutions on the 3DEXPERIENCE platform integrate seamlessly with other PLM and enterprise systems for a cohesive workflow.

Scalability and flexibility

Dassault Systèmes' MBOM solutions are designed to scale and adapt to diverse manufacturing needs.

Industry-specific expertise

Dassault Systèmes offers tailored solutions that address unique MBOM challenges across various industries, from the most basic to highly complex.

Sustainability and MBOM

Driving Eco-Friendly Production

An MBOM supports sustainability by identifying eco-friendly materials and greener production methods. It helps reduce waste, optimize resource use and manage hazardous materials while ensuring compliance with environmental regulations. MBOM also aids in analyzing the environmental impact of product variants for more sustainable designs.

The Dassault Systèmes' Approach to MBOM

Integrated PLM Solutions

Dassault Systèmes offers comprehensive Product Lifecycle Management (PLM) solutions that seamlessly integrate MBOM creation and management. Their PLM system enables businesses to manage product data and processes from ideation to end-of-life, ensuring consistency and efficiency throughout the product lifecycle.

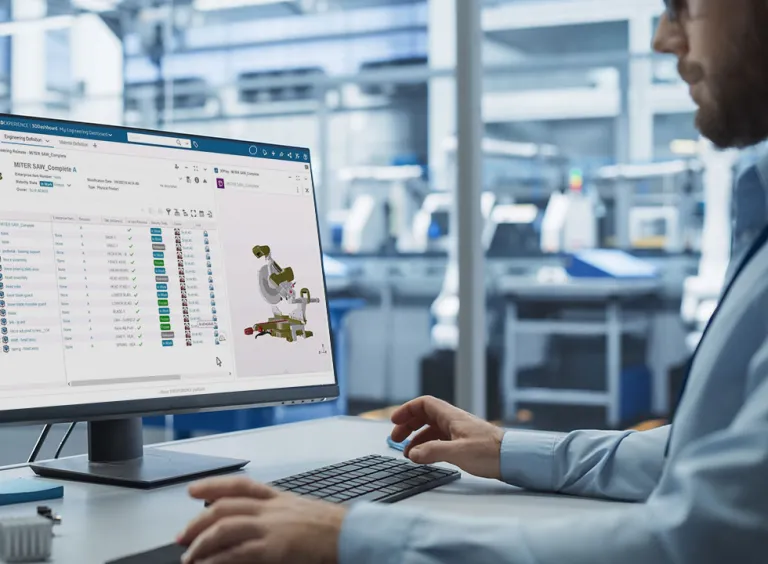

MBOM Creation & Management

The ENOVIA brand of Dassault Systèmes provides powerful tools for creating and managing BOMs. These tools enable manufacturers to efficiently generate MBOMs from EBOMs, incorporate manufacturing-specific information and maintain consistency across different BOMs. The 3DEXPERIENCE platform supports collaborative MBOM development and management.

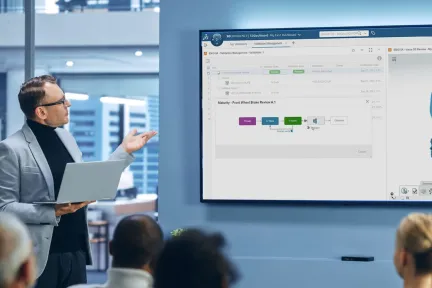

Collaborative MBOM Workflows

ENOVIA's approach emphasizes collaborative workflows in MBOM management. This facilitates seamless communication and data sharing among different teams involved in the product lifecycle. The collaborative 3DEXPERIENCE environment ensures that changes in design or manufacturing processes are immediately reflected in the MBOM, maintaining accuracy and reducing errors.

Key Features of MBOMs

MBOM & Virtual Twin Technology

Driving Quality and Agility with a Robust MBOM

Integrating an MBOM with Virtual Twin technology allows manufacturers to create digital simulations of products and processes, optimizing them before implementation.

This reduces time, costs and errors, enabling real-time monitoring, virtual inspections and improved quality control, minimizing the need for physical prototypes.

Customer Stories

Uncover the Value of 3DEXPERIENCE-based MBOM Creation and Management

Hyundai Everdigm

Hyundai Everdigm migrated from its legacy PLM system to Dassault Systèmes’ 3DEXPERIENCE platform, using industry solution Digital Equipment Continuity to transform its product development, optimize its manufacturing operations and achieve a continuous data flow across the entire product lifecycle.

Designers confirmed sales order specifications by email, put design data into the PLM, distributed drawings offline and then notified relevant departments individually by separate emails or phone calls. Now, communication and product data is managed centrally so that EBOM configurations are verified in the planning phase, saving time and money throughout development.

Take the Next Step

Dive into the content below to see how PLM solutions can support your business.

FAQs- MBOM

Also Discover

Learn What ENOVIA Can Do For You

Speak with an ENOVIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right ENOVIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering.