Engineering Change Management

Engineering change management streamlines product evolution, enhances team collaboration, and ensures the accurate and efficient implementation of changes

What is Engineering Change Management?

Engineering change management (ECM) is a systematic approach to handling modifications in product design, development and manufacturing processes. In today's fast-paced manufacturing environment, it has become essential for companies to maintain the agility necessary to address changing market demands and technological advancements. This encompasses the identification, evaluation, and planning of components, as well as the implementation of changes to products, processes, or documentation.

Why is ECM Important for Modern Manufacturing?

Engineering Change Management is vital because it helps maintain product integrity, reduce errors, minimize disruptions to production, and facilitate seamless communication across teams. By providing a structured framework for managing changes, it enables manufacturers to adapt quickly to market needs while maintaining control over their processes and product quality.

This approach is essential in modern product development, where complex supply chains, global operations and strict regulatory requirements demand a high level of coordination and traceability in all aspects of production.

How the 3DEXPERIENCE Platform Supports ECM

The 3DEXPERIENCE by Dassault Systèmes transforms engineering change management into a seamless, collaborative process. It integrates engineering, design and manufacturing teams within a unified digital ecosystem, offering a single source of truth for all product-related data.

Using a centralized, cloud-based architecture, the platform connects all stakeholders, ensuring everyone remains synchronized—no matter where they are located. From initiating change requests to implementing them, the platform accelerates the decision-making process, improves time-to-market and enhances overall resilience.

Core Pillars of Engineering Change Management

Collaboration

Establish effective communication to maintain alignment across teams.

Traceability

Maintain comprehensive records to ensure compliance and accountability.

Impact Analysis

Evaluate potential effects of changes to proactively mitigate risks.

Automation

Optimize workflows to enhance process efficiency and consistency.

Data-Driven Decision-Making

Leverage real-time data for informed decision-making.

Engineering Change Management & Sustainability

Driving Eco-Friendly Product Evolution

Engineering change management in Product Lifecycle Management (PLM) promotes sustainability by enabling eco-friendly design changes and process improvements. This framework helps reduce waste, enhance energy efficiency, minimize environmental impact, and optimize the Bill of Materials (BoM) for sustainability. It also aligns sustainability goals with cost savings and improved product performance.

Use Cases: Engineering Change Management

Collaborative Project Management

Dassault Systèmes enables seamless collaboration in product development by connecting teams, data and processes. Its solutions enhance visibility, accelerate decision-making and ensure project alignment across global engineering teams.

End-to-end Model Based Solutions

Dassault Systèmes integrates engineering processes through a unified platform, combining modeling, simulation, and validation tools. Its solutions enhance collaboration, ensure traceability, and support adherence to quality and certification standards.

Integrated PLM solutions

Dassault Systèmes offers comprehensive product lifecycle management (PLM) solutions that integrate seamlessly with engineering change management processes. These solutions provide a unified platform for managing product data, workflows and change requests across the entire product lifecycle, enhancing collaboration and streamlining product development.

Key Features of Engineering Change Management

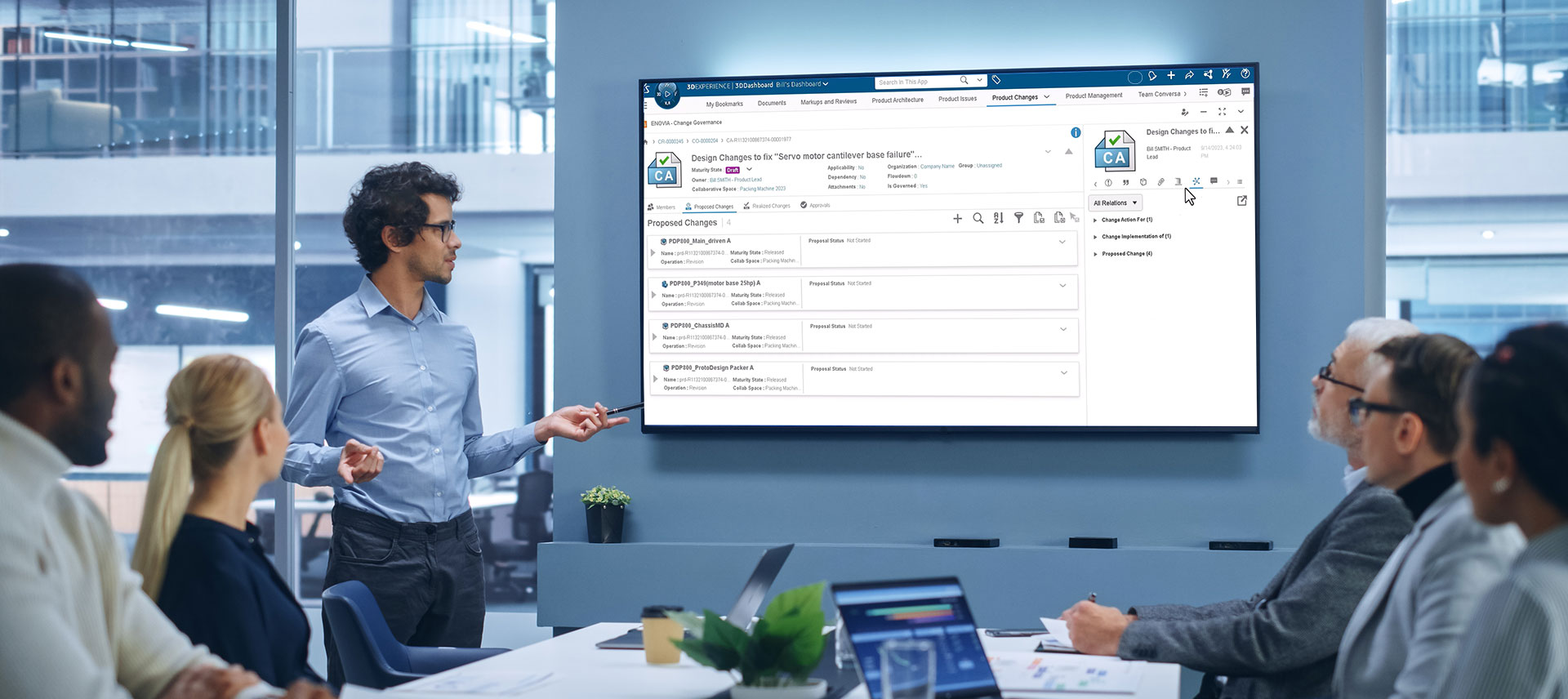

Streamlining Change Management on the 3DEXPERIENCE Platform with the Change Manager Role

The Change Manager role on the 3DEXPERIENCE Platform delivers a strategic, closed-loop collaborative change process that empowers organizations to effectively manage and communicate change decisions across all impacted domains. By providing a single, tailored change methodology, it ensures seamless coordination across teams and workflows, driving operational efficiency and enhancing global product development.

By streamlining the execution of change processes, Change Manager significantly reduces the time and cost across the product lifecycle. It leverages intelligent change management rules, automation and consistent procedures to promote accountability and traceability at every stage. From product governance to work-in-process scenarios, the platform orchestrates change activities in a comprehensive, traceable manner, meeting both organizational and compliance requirements.

How Companies Use ENOVIA PLM Solutions

Customer Stories

Dongfeng Automobile Corporation

The ability to integrate electrical design into the same 3D model while leveraging the single data environment provided by the 3DEXPERIENCE platform also meant we encountered as much as 70% fewer design problems. The quality of our design improved significantly.

With the 3DEXPERIENCE platform, we can reduce costs by improving R&D efficiency and product quality, as well as accelerating product launches. In turn, those savings get passed on to our customers.

Leveraging Virtual Twin Technology in Engineering Change Management

Virtual twin experiences (VTEs) empower organizations to explore and simulate new innovations, enabling teams to test ideas and predict outcomes in a risk-free virtual environment. Engineering change management complements this by ensuring that decisions derived from VTE insights are seamlessly integrated into the product development process. It maintains accuracy and reliability, fosters collaboration and aligns updates with organizational goals.

By providing traceability for compliance and audits and enabling impact analysis, it reduces risks and supports informed decision-making. Additionally, it accelerates innovation and enhances predictive maintenance, ensuring the virtual twin remains a dynamic and reliable representation of physical assets.

Want to Learn More?

Explore the content below to learn more about Engineering Change Management.

Engineering Change Management FAQs

Also Discover

Learn What ENOVIA Can Do For You

Speak with an ENOVIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right ENOVIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering.