Navigating the Rise of IoT Solutions in Manufacturing

The Internet of Things (IoT) continues to spread its connections across the world. But if manufacturing industries want to seize this opportunity, they need to start building structures that can accommodate it.

How prepared are your operations for radical connectivity?

What is IoT?

Perhaps the most famous scene from Disney’s 1940 musical Fantasia is where Mickey Mouse conducts an army of sentient buckets and mops to carry out chores to the tune of Paul Dukas’ The Sorcerer’s Apprentice. Things quickly go wrong for Mickey, but that fantasy of sentient machines performing tasks for us is a seductive one.

And what was once a flight of fantasy is now something manufacturing industries are increasingly grappling with every day, driven by the rise of the Internet of Things (IoT).

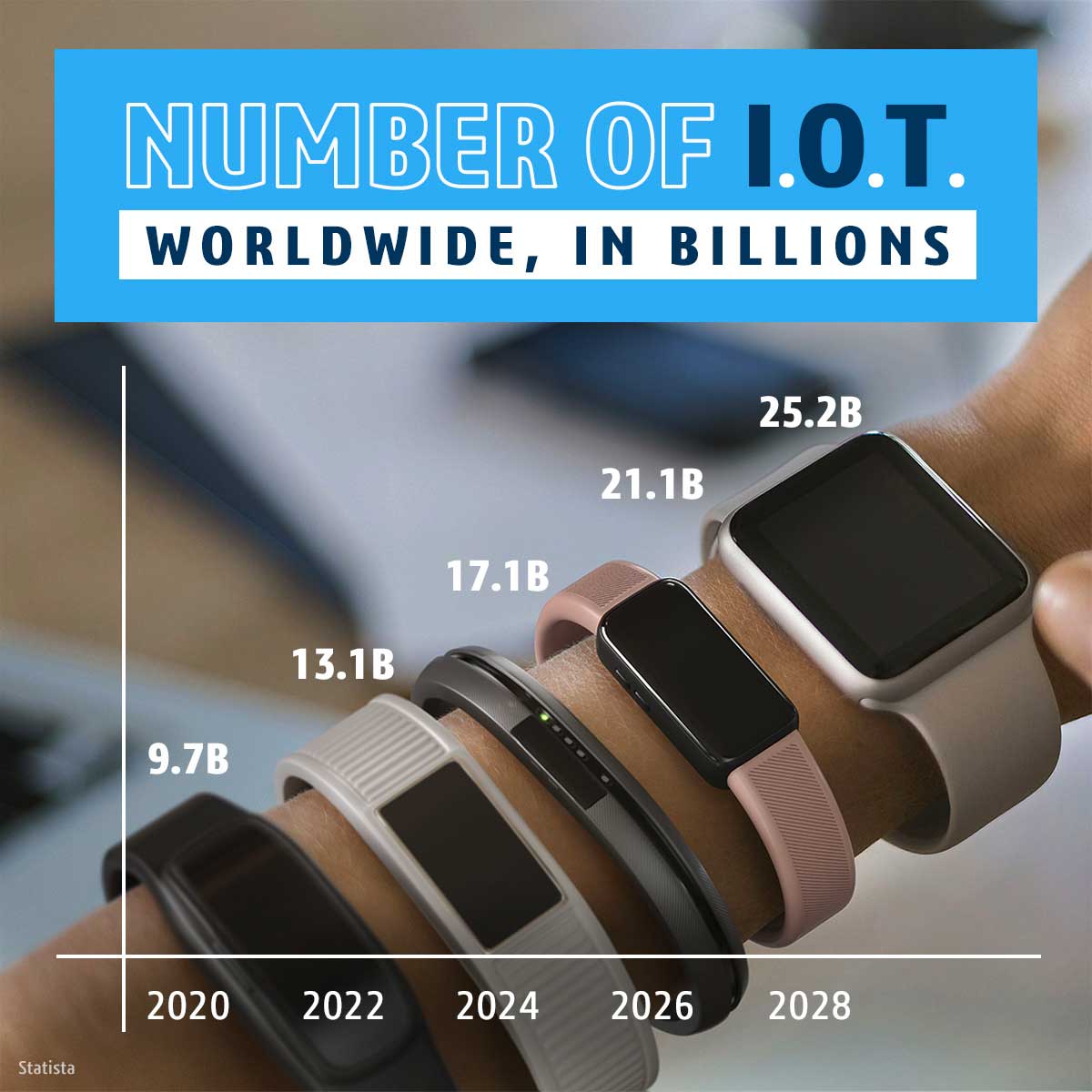

It can feel like a trend that has been hyped for more than a decade, but IoT solutions are truly on the rise. According to data from the WEF, spending on IoT is expected to reach $1.1 trillion by 2023 and manufacturing spending will account for a significant percentage of that. In fact, by 2024, it’s anticipated that 70% of all IoT connections will be industry. The factory of the future is here.

And the next decade will see the IoT landscape mature far further. “The rise of 5G, the emergence of new communication standards, more and more affordable technologies, and the willingness to connect the unconnected to optimize global systems of operations will drive the dramatic expansion of the collective network of the global IoT market,” says Stephane Sireau, Vice President, High-Tech Industry, Dassault Systèmes.

Sustainability pressures are also helping promote the adoption of collective networks: “In part, this has all been accelerated by the climate crisis, and the desire to optimize overall energy consumption, starting with the improvement of the grid energy and home automation systems,” says Sireau.

Curious about how other manufacturing industries respond?

Respond to today's challenges with our bespoke solutions

How is IoT being used in industry?

It’s clear that IoT is no longer a what-if scenario. It’s here and only growing more ubiquitous. And that’s a good thing. IoT, used effectively, can transform how businesses understand and maintain their operations. But what is IoT and how does it work?

“The Industrial Internet of Things allows for more flexibility, more automation, and better, real-time control and connectivity inside and between factories,” says Sireau. “In turn, this results in higher throughput and up-time, all while reaching yield and quality targets. It means everything from smart product development, to smart manufacturing, to smart recycling.”

Specific applications include:

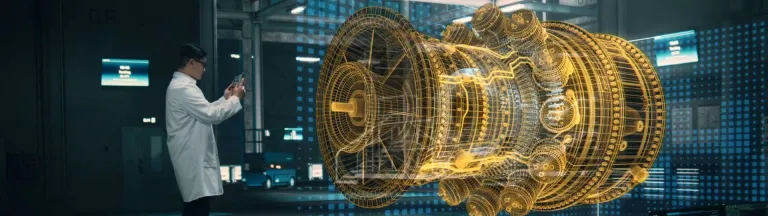

1. Interactive shop floor and live monitoring: Allows supervisors to visualize their network of plants and logistics assets, and optimize performance across the value chain

2. Virtual commissioning: Enables plant managers to model the installation and behavior of new industrial assets

3. Virtual and augmented reality training: Trains personnel in the correct use of equipment in a safe, virtual but realistic environment

4. Human-robot collaboration: Allows for the accelerated deployment of safe, productive, high-throughput robotics solutions

5. Predictive maintenance and incident management: Better collection of data allows for machine malfunctions to be recognized ahead of time and addressed in a cost-effective way

Sophie Proust, Industry Market Intelligence Manager, Dassault Systèmes, also highlights the sustainability benefits of the technology: “IoT connectivity allows us to keep track of how products are produced and used, through every step of their life cycle, meaning recyclers will be much better informed as to how to recycle or refurbish that product properly.”

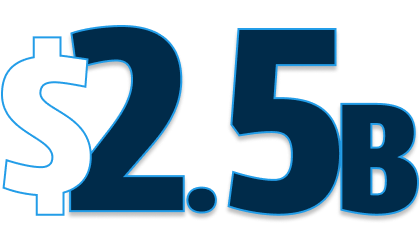

And IoT won’t just change how manufacturers make things either. It will change what they make. Cars, for example, are increasingly connected devices – research suggests that cars will account for 2.5 billion IoT connections by 2030, accounting for 23% of all IoT spend by 2030, across an increasingly smart industry. The rise of connected products then, also necessitates a shift in manufacturing approaches.

How can businesses use IoT and what challenges might it present?

The integration of IoT across manufacturing industries is not straightforward, however. Contemporary approaches to IoT can be static and siloed. Effectively implementing a full-scale industrial IoT approach means moving from an ad hoc, device-by-device approach to a holistic strategy, incorporating elements like Mobile Private Networks (MPNs), embracing emerging industry standards, and doing it all while avoiding excessive downtime in operations.

And as with any digital technology, the more connected devices you add, the wider your cyber vulnerability profile becomes. This can result in some rather embarrassing mishaps – like an incident in 2017 in which cybercriminals were able to rob a casino via an improperly secured IoT fish tank.

Therefore, as with all transformative technologies, implementing IoT throughout your enterprise requires careful selection of the right solutions, intelligent integration of those elements into your manufacturing ecosystems, and care taken to ensure that security gaps are covered across all connected devices.

“Most of what we think now as normal objects will become connected at some point in the near future – from lighting to capital equipment – and they will all be generating a lot of data,” says Proust. “It’s important to get systems and frameworks in place now that govern how you manage and transfer data, and which will help you embrace and adapt to new realities, from security, to data hosting, to system architectures.”

The rise of 5G, the emergence of new communication standards, more and more affordable technologies, and the willingness to connect the unconnected to optimize global systems of operations are driving the dramatic expansion of the IoT market.

Other Trends

Discover more with our Manufacturing Industries

- Aerospace & Defense

- Consumer Packaged Goods & Retail

- Home & Lifestyle

- High-Tech

- Industrial Equipment

- Marine & Offshore

- Transportation & Mobility

Bridge the gap between the virtual and real world to accelerate from concept to operations.

Discover how the 3DEXPERIENCE® platform drives innovation in the industry with CPG solutions for design, simulation and AI-driven forecasting.

Virtual Twin Experiences for Sustainable Innovation – Helping Manufacturers Improve Consumer Products

Simplify and accelerate innovation to create more valuable consumer experiences.

How to remain agile and responsive in a dynamic marketplace

Digitalize manufacturing to deliver made-to-order innovation.

A connected industry changes the way designers innovate. They can harness real-time big data to build synergistic systems and craft exciting product experiences.

Accelerate the sustainable transformation of the Marine & Offshore industry.

Driving vehicle innovation toward the mobility of the future

Future profit will come from upgradeable, electric autonomous vehicles.

THE WORLD NEEDS MANUFACTURERS

A MANIFESTO FOR CHANGE