Design Innovative Experiences With IIoT and Digital Twin

A connected industry changes the way designers innovate. They can harness real-time big data to build synergistic systems and craft exciting product experiences.

The industrial internet of things (IIoT) is ubiquitous for Industry 4.0 manufacturers. Combined with 5G connectivity, the value of real-time data in equipment performance monitoring or predictive maintenance has long since established itself. This hyper-connected network lays the foundation for smart manufacturing – but it can also transform how designers, engineers and planners operate.

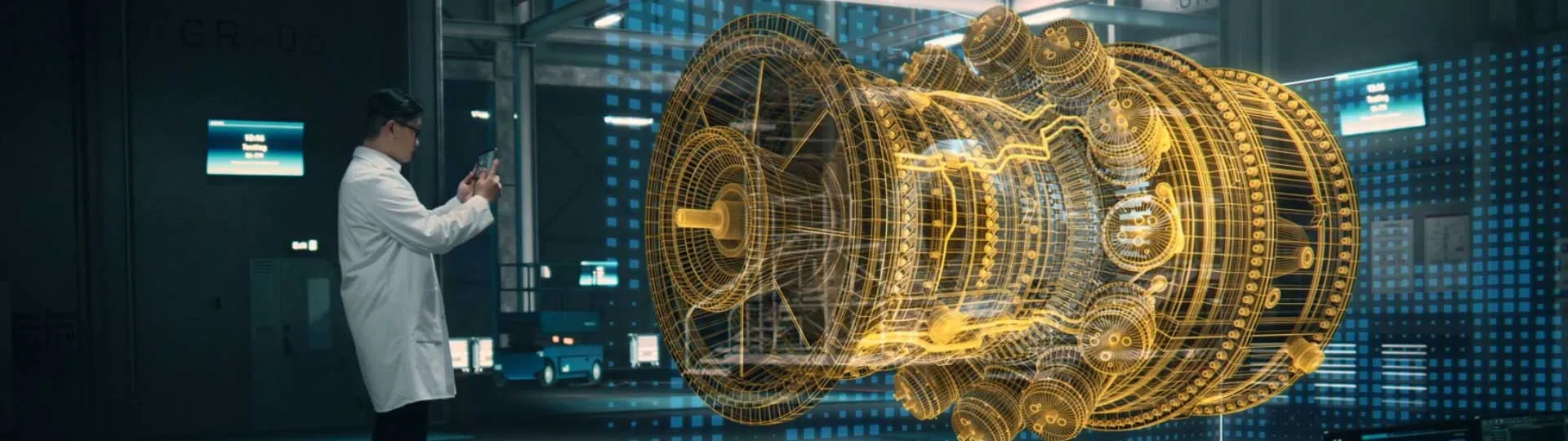

When sensors and devices capture data, designers and planners can analyze the learning experiences within a virtual counterpart of a product or process, otherwise known as the digital twin. This connection helps designers understand what customers want and reshape products to deliver the right experience. As for complex systems such as ports or manufacturing warehouses, the digital twin allows planners to integrate isolated data sources and turn them into insights for more resilient operations.

Design Innovation and Excellence in a Connected Industry

Learn how designers can leverage 5G-IIoT data to elevate decision-making and create new experiences.

What Does IIoT Bring to the Digital Twin in Manufacturing?

IIoT harnesses information from the real world to constantly enrich and update the digital twin. By constructing a closed-loop integration between the twin and its physical counterpart, IIoT accurately models all elements of the manufacturing ecosystem so that designers and planners have complete visibility into products and processes. This real-time view aids decision-making and boosts strategy, design and production operations.

But interpreting sensor data can be challenging, especially when it’s not contextualized. This is where virtual twin technology helps. Going beyond digital twins, the virtual twin maps real-time information onto the 3D model of the system so designers and planners can visualize the data and take action. IIoT, enabled by the virtual twin, establishes a connected industry that fosters collaboration across the entire value network.

Move the slider below to see how cloud connectivity shortcuts the normal innovation process and links designers directly to customers.

The benefits of IIoT for designers are endless. It closes the distance between the designer and the customer while helping design teams capture a product’s live performance, understand the entire lifecycle and predict possible failures. Big data drawn from sensors and devices power advanced technologies such as artificial intelligence and predictive analytics so that teams can generate new insights and craft progressive product experiences.

As for engineers and planners, sensor data on an integrated platform unifies all the different equipment and subsystems within a factory, airport or seaport. As a result, a single source of truth allows planners to connect, comprehend and better supervise a system of systems. This generates situational awareness of operations in real time, so planners can identify and mitigate bottlenecks while building agile and resilient systems.

How Does Real-Time Data Improve a System of Systems?

Sensors collect equipment data in the field and map the information onto the virtual twin. Planners can track how each asset behaves and detect deviations from normal operating conditions to conduct predictive maintenance.

With virtual twin technology, IIoT transforms these fields:

- Product Design

- Systems Design

- Manufacturing Planning

Product Design

The 3DEXPERIENCE® platform helps designers develop smart, cloud-connected products. They can match failure modes and effects analysis to the product’s real-life use and continuously upgrade designs while accelerating innovation through over-the-air software updates. They can also consider more sustainable designs and circular product lifecycles.

Systems Design

Designers, engineers and planners of systems such as airports or seaports can leverage simulation capabilities in the virtual twin to improve operations. From airport safety and resilience during crises to port and terminal operations that thrive in the future, business-level data from sensors enhance productivity, revenues and asset performance.

Manufacturing Planning

Industrial engineers and planners working within smart manufacturing ecosystems can aggregate massive amounts of data from the global network of factories. This data supports predictive analytics to identify future risks and optimize operations. It’s also used to boost energy efficiency for more sustainable manufacturing processes.

Dassault Systèmes’ 3DEXPERIENCE platform integrates 5G-IIoT capabilities within the virtual twin so designers, engineers and planners can create meaningful experiences for the future.

Read more articles on Connected Industry

Explore our Industry Solution Experiences

Learn more about how our industry solutions can help you to achieve your professional ambition and business objectives