Battery Virtual Twin as a Service

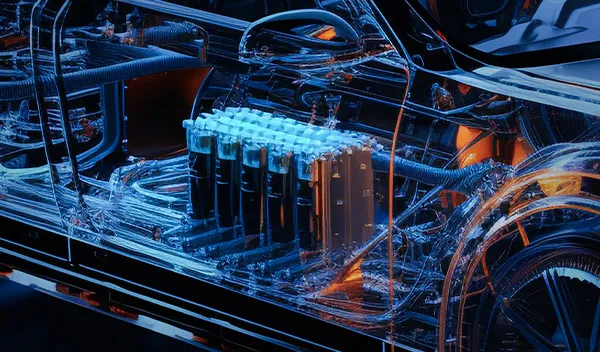

Optimize the battery chemistry and performance with a virtual twin.

We're in a race to meet the growing demand for competitive batteries that are cost-effective, high-quality and safe. To create successful batteries for diverse applications, you need to efficiently manage risks and conflicting requirements. That's where VTaaS (Virtual Twin as a Service) comes in.

Configured by VTaaS, the battery virtual twin provides a safe virtual lab where thousands of metal and electrolyte combinations can be tested in a matter of hours, thus eliminating the need for physical testing and minimizing risks to researchers. As a result, your researchers can spend less time understanding the battery chemistry at the molecular level while identifying different battery configurations.

Maximize Efficiency and Deliver Faster Results

VTaaS transforms your approach to product development by providing a robust battery virtual twin for the entire product lifecycle — from materials to system analysis, battery performance validation and device integration. Read on to learn how companies are reaping the rewards of the battery virtual twin.

- Develop Electrolyte Materials

- Perform Molecular-Level Testing

- Diagnose Battery Cell Performance

- Analyze and Mitigate Failure

Develop Electrolyte Materials

A large OEM sought to develop new, cost-effective electrolyte materials for next-generation battery cells, faster than what physical testing could support. With molecular battery modeling and simulation on the virtual twin, the OEM came up with the optimal electrolyte formulation, which slashed development time by 30%.

Perform Molecular Level Testing

Physical testing could not reveal the chemical reactions in an automotive OEM's batteries, but simulation could. The OEM increased battery innovation rate by 40%, thanks to molecular-level testing on the virtual twin.

Diagnose Battery Cell Performance

When a vendor's battery cells began to perform poorly, an aerospace OEM needed a battery virtual twin to determine the cause of the degradation. By relying on chemistry-based simulation on the battery virtual twin, the OEM implemented measures to boost the performance of battery cells.

Analyze and Mitigate Failure

A personal electronics manufacturer was experiencing high battery failure. To lower the failure rate, the manufacturer developed three hypotheses, which were then tested in a battery virtual twin at molecular and mesoscale levels. Thanks insights gained during virtual testing, the manufacturer made improvements and lowered the failure rate from 9% to 1%.

Fast Track Value in Battery Innovation

Accelerating innovation is crucial to succeeding in today's constantly evolving battery industry. This can be daunting, but with the support of VTaaS, you can streamline your battery development process from start to finish. Powered by the 3DEXPERIENCE® platform, the battery virtual twin helps you:

Innovate and Optimize Battery Performance

Win the battery race by delivering cost-effective, high-quality and safe products with Virtual Twin as a Service (VTaaS).

Related Content

Dassault Systèmes and Verkor Sign MoU

Advance Next-Generation Low-Carbon Battery Development and Manufacturing

Why the EV Revolution Requires Battery Evolution

Tomorrow’s electric vehicles demand a revolution in battery innovation – lighter, more powerful, and more sustainable, delivered at unprecedented scale.

The Model-Based Approach for Battery Innovation and Manufacturing

Secure an advantage to deliver best-in-class batteries with the power of virtual twins.

Battery Traceability: Sustainability's Game Changer

Discover the pivotal role of battery traceability in shaping a low-carbon future with the 3DEXPERIENCE® platform.