Industrial Engineering

Optimize your plant operations through virtual simulation of manufacturing processes and accurate planning with DELMIA Industrial Engineering software.

What is the Value of DELMIA Industrial Engineering Software?

DELMIA Industrial Engineering software is designed to streamline manufacturing operations by integrating tools for 3D modeling, virtual simulation, and process optimization.

Our innovative solutions enable manufacturers to plan, define, and refine operations with precision and efficiency in order to accurately plan with comprehensive 3D process and resource planning tools.

By gaining an accurate virtual production system, manufacturers will save time and increase responsiveness to market fluctuations by tracking real-time production activities, perform schedule changes, launch new programs, introduce model changeovers, and schedule maintenance operations.

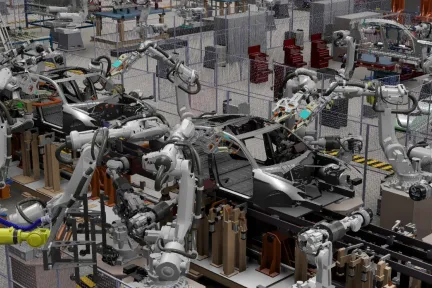

Optimize Operations with Virtual Twin Simulation

At DELMIA, we believe in the power of the virtual world to transform and improve real-world manufacturing. DELMIA's Virtual Twin encompasses three key things: modeling, experimenting, and simulating to optimize and make informed decisions within a virtual space.

Explore all possibilities, identify optimal and robust solutions, then apply to real-world situations from the shop floor to the supply chain. This connection provides the current state of operations and even helps to predict and anticipate future outcomes. This is crucial, for example on the shop floor where the focus isn't merely to solve existing problems, but anticipate potential issues to minimize their impact on our operations, or in distribution of products to effectively fulfill customer orders.

Key Features of DELMIA Industrial Engineering Software

Manufacturing Transformation

DELMIA transforms the way companies optimize, orchestrate, and execute their value networks, from suppliers, to manufacturers, to logistics and transportation providers, to service operators and workforces.

Sustainability Integration

DELMIA supports businesses in adopting greener practices to help address the more than 45% of emissions coming from manufacturing. By rethinking production methods and optimizing resource use, DELMIA helps manufacturers significantly reduce their environmental footprint.

Virtual Twin Technology

Simulate processes virtually to ensure real-life operations run seamlessly. The virtual twin allows manufacturers to test and refine production strategies, ensuring sustainability and efficiency before implementation.

Our Industrial Engineering Solutions

Design, Model, and Optimize the manufacturing systems of the future with limitless possibilities. Leverage DELMIA's solutions, from 3D process modeling to virtual factory simulation, to streamline operations and boost efficiency at every stage of production using the powerful 3DEXPERIENCE platform. Explore key industry engineering disciplines today.

Enabling digital continuity between design systems and robotic simulation for seamless integration into manufacturing workflows.

Boost precision, reduce programming time, and streamline workflows with DELMIA’s advanced CAM automation for efficient manufacturing.

Enhance precision, efficiency, and scalability in 3D printing with DELMIA’s advanced additive manufacturing solutions for polymer and metal production.

Finding and Solving Ergonomic Problems in 3D for Safer Workplace in Real Life

Connect People, Ideas, Data and Processes

Unlock the Potential of Service Operations

Unlock the Factory of Tomorrow, Today

Key Benefits of DELMIA Industrial Engineering Software

Create and Accelerate Sustainable Manufacturing

DELMIA Industrial Engineering software ensures an accurate virtual production system representation of the real world to track real-time production activities, perform schedule changes, launch new programs, introduce model changeovers, and schedule maintenance operations.

In addition, DELMIA allows you to create and optimize sustainable manufacturing solutions while providing broad industry and manufacturing model coverage. It supports 12 industries with varied manufacturing models that can be globally deployed across a vertically integrated enterprise or a diversified global manufacturer.

DELMIA Industrial Engineering Software Solutions

DELMIA Industrial Enginering software products are packaged as Roles to get you up to speed faster and work more efficiently with all needed applications available at your fingertips. Select a package that corresponds to your role in an organization.

Our digital transformation ambition is to be paperless and to gain data continuity from development to manufacturing and vehicles’ end of life.

Start Your Journey

The world of digital manufacturing is changing. Discover how to stay a step ahead with DELMIA Industrial Engineering Software.

FAQs about Industrial Engineering Software

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering