CAD techniques for simulation tools

The advent of simulation tools has led to a revolution in the design and testing of products in a wide range of industries, including engineering, manufacturing, aerospace, and automotive.

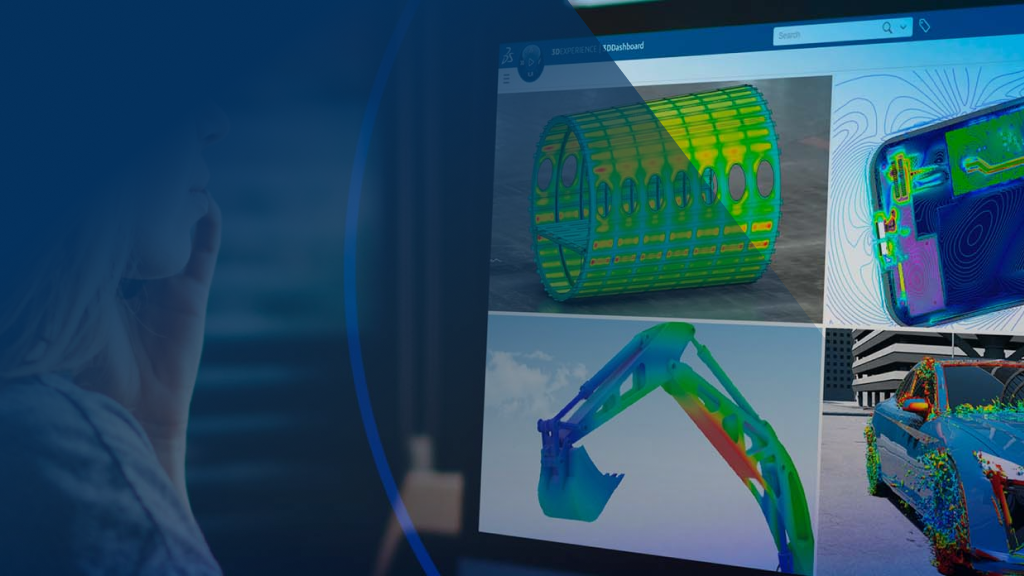

This article considers the transformative force of computer-aided design (CAD)-based simulation software by examining the specific tools and techniques which enable the creation of realistic models of real-world environments and the analysis of these models to enhance product quality, stimulate innovation, and boost productivity.

Simulation tools are revolutionizing how industries design, test, and optimize products and processes. Whether you're involved in engineering, manufacturing, medical, resources, transport, or supply chain projects, simulation software provides a visual model of behavior to help you understand and improve workflows. This article delves into the concept of simulation, the types of simulation software available, key benefits, and how it’s changing the way mechanical engineers approach design and manufacturing.

Mechanical Design Simulation Software

Mechanical design simulation software focuses on simulating the behavior and performance of mechanical components and systems. It uses complex mathematical models to analyze physical forces such as stress, strain, torque, and heat transfer. This software enables engineers to test different design scenarios, evaluate the effects of different materials, and assess mechanical structures under different conditions such as loading or temperature changes. By creating detailed models and simulations, mechanical design simulation software helps engineers optimize designs, reduce errors, and improve overall product performance and safety.

Types of CAD Simulation Software

Computer-aided design simulation software encompasses various types, each of which have specific tools designed for specific applications. Among them:

Benefits of CAD Simulation Software

CAD Simulation software offers numerous benefits across various industries. Four key benefits jump out:

- Early Insights: Simulation provides valuable insights before committing to prototypes or production runs. This helps identify design issues early, reducing costly errors.

- Better Products: By simulating real-world forces, you can minimize late-stage errors, leading to higher-quality products. This reduces product recalls and increases customer satisfaction.

- More Innovation: Simulation allows you to experiment with different scenarios, encouraging innovation and finding new design ideas. It fosters creativity by enabling designers to test unconventional concepts.

- Increased Productivity: Simulation speeds up the transition from concept to production, improving productivity and efficiency. It enables faster design iterations and shorter time-to-market.

CAD Simulation Software Applications

CAD Simulation software has various applications, providing valuable insights into different fields, namely:

The 3DX Simulation Experience: Combining the Best of Both Worlds

The 3DEXPERIENCE platform integrates the strengths of CATIA's advanced CAD capabilities with SIMULIA's powerful simulation tools, creating a unified environment for both. This ensures continuity and reduces errors during data transfer. It supports collaborative workflows so that design and development teams can work together efficiently.

SIMULIA offers a comprehensive range of simulation software for various disciplines, including structural simulation, computational fluid dynamics, electromagnetic simulation, multi-body dynamics, vibro-acoustic simulation, Finite Element Analysis and stress analysis of composite materials. This range enables companies to model, analyze and optimize their products, processes and workflows.

SIMULIA's software portfolio is available as a stand-alone suite of tools for simulation and analysis or encapsulated in the 3DEXPERIENCE platform. CATIA, part of this platform, combines 3D CAD with advanced modeling and simulation techniques. It enables the modeling of cyber-physical systems and allows the simulation of products, processes and systems in a virtual environment.

By integrating SIMULIA and CATIA, 3DX breaks down cumbersome silos and ensures digital continuity. It enables a seamless transition from advanced design to detailed simulation, allowing mechanical designers to perform complex simulations such as finite element analysis (FEA) and composite design without having to switch software. By eliminating the need to import and export data between different tools, this integration reduces manual tasks and errors. It enables in-depth analysis during the design phase, resulting in accelerated development and improved efficiency.

With CATIA's robust 3D design and modeling tools and SIMULIA's comprehensive simulation capabilities, you get the best of both worlds for advanced design and detailed analysis, leading to more accurate results and optimized product development.

Future Changes: What’s Currently Stimulating Simulation?

Simulation has evolved from being a purely physical prototype-based process to a highly advanced digital approach. Early computer simulations required extensive manual inputs and specialized expertise. However, advancements in computing power have made simulations more accurate and user-friendly. Today, automation is becoming a significant trend in simulation software. This trend is driven by advancements in user interfaces, scripting capabilities, and AI-driven tools, which streamline workflows and enhance productivity.

Automation enables simulation software to automatically set up simulations, suggest optimal parameters, and even propose design changes based on simulation outcomes. This reduces time-consuming tasks like manual data input, error correction, and repetitive configurations, allowing engineers to focus on analysis and decision-making. Automation can also facilitate easier interpretation of results and improve communication between teams by providing clearer visualizations and insights. User interfaces are more intuitive, guiding users through the simulation setup and suggesting solutions to potential problems. This automation streamlines workflows and reduces the need for specialized expertise. Generative design and automated modeling are also contributing to a new age of simulation, where engineers can quickly explore countless design options and identify the best solutions.

Conclusion: CAD Simulation Tools are Changing the Face of Mechanical Engineering

CAD Simulation tools are transforming how we design, test, and optimize products and processes. From discrete event simulation to advanced computational fluid dynamics, these tools offer a comprehensive approach to understanding and improving real-world systems. The benefits of simulation include early insights, better product quality, innovation, and increased productivity. As simulation software continues to evolve, it's likely to play an even more significant role in shaping the future of design and manufacturing.