Enhancing Product Design with Topology Optimization

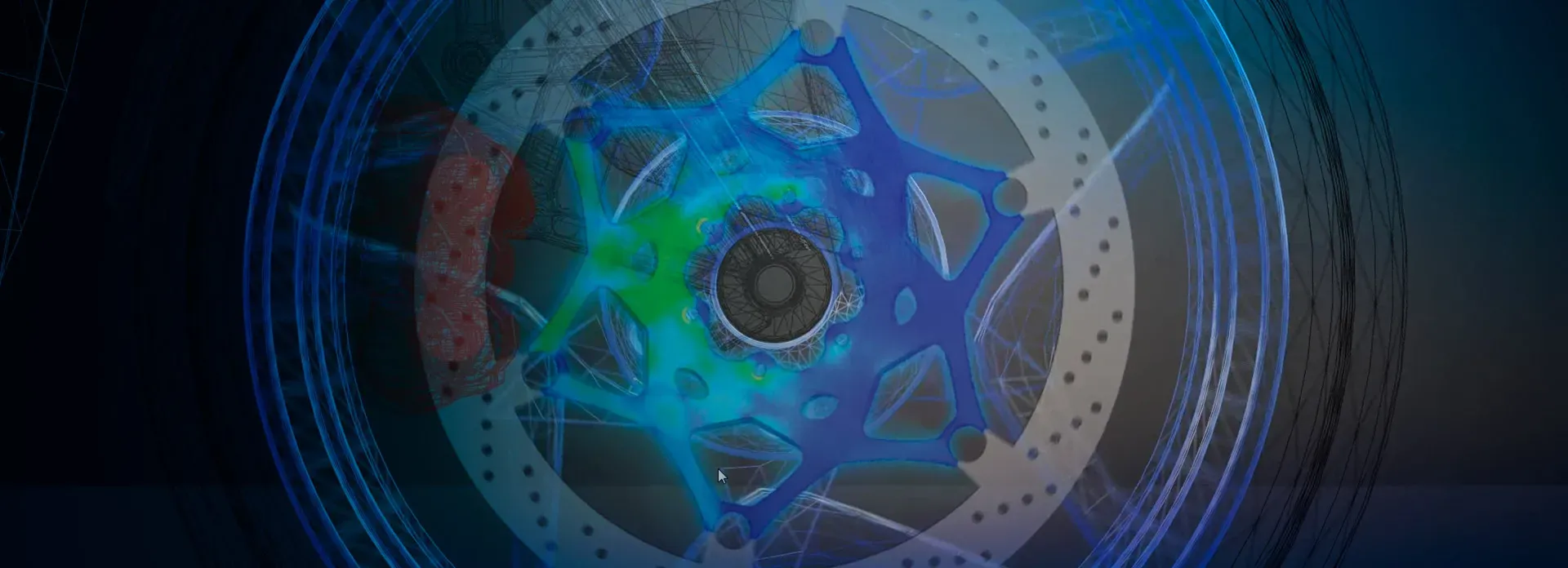

In the realm of product design and engineering, the pursuit of innovation and efficiency is an ongoing endeavour. Topology optimization and generative design have emerged as powerful tools for achieving these goals, enabling engineers to create designs that are both lightweight and structurally efficient.

However, transitioning from the intricate geometries generated through these processes to manufacturable models can present a significant challenge. Fortunately, tools like 3D Sculptor offer a streamlined approach, allowing engineers to bridge the gap between faceted geometries and manufacturable models, thereby harnessing the full potential of these advanced design techniques.

The Promise of Topology Optimization and Generative Design

Topology optimization and generative design represent a departure from traditional design methods by leveraging computational algorithms to explore a vast design space and identify optimal solutions based on predefined criteria. These techniques enable engineers to generate organic and highly efficient geometries that would be difficult, if not impossible, to conceive using conventional approaches. By removing material only where it's necessary to meet performance requirements, these methods can result in lightweight yet structurally robust designs, offering significant benefits in terms of material savings, weight reduction, and overall performance.

Streamlining the Transition with 3D Sculptor

3D Sculptor offers a solution to this challenge by providing a streamlined workflow for transitioning from faceted geometries to manufacturable models. By allowing engineers to overlay solid geometry onto facet geometry, 3D Sculptor enables smoother transitions between the two representations, preserving the intricate features and organic shapes generated through topology optimization and generative design. This approach not only simplifies the conversion process but also ensures that the resulting models are suitable for manufacturing, thereby maximizing the benefits of these advanced design techniques.

Challenges in Transitioning to Manufacturable Models

While the designs generated through topology optimization and generative design offer tremendous potential, translating these intricate geometries into manufacturable models can pose challenges. The output of these processes often consists of faceted geometries, which lack the geometric continuity and smoothness required for traditional manufacturing methods such as machining, casting, or injection molding. As a result, engineers are faced with the task of converting these faceted models into solid geometry that is suitable for manufacturing—a process that can be time-consuming and labor-intensive, detracting from the efficiency gains promised by topology optimization and generative design.

Harnessing the Full Potential of Advanced Design Techniques

By leveraging the capabilities of 3D Sculptor, engineers can harness the full potential of topology optimization and generative design without being encumbered by the challenges of transitioning to manufacturable models. With a streamlined workflow that seamlessly integrates faceted and solid geometry, designers can explore innovative and efficient design solutions with confidence, knowing that they can easily translate their concepts into reality. This empowers engineers to push the boundaries of what is possible, driving continuous innovation and efficiency in product design and engineering.

Conclusion

Topology optimization and generative design offer unprecedented opportunities for creating innovative and efficient designs. However, the transition from faceted geometries to manufacturable models can be a barrier to realizing the full potential of these advanced design techniques. With tools like 3D Sculptor, engineers can overcome this challenge and streamline the design process, enabling them to explore new frontiers in product design and engineering. By harnessing the capabilities of topology optimization and generative design in conjunction with 3D Sculptor, designers can unlock new possibilities and drive innovation in the field of product design and engineering.