The impact of 3D printing and CAD technologies in Mechanical Engineering

In the intrinsically shape-shifting field of engineering, the development of 3D printing and computer-aided design (CAD) is transforming the substance and scope of mechanical design. These cutting-edge technologies aren't just cool-sounding tools, but catalysts for change, leading to unparalleled precision and ushering in a new era of accelerated innovation.

By examining the way CAD and 3D printing work, specifically CAD modeling software and additive manufacturing, we can not only understand their role in reshaping mechanical design as we know it, but also imagine how these technologies will revolutionize and rescale the field of engineering in the years to come.

Understanding CAD and 3D printing: beyond the acronyms

CAD, short for computer-aided design, refers to the use of computer software to create, modify, analyze or optimize a digital model. Integrating CAD into mechanical design simplifies the design process by allowing designers to visualize the final product in a detailed, two or three-dimensional context, enabling better decision making even before a physical prototype is created.

This increases the designer productivity of designers, reduces the risk of errors, improves the quality of the designs themselves and creates a large, experimental manufacturing database.

CAD + 3D printing = A fusion of imagination and science

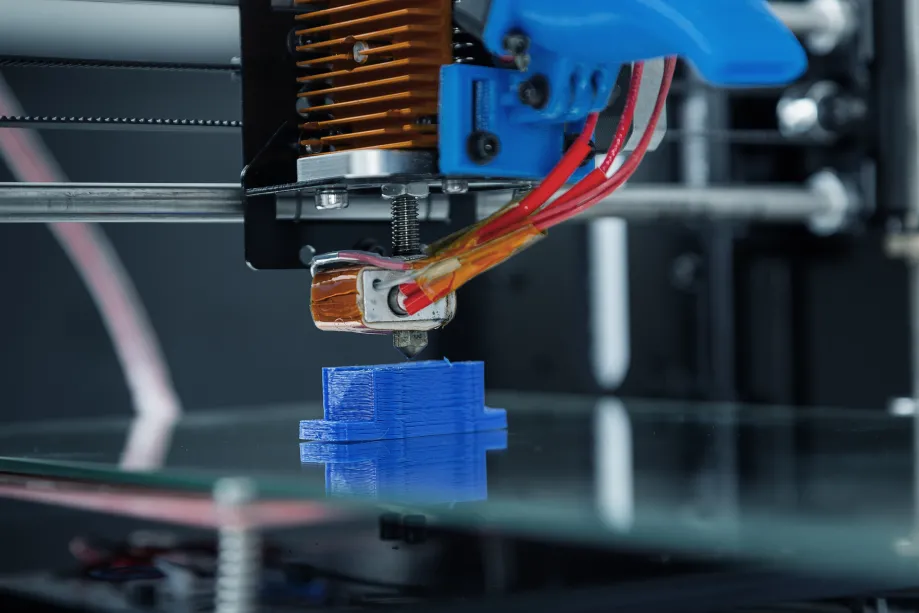

3D printing or additive manufacturing complements this creative process as it transforms these virtual models into physical realities by layering materials to construct three-dimensional objects. STL files, short for stereolithography, is the main CAD file format used for additive manufacturing design projects, providing detailed specifications for these unique creations. CAD files are then converted into coded instructions for the printer using what is known as slicing software.

Reshaping mechanical design through innovation and customization

CAD files and modeling software play a central role in turning concepts into tangible products.

The user-friendly interfaces of modern CAD software like SOLIDWORKS, combined with advanced features such as generative design, enable the creation of models that accurately reflect the size and complexity of real objects no matter how large or small.

Free, cloud-based CAD platforms further democratize design, offering scalable, creative environments that cater to all industry profiles, from individual entrepreneurs to large industrial organizations. They provide a unified environment that facilitates communication and real-time collaboration, enables the secure sharing of data, and gives access to a range of tools that streamline the design process.

Parametric modeling

Parametric modeling, a feature of modern CAD software, breaks yet another barrier. Using a digital calculation method to manipulate geometry, the designer creates a set of parameters, or rules, that define the shape, size and behavior of an object. These parameters can then be adjusted to explore a wide range of different designs without having to redraw a design every time one of the design’s dimensions change. Designers can quickly edit and change parts of the design, making design iterations more efficient and intelligent.

Parametric modeling is crucial for the development of innovative, practical and sustainable models in various fields such as architecture, jewelry, furniture or fashion. In architecture, for example, it enables the creation of complex shapes and structures adapted to the specific requirements of a project and/or environment.

Customization at its peak through 3D printing

3D printing is a driving force for innovation in mechanical design. It enables high levels of complexity, detail and customization at low cost and encourages experimentation that would be impossible or prohibitively expensive with existing building techniques. Its versatility in design and application, from the manufacture of intricate, high-strength aerospace components to the production of bespoke prosthetics in the medical field, demonstrates a blend of speed, precision and reliability that is difficult to achieve with conventional manufacturing methods.

Maximizing efficiency while minimizing costs

The fusion of CAD and 3D printing goes beyond innovation by drastically reducing time to market. While CAD software allows for quick changes and iterations, 3D printing enables rapid prototyping and manufacturing, shortening traditionally extensive production processes.

This overall efficiency leads to significant cost savings in materials and production time, making high-quality design more accessible and achievable. 3D printing also makes it possible to store certain spare parts in a virtual warehouse and produce them on demand, reducing inventory costs, especially for smaller production runs.

Integration of artificial intelligence

The integration of AI into computer-aided design promises to revolutionize manufacturing and product design processes considerably. This is mainly due to:

- The ability of AI to quickly create CAD solutions that take into account all relevant factors, including material properties, manufacturing constraints, user needs and performance requirements.

- Advanced techniques such as deep learning and computer vision that enable AI to derive insights from existing designs and natural phenomena.

- AI's ability to analyze vast amounts of complex data and predict outcomes.

The results are shorter development times, fewer errors and lower costs, even for complex projects or tight deadlines, making the adoption of CAD and 3D printing more widespread.

Conclusion: Designing the world of tomorrow, today

Supported by advances in AI, CAD and 3D printing are not only pushing the boundaries in terms of manufacturing efficiency and product innovation, but also opening doors to unprecedented levels of creativity and possibilities that extend beyond the realm of mechanical engineering. Niche materials for 3D printing are gaining traction with a wide range of users: scientists are already experimenting with 3D bioprinting, chefs are trying their hand at 3D printing food and contractors are looking into 3D printing concrete.

For designers and engineers, the use of these technologies is not an option, but a necessity to stay at the forefront of mechanical engineering, the future of which is being designed now, in three dimensions.