DELMIA Advanced Milling

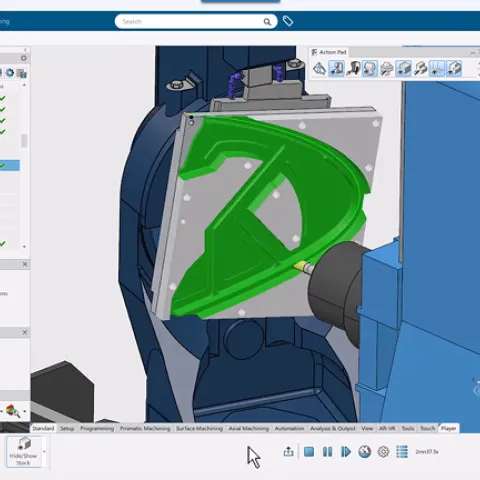

Full Milling solution for 2.5-Axis, 3-Axis & 5-Axis, including Machining with Robots

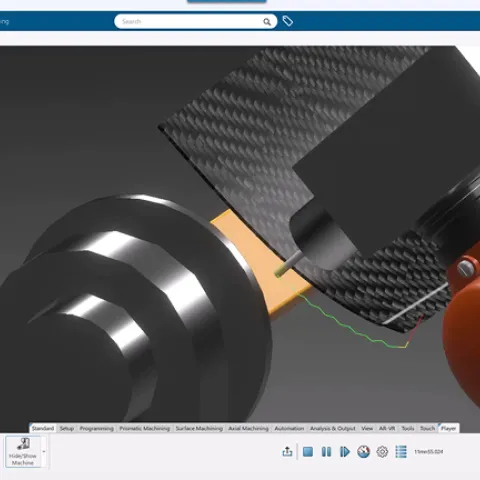

High-Performance Multi-Axis Machining

Accelerated Programming with Reusable Knowledge and AI

Machining with Robot Programming

End to end programming efficiency and risk reduction

Expert Guidance & Resources for a Smooth Start

- A certified partner will be available to help you with personalized support

- Get online learning resources through our Get Started page

DELMIA Advanced Milling Functionalities

Prismatic Machining

High-Speed Rough Milling

3-Axis Milling & Rework Area

Advanced Finish Milling

5-Axis Roughing

4- and 5-Axis Milling

Machining With Robot Programming

AI-Based Predictive Operation

AI-Based Toolpath Parameter Optimization

Single- & Multi-Stylus Probe Operations

Wire EDM Programming (2-Axis and 4-Axis)

Laser and Water Jet Cutting

DELMIA Advanced Milling

- Advanced Multi-Axis Programming: Enables creation and validation of 2.5- to 5-axis milling programs for complex, multi-cavity parts with high automation and efficiency.

- Comprehensive Toolset: Includes features for workpiece setup, tool assembly, simulation, material removal, and NC code generation.

- Collaboration & Knowledge Reuse: Provides access to machining data, supports teamwork, and captures enterprise expertise for future use.

Highlights

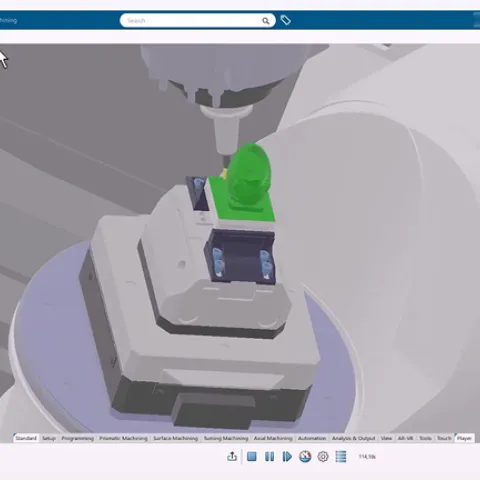

DELMIA Advanced Milling immerses users in a realistic environment. A toolpath creation wizard and context-based menus enable quick 3D setup and NC tool path creation. Traffic lights signal if parameters need to be defined. If a user clicks on a help icon while editing a parameter, an image describing the parameter pops up in the panel. Users can quickly organize programs in the activities process tree using copy-and-paste functions. Tool changes and machine rotations are automatically generated and can be visualized in the activity process tree.

Allows users to manage CNC machines, accessories, tools, and tool assemblies. These resources can be retrieved through standard PLM search capabilities using relevant machining attributes, and instantiated in a manufacturing cell. Users can clearly see the impact of changes on the definition of objects such as parts or cutting tools, across all NC processes and programs. DELMIA Advanced Milling supports default or customized representation of cutter and tool assemblies used for verification, simulation with material removal, and collision checking.

Automatically recognizes the prismatic machining features of the product design, significantly reducing toolpath programming time. A manufacturing view of the design part is generated with all the drilling and milling features that are to be machined. Through this embedded feature-recognition technology, DELMIA Advanced Milling enables toolpath programming for geometrical-machined, feature-creation design parts—even those with no design feature specifications.

The tool path can be optimized for high-speed or point-to-point machining and for a full set of axial operations from standard drilling to complex boring and chamfering. Probing operations are very flexible and can be customized with associated user parameters. DELMIA Advanced Milling extends the 2.5-axis capabilities by offering a best-in-class 4-axis pocketing operation that includes a variety of strategies, island management and user-defined lead angle on the tool axis for better cutting conditions. This operation also supports non-cylindrical and non-conical surfaces and revolution surfaces going beyond 180 degrees.

DELMIA Advanced Milling offers a full set of high-end 3-axis milling strategies from roughing to finishing, such as sweeping, Z-Level, contour-driven machining and curve machining. Users can select a roughing strategy—such as back-and-forth, helical, concentric or part-offset—based on the material being machined and the shape of the part. It takes tool assemblies into account during computation to generate a collision-free tool path. As roughing operations are defined, the in-process part is computed and used as the starting point for the next operations. Users can then create a new roughing operation with a smaller diameter tool. This tool path is automatically generated based on material that remains from any previous operation, including roughing. The Advanced Concentric Milling strategy controls the radial engagement of the cutting tool to maximize the efficiency of the machine while protecting the cutter. DELMIA Advanced Milling provides a full set of multi-axis milling strategies, including spiral milling, tube machining, curve following, flank contouring, helix, and interpolated axis along an isoparametric surface.

DELMIA Advanced Milling allows users to simulate, validate, and program wire Electrical Discharge Machining (EDM) processes. Users can compute the wire EDM path and program the synchronization of each end of the wire to the part contours. Users can implement 2 and 4-axis programming capabilities with dedicated wire EDM strategies, visualize and validate their program strategy, and then produce the machine code to be used in the real machine. As with all DELMIA Machining applications, users can save and reuse best practices by creating the wire EDM paths, storing them in a template, and then reusing the same strategy on other parts to be machined.

Adjusting parameters in the machining operation, fine-tuning the approach/retract macro, and optimizing path sequencing are achieved almost instantaneously in DELMIA Advanced Milling with this unique technology. Built on the 3DEXPERIENCE® platform, DELMIA Advanced Milling offers complete associativity with design tools, product engineering, manufacturing processes, and resources. Users are automatically alerted to product design changes. They can quickly assess their impact on the machining process and easily update the toolpath program.

DELMIA Advanced Milling can compute the volume of gouges in the workpiece, making it easier for users to prioritize and process these gouges in machining programs. Near misses, within the user-defined safety distance, are also identified, and multiple tool change locations are also supported for a more accurate simulation of the machine motions. The simulation context, saved in the 3DEXPERIENCE platform, allows the user to organize their review most conveniently, and it also ensures traceability of the validated task. It allows users to program, optimize and validate the machining most efficiently. DELMIA Advanced Milling lets NC Programmers identify toolpath errors earlier in the process and shortens programming time.

Benefits

The wide range of operations and strategies helps programmers create toolpath programs that minimize non-value-added motions. Programs include high-speed machining features and reduced overall machining cycle time. DELMIA Advanced Milling takes in-process parts into account to generate collision-free tool paths.

Its realistic presentation of 3D enables programmers to create optimized NC programs in the manufacturing context: NC machine, cutter, tool assemblies, NC accessories and other elements. This provides a better understanding of the manufacturing cell and ensures that the tool path and machining strategy take the tool’s physical environment into account. It reduces the risk of unexpected issues and production delays.

Users can quickly author and edit NC programs for multi-axis milling machines. It delivers dedicated, multi-pocket operations for efficient machining of 80 percent of the part with a high level of automation. Powerful operations, such as Flank Contouring or Multi-Axis Curve with Interpolated Tool Axis, give NC Programmers full control for machining very specific areas and allow them to complete their jobs.

Intuitive graphic dialogue boxes, traffic light indicators for undefined machining parameters, and help icons for each parameter make the process highly efficient. Tool changes and machine rotations are automatically generated and can be visualized in the machining operation definition panel. Copy-and-paste functions help organize programs in the specification tree. Users can define and store machining processes for complex operations as dedicated templates and store them in catalogues for reuse. Enterprise IP is capitalized and recycled to make programming more efficient.

DELMIA Advanced Milling gives NC Programmers an unrivaled level of associativity between product engineering, manufacturing processes, and resources. Companies can manage concurrent engineering and manufacturing flows more effectively and shorten the design-to-manufacturing cycle. DELMIA Advanced Milling offers support for design changes and design variants, and the rapid creation of programs for families of parts. Native implementation links connect machining programs to engineering and manufacturing data, which can be used to determine which machining programs are impacted by engineering or manufacturing changes (e.g. new cutter) and whether machining data is up to date with engineering changes.

Explore Other Roles

MILLING

CAM solution for 2.5-Axis & 3-Axis milling, including adaptive concentric milling for hard material machining.

TURNING

CAM solution for 2.5-Axis milling & turning, including mill-turn and swiss turn machines.

PREMIUM MILLING & TURNING

Complete CAM solution for milling, turning and mill turn.

Customer Stories with DELMIA CAM & Machining Software

Discover how industry leaders like Sandvik Coromant, Carbomill, and Bilfit AG use DELMIA CAM software for CNC machining solutions to optimize precision and complex manufacturing challenges: