Engineering Bill of Materials

A well-defined EBOM ensures accuracy, efficiency and seamless collaboration across product development disciplines

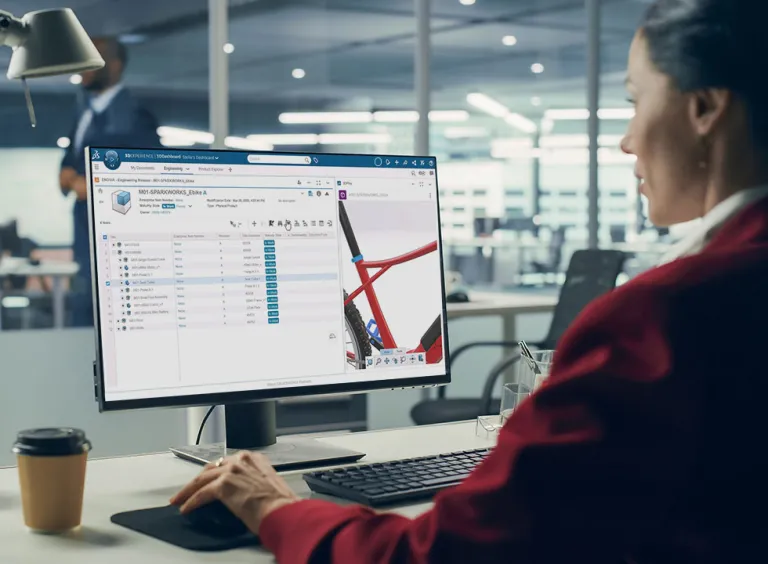

What is an EBOM?

An Engineering Bill of Materials (EBOM) is a comprehensive product recipe structured from the design perspective, originating from engineering software such as computer-aided design (CAD) and electronic design automation tools. It encompasses raw materials, components, parts, subassemblies and interrelated data layers essential for product creation. Unlike a Manufacturing Bill of Materials (MBOM), an EBOM focuses on parts as they exist in the design sense, typically listing items from an engineering standpoint.

Why EBOM is Essential for Modern Manufacturing?

EBOM is essential for modern manufacturing because it clearly defines the product’s design intent, establishing the foundation for every downstream process. In today's complex manufacturing landscape, where supply chains span continents and time-to-market is critical, an accurate EBOM is indispensable for ensuring product quality, controlling costs and maintaining a competitive edge. The importance of EBOM in modern manufacturing cannot be overstated, as it forms the backbone of Product Lifecycle Management (PLM), driving efficiency and innovation across the entire production process.

Core Pillars of EBOM

Comprehensive Component Details

List all parts, materials and assemblies with precise specifications.

Quantity Accuracy

Ensure exact quantities of each component required for production.

Design Intent Alignment

Reflect the engineering design to ensure the final product matches specifications.

Change Management

Track revisions and updates to maintain version control and consistency.

Collaboration Enablement

Facilitate communication between engineering, procurement and manufacturing teams.

Sustainability and EBOM

Drive Eco-Friendly Manufacturing Practices

An EBOM plays a significant role in promoting sustainability in manufacturing. By providing a detailed view of product composition, it enables engineers and designers to identify opportunities for using more sustainable materials or optimizing resource usage. EBOM also supports efforts to improve product recyclability and reduce waste by facilitating the tracking of materials and components throughout the product lifecycle management.

Use Cases: EBOMs

Product Development & Engineering

The EBOM acts as a key reference for design teams, facilitating collaboration across disciplines. It helps track design changes, manage versions and assess modifications, enabling engineers to optimize product designs and drive innovation.

Manufacturing Process Optimization

An EBOM helps streamline manufacturing by providing manufacturing items that are equivalent with the engineering items. This is the first step in manufacturing, as the manufacturing engineer can now begin building the MBOM based on the information from the EBOM.

Sourcing

An EBOM also contains information on alternates, along with their qualification level, helping to shorten sourcing cycle times and ensure reliable and on-track deliveries.

Supply Chain Management

An EBOM supports supply chain management by providing a clear list of materials, allowing for more accurate forecasting and ordering. It helps negotiate better terms, reduce lead times and supports supplier diversification, leading to a more efficient and flexible supply chain.

Key Features of EBOMs

EBOM & Virtual Twin Technology

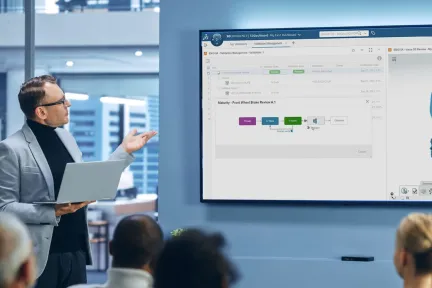

Revolutioning Product Lifecycle Management

The integration of EBOM with Virtual Twin technology is transforming PLM. Virtual Twin, a digital representation of a physical product or process, combined with EBOM, creates a powerful tool for simulating and optimizing products throughout their lifecycle. This synergy enables real-time collaboration across teams and locations, facilitating rapid design iterations and improvements.

The EBOM-Virtual Twin combination also enhances predictive maintenance capabilities, as the digital model can be updated with real-world performance data, leading to more efficient and sustainable product operations.

Customer Stories

Uncover the Value of 3DEXPERIENCE-based EBOM Creation and Management

CNBM Triumph Robotics

With several sister companies already using Dassault Systèmes’ technology, CNBM Triumph Robotics naturally chose to implement the 3DEXPERIENCE platform, adopting ENOVIA to support project management, PLM standardization and centralized knowledge banks.

The 3DEXPERIENCE platform offered a holistic solution, with diverse modules covering all aspects of our digital scenarios. This is very appealing to us.

Take the Next Step

Dive into the content below to see how PLM solutions can support your business.

FAQs- EBOM

Also Discover

Learn What ENOVIA Can Do For You

Speak with an ENOVIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right ENOVIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering.