Decoding business model transformation

As the digital revolution continues, manufacturers are finding themselves driven to pursue new, revolutionary business models.

What business models will the world of the future demand?

What is business model transformation?

"There is nothing permanent except change” – Heraclitus

Businesses like predictability and familiarity. These are qualities that enable effective planning, budgeting, and implementation.

Unfortunately, predictability is not always a quality of the real world. The real world is often characterized by volatility, unpredictability, complexity and ambiguity (what we call VUCA). This has never been more so than today, where the forces of digitalization and mass connectivity have accelerated the pace of change, ushering in new ways of working, communicating, and collaborating.

This technological transformation is precipitating an upheaval in business infrastructure and behavior no less radical than the industrial revolution. And on top of these fundamental structural changes, there have been more unexpected geopolitical shocks, most recently in the form of a global pandemic and the war in Ukraine. These can have profound consequences for business-as-usual.

“Around 80% of existing business models were already at risk,” says Florence Verzelen, Executive Vice President, Industry, Marketing and Sustainability at Dassault Systèmes. “Across the past three years, we've seen a lot of crises, all of which have impacted manufacturing business models. For example, many businesses ran on low-stock, just-in-time models,” she says. “COVID-19 and the Russian invasion of Ukraine have highlighted the fragility of these approaches.”

Curious about how other manufacturing industries respond?

Respond to today's challenges with our bespoke solutions

What does manufacturing business model transformation look like?

For businesses finding themselves cast adrift in this brave new world, old certainties are crumbling. It’s estimated that 20% of business fail in their first year, and around 60% fail in their first three. Making sure your business model is fit for the future, and capable of adapting to shocks, is therefore critical if business growth is to be assured.

The models that drive business transformation will be those that can best leverage the huge potential of digital technology to meet evolving customer demands, whilst avoiding the associated investment risks and data privacy pitfalls.

But what might these new business models look like?

1. Everything-as-a-service: At the beginning of the 2010s, platforms like Netflix and Uber came along and ripped up the rulebook for how products and services were sold. Now manufacturing is sitting up and taking note of the service economy and the rise of platformization.

“People don't want to buy products anymore, they want to buy experiences,” says Florence Verzelen. “Gen Z don't necessarily want to own a car; they want to get from point A to point B.

“For manufacturers, the experience economy demands a totally different business model. It marks a shift from CapEx to OpEx, providing a product experience rather than purely a product. And it doesn’t matter if you’re selling a car or a piece of industrial equipment, the approach is the same.”

2. Rapid product evolution: Products are changing. They are increasingly digital and connected, throwing up new design and manufacturing complexities. They are utilizing new materials and production techniques, like additive manufacturing. And most of all, they are more responsive to the demands of a buying public. This not only means more personalized and customized, but more ethical and sustainable products and services.

“85% of consumers now prefer to purchase an experience or a product or a service that is sustainable,” says Florence Verzelen. “This means that you have to incorporate sustainability right across your value chain, from design, to manufacture, to logistics, to how you recycle products at the end of their life. This then allows us to extend product lifetimes, adding multiple lives to the same initial product through improved refurbishing, recycling, and reuse techniques. It’s about embedding circular practices.”

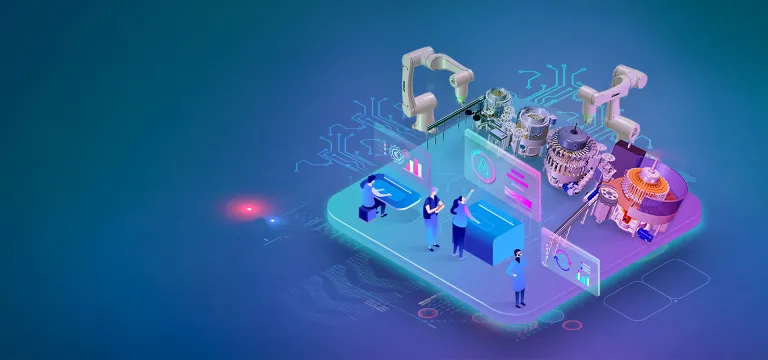

Data-powered manufacturing: The forces of the new economy aren’t just changing what is made; they are also changing how manufacturers go about making it. In particular, the explosion of data generation and manipulation in factories is ushering in a new era of industry transformation and operational optimization, radically changing how those factories are managed.

From predictive maintenance to the integration of new forms of production, new factories must be reconfigured to take advantage of the opportunities that the data revolution provides and embrace new manufacturing models.

Substantially changing the way you operate, of course, brings its own risks. Moving away from established revenue models can mean you are suddenly competing against small, agile, innovative disruptors, whose low cost base and tech-driven approach enables them to adjust to shifting customer demands more easily.

Embracing digital technology and digital model transformation also potentially increases the threat of cybercriminals and hackers. From criminal gangs to nation-state players, cyberattacks are increasingly well-resourced and highly targeted. Thriving and surviving in the new economy and creating a resilient business model means keeping one eye on threat vectors and ensuring that cybersecurity considerations are embedded in strategic planning.

Behind all of this is a more existential threat – climate change. Extreme weather events are forcing factory closures and disrupting supply chains. The sustainability imperative is driving new legislation and shifting consumer demands. Balancing business innovation against business resiliency necessitates factoring in the wide-ranging impact of this new reality.

How do you create a transformation plan?

So what can businesses do amid such seismic shifts to encourage business resiliency? How can business model innovation be effectively pursued? Well, innovation, from sustainable innovation to commercial innovation, increasingly means making the most of your data.

This starts with collecting, standardizing, and analyzing it in a way that means it can be effectively utilized. From supply chain to sales, design to distribution, manufacturers produce huge amounts of data. Having all this information in the right state enables businesses to make decisions far beyond next quarter’s budget, and allows for successful business model innovation.

“The most logical next step in using data to manage this scale of transformation is the virtual twin,” says Florence Verzelen. “Take your products, for example. If you have a virtual twin of your product, you can optimize it at the design stage, boosting its quality and durability – and help reduce its environmental footprint. But you can also model the whole post-sales life of that product, looking at how it might need to be maintained, how its components could best be recycled when it has reached its end of life, and what its second or third lives could be.

“The value of virtual twins also extends into your operations. If something goes wrong in your supply chain, for instance – say if one of your suppliers comes and says, ‘we’re out of semiconductors’ – you can turn to your virtual twin and experiment with new models, risk-free, and use that information to find new suppliers or logistics arrangements and get your operation back up and running.”

But what is an example of how we can respond to business model transformation?

"What does this approach to business model transformation look like in practice? Let's look at an example,” Florence Verzelen continues. “Consumer electronic goods have many challenges. Having the virtual twin of your computer allows you to create a computer that is sustainable, or circular, by design.”

“What does that mean? It means that if I'm doing the design of my computer in the virtual world and working on the virtual twin, I'm able to plan for the second, the third, the fourth life of each component of my computer and make sure every part is circular.”

If businesses are going to thrive in a world of metamorphosing physical and commercial realities, they need to be clearsighted about the landscape they are in and about the changes they need to make. Change is inevitable.

You have to incorporate sustainability right across your value chains, from design, to manufacture, to logistics, and to how you recycle products at the end of their life

Other Trends

Discover more with our Manufacturing Industries

- Aerospace & Defense

- Consumer Packaged Goods & Retail

- Home & Lifestyle

- High-Tech

- Industrial Equipment

- Marine & Offshore

- Transportation & Mobility

Bridge the gap between the virtual and real world to accelerate from concept to operations.

To successfully launch satellites into orbit, New Space companies must speed up innovation in satellite technology. How can they deliver right the first time?

The New Aerospace Pioneers of the 21st Century

Discover how the 3DEXPERIENCE® platform drives innovation in the industry with CPG solutions for design, simulation and AI-driven forecasting.

Simplify and accelerate innovation to create more valuable consumer experiences.

Shorten the stand-up time of configurable, sustainable data centers through virtual twin experiences.

Digitalize manufacturing to deliver made-to-order innovation.

Leverage the 3DEXPERIENCE platform for greater field operations efficiency, after-sales services and success in the industrial equipment scene.

Accelerate the sustainable transformation of the Marine & Offshore industry.

Driving vehicle innovation toward the mobility of the future

Digital optimization can accelerate eDrive development towards a profitable future

THE WORLD NEEDS MANUFACTURERS

A MANIFESTO FOR CHANGE