Titan LATAM

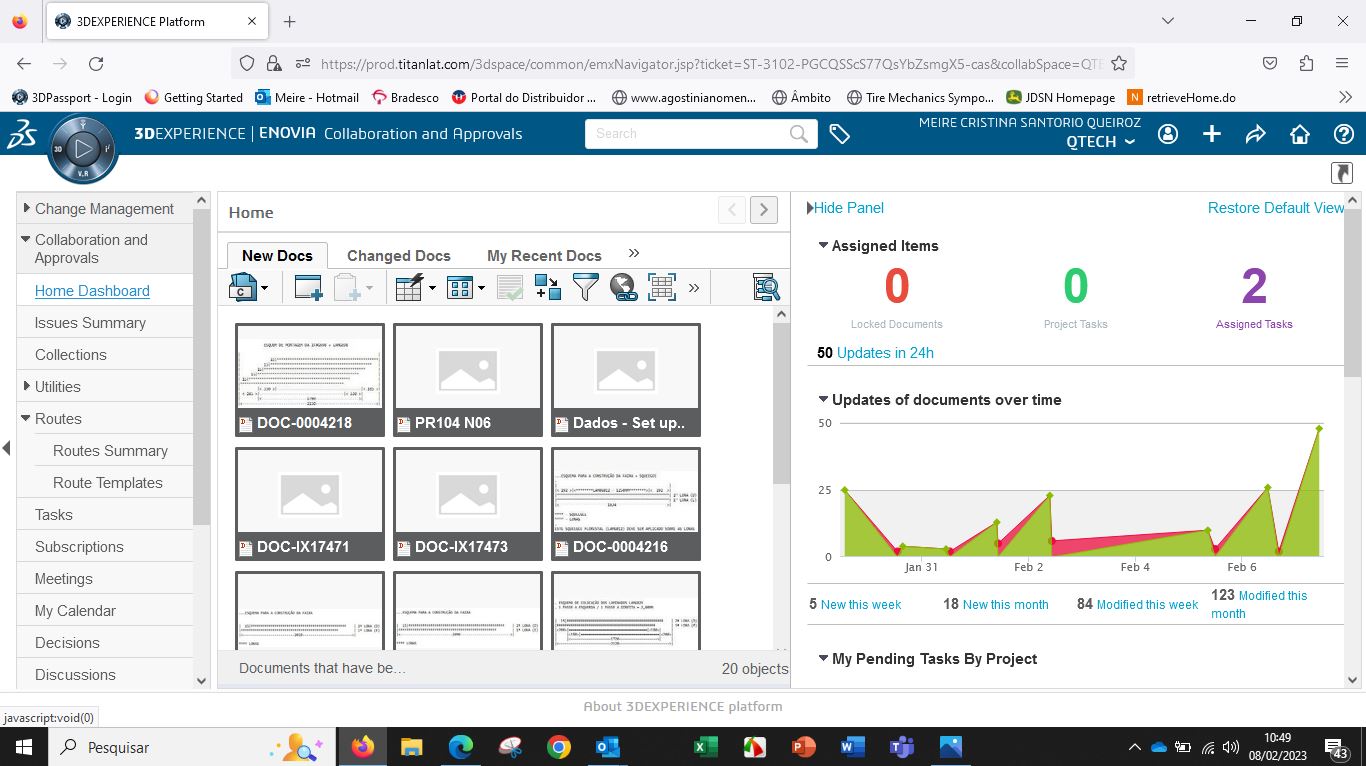

Titan LATAM chose Dassault Systèmes’ SmarTyre industry solution experience on the 3DEXPERIENCE platform, including ENOVIA for collaboration and intelligence tools and SIMULIA for realistic simulation.

Keeping agribusiness innovative and growing

Across fields, forests and processing plants, heavy agricultural equipment must tackle challenging loads, harsh weather conditions and demanding terrain. It could not do that without reliable, specially designed tires. Titan LATAM specializes in engineering and manufacturing tires that keep innovative agricultural machinery moving, while working to ensure a positive impact on the environment and local communities. An example of one of Titan’s innovations includes its Low Sidewall (LSW) technology that reduces swaying at high speed travel, and significantly reduces risk of power hopping and soil compaction.

“The technology involved in agriculture today is enormous and it’s moving at a very high speed,” said Edson Tebaldi, managing director of Titan LATAM, which supplies agricultural tires in Latin America, Europe and Africa. “Operational speed in the market is Titan’s great differentiator. We continually focus on market trends, new product technologies and working closely with our customers to accurately understand their needs. In 10 years, for example, we have developed more than 400 new tires which are approved for sale as original equipment.”

Half of all the tractors produced in Brazil have Titan tires. Titan acquired its factory in São Paulo, Brazil, from Goodyear in 2011. Since then, the company has continually invested in the plant and in 2023 it plans to increase production capacity at the facility by a further 10%. To support that growth, it needed a business innovation platform that would enable collaboration between all its departments and faster product development.

Titan’s existing legacy IT system could no longer support the growing business, as it could not be updated to meet their needs. It was essential to integrate the company’s enterprise resource planning (ERP) system and safely migrate 25 years of product development data. After discussing its requirements with Multittech, a business partner of Dassault Systèmes, Titan selected the SmarTyre industry solution experience on the 3DEXPERIENCE® platform including ENOVIA for its collaboration and intelligence tools and SIMULIA for realistic simulation and structural analysis.

“Our greatest challenge was to find a solution that would meet the requirements not just of our engineering area, which includes product and composite development, but also of the factory floor,” said Meire Santorio, senior technology and quality manager at Titan LATAM. “When we started studying and understanding our processes and the 3DEXPERIENCE platform, there was an incredible match. We had really found the solution to take our entire legacy system into the platform.”

Fortunately, choosing Dassault Systèmes was a success story. We really had an excellent interaction in this process, where we were able to transform this whole idea of how to make this technical systems network within the company and we turned it into an action plan.

Simplifying a complex project

This was a challenging migration project, but Multittech’s support and the 3DEXPERIENCE platform proved a winning combination. It took approximately one year to implement and customize the platform and securely migrate all the legacy data so the entire system could go live at once. For Titan, it was crucial for the factory to continue working as normal throughout the implementation because the company was engaged in major product development and production projects.

“We had a great mass of different data and platforms that we had to migrate to the new system,” said Ricardo Teixeira, IT manager at Titan LATAM. “Multittech provided a well-assembled team, with an experienced project manager who was instrumental to the success of the project. Their support team was in a different time zone, but they adapted to our time zone to work with us, meet our needs and make the migration much easier.”

“Fortunately, choosing Dassault Systèmes was a success story,” Tebaldi said. “We really had an excellent interaction in this process, where we were able to transform this whole idea of how to make this technical systems network within the company and we turned it into an action plan.”

Harmonized processes

The day-to-day processes are much easier for Titan’s workers with a single platform where it can connect and automate processes.

“There were numerous challenges before 3DEXPERIENCE and we have eliminated them with the new platform,” said Roberta Rodrigues, process and quality manager at Titan LATAM. “As well as needing to safely migrate 25 years of tire history, we also had manual processes that were parallel to our previous specification system. This required the team to work on spreadsheets manually, causing rework and even errors as they didn’t have integration with the company’s systems.”

Titan’s historical process parameters could not be revised using its old system. The 3DEXPERIENCE platform enables the team to access and revise those parameters in one place.

As an example, tracking changes in the extruder’s temperature zones was not possible before, but now the changes are registered with the revision number which helps with process traceability.

“With the 3DEXPERIENCE platform, we can revise process parameters and have better control of any changes to them, regardless of the bill of materials,” Rodrigues said. “In my area this was a significant gain. The process got faster. We started to insert process parameters within the platform and eliminated all the manual and parallel processes in spreadsheets and other means of control.”

Faster product development

The 3DEXPERIENCE platform is much more user-friendly than Titan’s previous system. As well as being faster to work with, it brings greater capability to register raw materials, components and finished products. This enables Titan to develop more products more quickly, and make changes where and when necessary for continual improvement.

“We have gained a lot with ENOVIA and the 3DEXPERIENCE platform in terms of engineering and product development, when compared to our old specifications system,” said Ricardo Karasz, product engineering manager at Titan LATAM. “One great impact was the ease and agility the platform provided to create the product itself. As soon as people started to work with the platform, we could immediately see the gains we would achieve. In the last two years, we have gained agility and ease in consulting specifications. We have full control of any product review, from raw materials to components and the finished product.”

ENOVIA also enables Titan to create and maintain a complete, accurate and up-to-date bill of materials which is linked to Titan’s ERP and to its shop-floor manufacturing execution systems and process specifications. By integrating all its data within a single platform, Titan experiences big gains in efficiency and productivity.

“We have seen a productivity increase of around 15% in product development,” Santorio said. “For example, for a relatively simple project the time between development and product launch used to be around four months. After one year of using the 3DEXPERIENCE platform, we had reduced that time by around 15%, with gains mainly in the creation of the bill of materials and the generation of information to the ERP and for the shop floor.”

Virtual testing for ensured accuracy

Titan also takes full advantage of the 3DEXPERIENCE platform’s powerful 3D simulation capabilities with SIMULIA.

“Virtual testing is very important,” Karasz said. “In addition to reducing costs and scenarios, it reduces time, which benefits both the manufacturer and the end customer. When we design a product, we imagine various situations in the field and there is no way we could test the tires in all these situations. Simulation allows us to virtually test performance in those scenarios and quickly make improvements, instead of waiting for the results of physical testing in the field.”

Using SIMULIA’s simulation technology on the platform for structural analysis helps Titan to identify any changes before the tire goes into production, for example, in designing and engineering the right tools for the manufacturing process.

“When we develop tooling for a new product, the tire dimensions are very important,” Karasz said. “Using simulation, we can include all the parameters that are important and necessary for us to understand the three-dimensional tire. We already have successful cases where the tire, after being developed, replicated exactly what we had put in the simulation. With 3DEXPERIENCE, we end up not making so many prototypes and throwing them away.”

Ready for the future

The agriculture market in Brazil uses less than 20% of its territory, and yet feeds more than 1 billion people worldwide. Supported by the 3DEXPERIENCE platform, Titan is ready to expand its role in Brazil’s burgeoning agribusiness sector.

“Brazil will be even more important to the world regarding agribusiness in the coming years, and Titan will continue to invest in Brazilian agribusiness,” Tebaldi said.

“As the market leader in agricultural tires, Titan has innovation in its DNA,” Santorio said. “The 3DEXPERIENCE platform brings all the engineering tools that will help this innovation process. Titan’s expansion and the growth of our agricultural business is totally linked to what the platform provides to support this engineering and manufacturing development.”

Discover more about the SmarTyre industry solution experience.

Focus on Titan LATAM

With more than 100 years of experience in the North American market, Titan International has 6,000 employees worldwide and selling operations in 85 countries. In Brazil since 2011, when it acquired Goodyear's agricultural business unit, Titan Tires produces high quality, resistance, performance and durability tires for vehicles such as trucks, conventional vans and a wide range of agricultural, forestry and off-road vehicles. It owns a manufacturing plant of approximately 120,000 square meters located in the heart of São Paulo city in Belenzinho district, employing approximately 1600 direct and indirect workforce.

Headquarters: West Chicago, Illinois

For more information https://www.titanlat.com/

Focus on MULTITTECH

MULTITTECH is a Brazilian company that believes in productivity and performance gains through the development of high value innovative products and solutions. Due to their qualified team, they can offer digital and innovative solutions to several industries such as: aerospace & defense, transportation & mobility, packaging, energy & materials, railway, agricultural and industrial equipment.

Headquarters: Holambra-SP, Brazil

For more information: www.multittech.com.br