Spirit AeroSystems

Spirit AeroSystems, a manufacturer of aerostructures, enhances production quality with Dassault Systèmes’ Build to Operate and Ready for Rate industry solution experiences, including the DELMIA and CATIA applications.

Augmented Reality in Manufacturing Transforms Quality

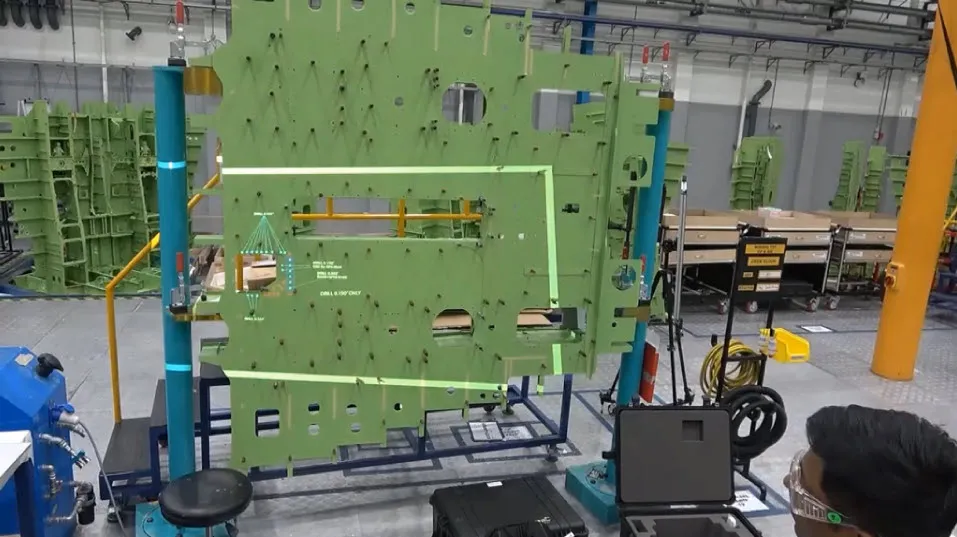

There’s a new way to build aircraft parts with ultimate precision thanks to augmented reality (AR). In Spirit AeroSystems’ manufacturing plants, mechanics rely on AR projections to assemble fuselage sections with pinpoint accuracy. Digital overlays highlight exact drill holes, bracket placements and fastener locations, guiding them step-by-step through assembly. Technicians then use tablets to map digital guidance onto completed aerostructures. Following clear visual cues, they quickly detect misalignments, anomalies or missing parts before the aerostructures leave the facility.

Spirit AeroSystems, a major US supplier of aerostructures for commercial, defense and business aircraft, is putting this technology into action, using Dassault Systèmes’ DELMIA Augmented Experience to transform mechanical assistance and digital inspections. Smart factory technologies now are embedded into its production lines as part of a broader effort to eliminate errors and improve efficiency. AR guides workers at every stage, making production more precise and seamless than ever before.

“Safety, compliance and quality are the foundations of our manufacturing system,” said Sean Black, SVP, chief technology officer and chief engineer at Spirit AeroSystems. “We continue our journey to embed quality into every step of our manufacturing process and foster a culture of continuous improvement. This approach ensures that every component meets strict quality standards and contributes to the highest levels of safety in the industry.”

Building Quality into Every Production Step

To meet growing demand for precision from its aircraft manufacturer customers, Spirit AeroSystems needed a way to guarantee that every component is built right the first time, without defects slipping through. Instead of relying on traditional inspection methods that catch issues after production, the company embeds quality detection directly into its manufacturing workflows.

“We needed a new approach; traditional methods wouldn’t get us to where we wanted to go,” said Sivakumar Balasubramanian, vice president of Manufacturing Engineering and Digital Operations at Spirit AeroSystems. “The solution had to be scalable, seamless for our customers, and ensure quality at the point of assembly. These factors guided our decision to implement DELMIA Augmented Experience.”

Today, DELMIA Augmented Experience plays a critical role in Spirit AeroSystems’ manufacturing approach, maintaining strict quality standards and precision at every stage of production. With the AR mechanical assist solution, mechanics receive step-by-step instructions directly on the part they’re working on, helping them work quickly and accurately. On the inspection side, the AR digital inspection solution lets technicians check for issues immediately. It overlays 3D computer-aided design (CAD) models on the parts, so they can identify any problems without flipping through manuals. This cutting-edge approach enhances quality control without impacting production efficiency.

“Before, mechanics and inspectors had to walk to a computer, pull up engineering data, work instructions and specifications, then return to their task,” said Lalitha Sivanesan, senior manager and chief architect, Advanced Manufacturing Development, and distinctive capability leader, Engineered Factory at Spirit AeroSystems. “With DELMIA Augmented Experience, that information is projected or augmented directly onto the product from CATIA, eliminating the need to search for details. It streamlines their workflow and cuts the time it takes to complete each task.”

Integrating AR has reduced assembly errors, improved first-time quality rates and boosted worker confidence in the inspection process. Now, workers can rectify potential issues before they escalate, resulting in a smoother and more reliable production cycle.

“Since deploying this, we’ve seen a significant reduction in assembly defects,” Sivanesan said. “Our focus was to integrate this into the production system and establish a full closed-loop process.”

DELMIA Augmented Experience is a key enabler of our digital modernization strategy. By integrating augmented reality and virtual twin technology in our operations, we’re creating a more seamless product lifecycle. This improves accuracy, increases quality, reduces rework, and enhances collaboration across our teams.

Integrated Manufacturing Operations and Quality Assurance

Spirit AeroSystems took a structured approach to implementing DELMIA Augmented Experience. It began with a small trial, testing the technology for mechanical assistance in a high-labor factory to gauge its effectiveness. Utilizing the projection system for accomplishing the assembly and fabrication needs of this facility – with quality and on-schedule – was key to proving out the capabilities of DELMIA Augmented Experience before implementing in even larger plants with more complex assembly lines.

“This [approach] allowed us to evaluate how the AR solution could function in a real-world production environment without full system integration,” Sivanesan said.

Encouraged by the improvements in efficiency and accuracy from the AR mechanical assist solution, the company scaled its use of augmented reality to encompass digital inspections. By integrating the technology with its manufacturing operations management system DELMIA Apriso, Spirit AeroSystems created a seamless and data-driven approach to quality assurance.

“Planning launches DELMIA Augmented Experience and pulls configuration content needed for the inspection process,” Sivanesan said. “If any anomalies are detected, the system automatically feeds them back into DELMIA Apriso to trigger corrective actions. This eliminates manual data entry errors and seamlessly transfers information between systems. As we train the solution’s AI model, we’ll further enhance precision and reduce manual effort.”

Because DELMIA Apriso and DELMIA Augmented Experience integrate easily together, Spirit AeroSystems implemented AR capabilities quickly without disrupting existing workflows. Infosys Limited, a long-term Spirit AeroSystems and Dassault Systèmes partner, stepped in to help with the integration – fast-tracking the build of an integrated enterprise landscape – with DELMIA Augmented Experience, DELMIA Apriso and SAP.

“DELMIA Augmented Experience met our key criteria for integration,” Balasubramanian said. “With DELMIA Apriso already in place, we were able to bring the solution to the shop floor quickly. This seamless connection accelerated deployment and ensured the technology became a natural extension of our production system.”

Hands-on Training Accelerates Adoption

The shift to AR in Spirit AeroSystems’ assembly and inspection processes isn’t just about adopting new technology; it’s about empowering the workforce. Spirit’s strategy focused on getting workers comfortable using the solutions and encouraging them to see how they could make their jobs easier as well as contributing to higher quality standards. By embedding AR into everyday workflows, Spirit fostered a culture where workers actively use the technology to identify issues in real time, correct them immediately, and take greater ownership of the final product.

“The adoption of DELMIA Augmented Experience was met with open arms,” said Thanh Nguyen, AMD engineer and project management, Advanced Manufacturing Development at Spirit AeroSystems. “Workers were excited to see digital technology actively improving inspection processes on the shop floor. Previously, they had to manually inspect components by switching between a computer and printed specifications. Now, they have these advanced AR capabilities at their fingertips.”

Dassault Systèmes provided both hands-on and classroom training so that workers were confident using the AR solutions. Together with Infosys and the team at Spirit AeroSystems, they tested different AR-compatible devices and refined the system for real-world use. Spirit AeroSystems also developed subject matter experts within its factory to train others, creating a ripple effect that accelerated adoption. By equipping these experts with the necessary skills, the company established a structured training approach that improved efficiency, reduced learning curves, and enhanced visual inspection capabilities on the shop floor.

Infosys helped build the design and work-instructions data in the required format for DELMIA Augmented Experience consumption at scale. A standardized, automation-enabled and quality-controlled approach to feeding the right data in the right format was critical in building the operations team’s confidence in every job executed using DELMIA Augmented Experience.

“We were able to really move the needle with our partners, Dassault Systèmes and Infosys, to get us to that next level of development and create a culture of continuous learning and improvement,” Sivanesan said. “With a very talented Spirit cross-functional team, we pulled this altogether in just six months, from the time we started the pilot to full-scale production.”

Connected, Data-driven Aerospace Manufacturing

DELMIA Augmented Experience gives Spirit AeroSystems a powerful way to reassure customers about product quality. By providing a digital record of inspections, the company offers clear, verifiable proof that every component meets the highest standards, strengthening customer confidence in its manufacturing processes.

“Our customers have seen the success of DELMIA Augmented Experience in our plant in Wichita, Kansas, and they’ve asked us to expand its use across all our product lines where similar challenges exist,” Balasubramanian said.

For Spirit AeroSystems, augmented reality is a key part of a broader strategy to create a connected, data-driven manufacturing ecosystem. In the longer term, by integrating AR with virtual twin technology, automation and AI, the company is laying the foundation for future innovations in aerospace production and setting new industry standards for quality and precision.

“DELMIA Augmented Experience is a key enabler of our digital modernization strategy,” Black said. “By integrating augmented reality and virtual twin technology into our operations, we’re creating a more seamless product lifecycle. This improves accuracy, increases quality, reduces rework and enhances collaboration across our teams.”

Focus on Spirit AeroSystems

Spirit AeroSystems is one of the world’s largest manufacturers of aerostructures for commercial airplanes, defense platforms and business/regional jets. With expertise in aluminum and advanced composite manufacturing solutions, the company’s core products include fuselages, integrated wings and wing components, pylons and nacelles. Also, Spirit serves the aftermarket for commercial and business/regional jets. Headquartered in Wichita, Kansas, Spirit has facilities in the US, UK, France, Malaysia and Morocco.

For more information: www.spiritaero.com

Focus on Infosys

Infosys is a global leader in next-generation digital services and consulting, helping clients in more than 55 countries navigate their digital transformation journeys. With over four decades of experience in managing the systems and operations of global enterprises, Infosys expertly guides clients through their digital transformation, powered by cloud and AI. The company focuses on an AI-first approach, enabling businesses with agile digital solutions at scale and driving continuous improvement through always-on learning, transferring digital skills, expertise, and innovation.

For more information: https://www.infosys.com/about.html