Numeros Motors

India-based startup Numeros Motors adopted the Innovative Modules and Technologies solution to deliver engineering efficiencies and to support its design ambitions for reliable electric scooters

Building Durable and Reliable Electric Scooters

India’s last-mile delivery market for two wheelers is booming, and it’s on track to more than double by 2030, outpacing the global average by almost 40%. Many last-mile delivery firms are choosing to make their fleets all-electric. However, navigating India’s extreme climate and diverse terrain conditions – from the deserts of Jaisalmer to the freezing temperatures of Manali and the humid coasts of Goa – safely and easily on an electric two-wheeler can be challenging.

Shreyas Shibulal founded electric mobility startup Numeros Motors to address this gap in the market for a rugged and durable electric scooter that could deliver consistent performance for workers in India’s last-mile delivery sector. Over the past few years, a team of over 250 professionals, including 150 engineers, have been working from Numeros Motors’ 20,000-square-foot facility in Bengaluru to create the company’s first electric two-wheeler, the Diplos.

“The Diplos, including its electrical systems, batteries and structures, has been extensively tested under extreme climatic conditions — from desert-like environments to sub-zero temperatures,” said S. Soundararajan, the company’s vice president of engineering. “We have also conducted tests in coastal regions, assessing the vehicle's performance under conditions of salt exposure, rainfall, and humidity.”

The result is an electric scooter that, in line with its tagline ‘Gets it Done’, is built as reliable, safe and durable. It can be fully charged in less than four hours, offers a range of 140 kilometers and a top speed of 63 kilometers per hour. The Diplos also integrates telematics devices, offering on-board tracking and communication technology which fleet management companies can use to monitor real-time information. This includes distance, location, geofencing, theft protection and remote immobilization.

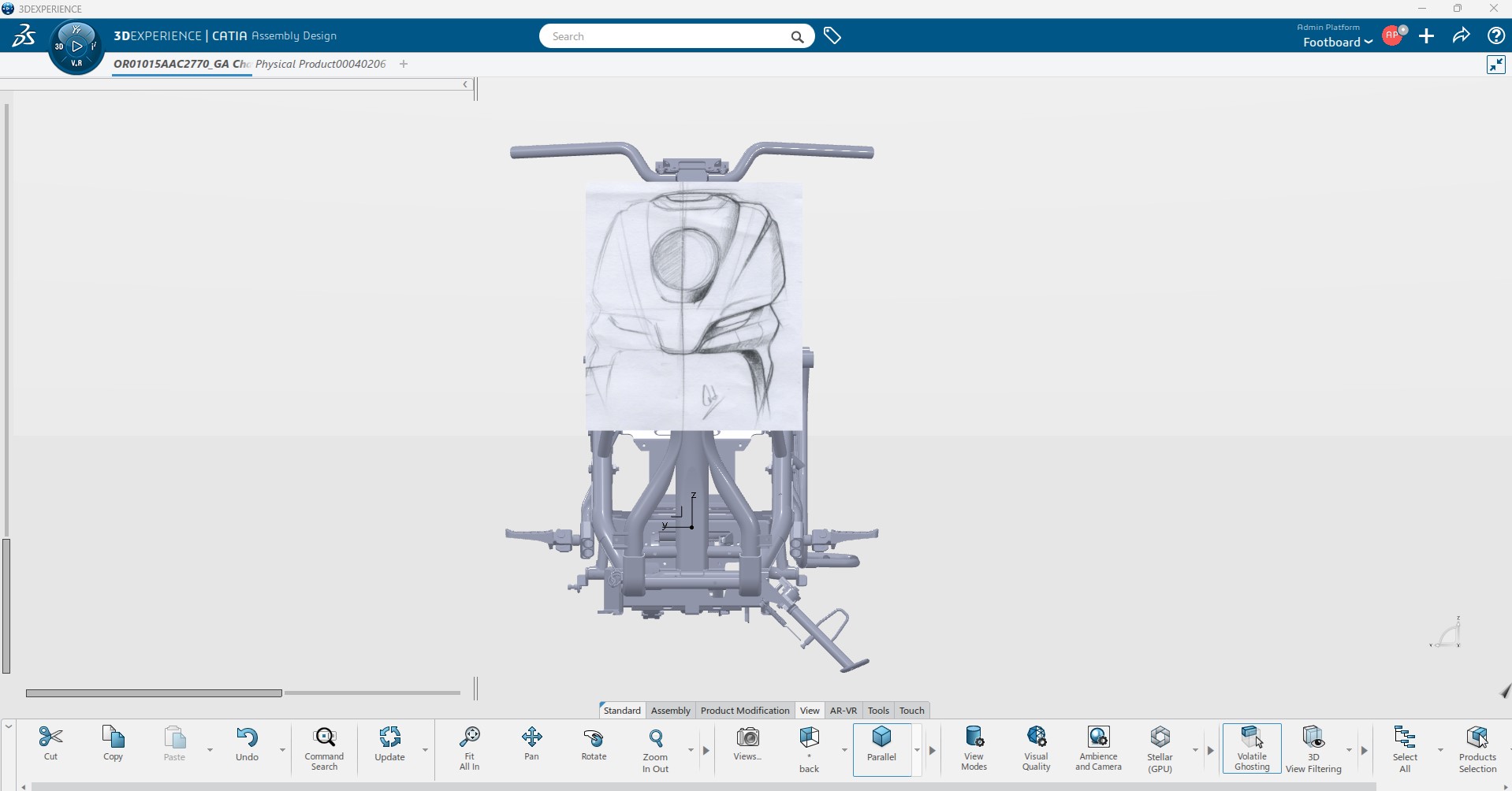

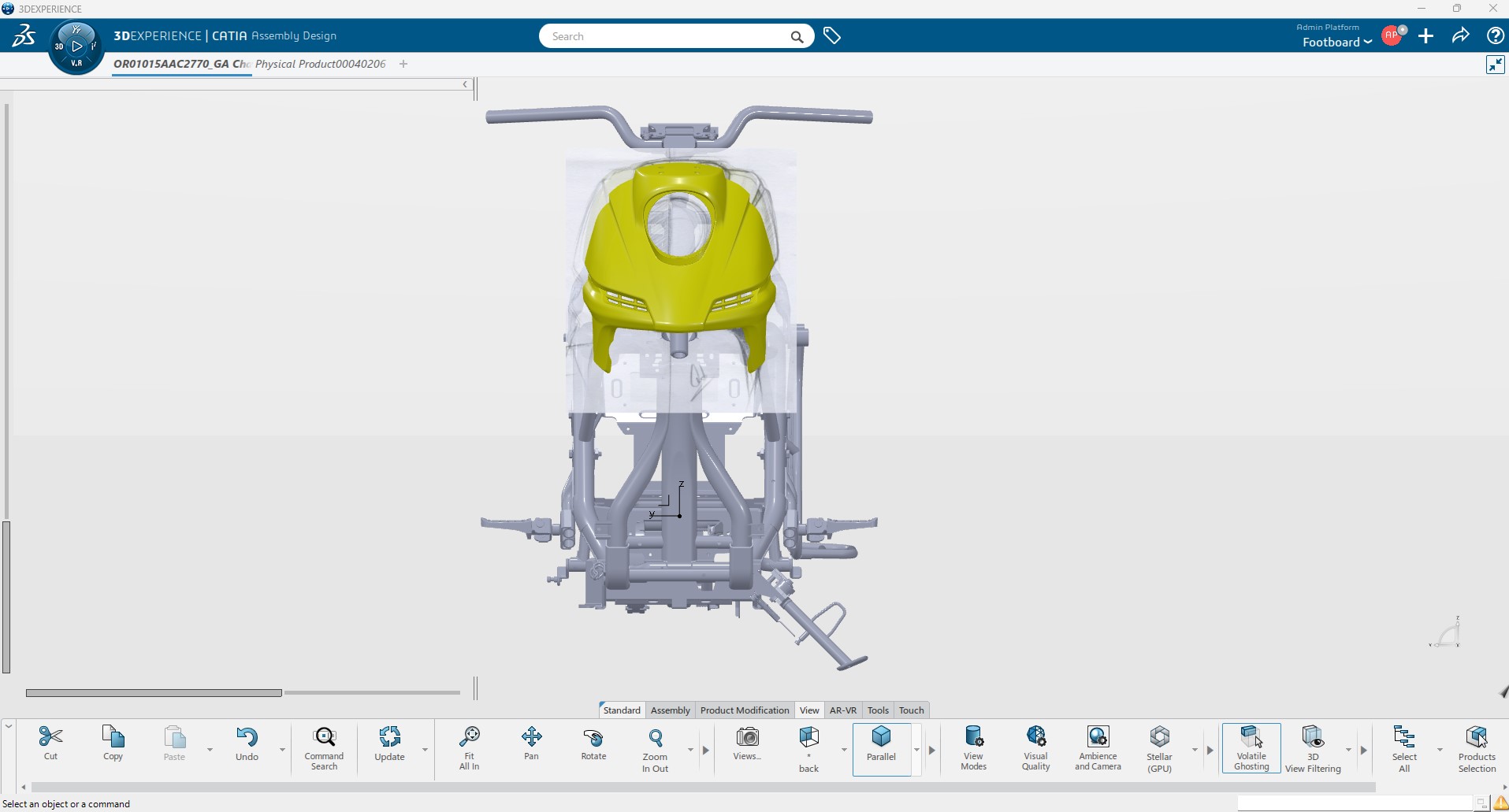

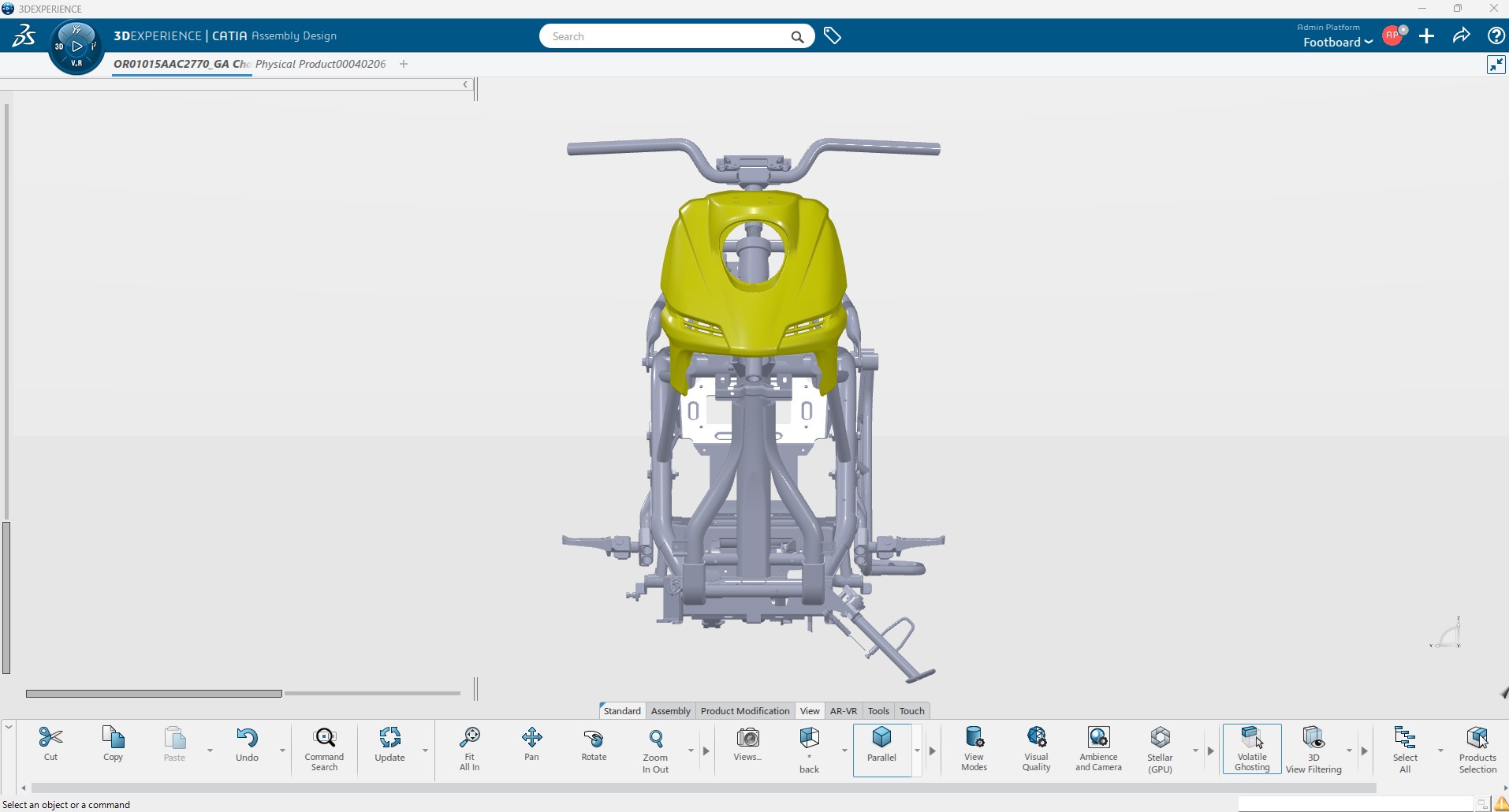

The CAD designer uses a concept sketch of the n-First's front fascia as a reference over the designated area, creating its intricate curves with precision in CATIA on the 3DEXPERIENCE platform.

Bringing Purpose-Driven Design to Life

Conceptualizing, engineering and building a rugged electric vehicle from the ground up is a complex process. That’s why Numeros Motors sought advanced design and engineering software that could help its team rapidly develop every component of its vehicles.

In need of expert guidance, Numeros Motors turned to local Dassault Systèmes business partner EDS Technologies, who recommended CATIA on the 3DEXPERIENCE platform. EDS Technologies demonstrated how the solution could support Numeros Motors’ design ambitions, showcasing how other electric vehicle (EV) clients already benefit from the platform and its capabilities to design faster, smarter and more efficiently.

“With prior experience of CATIA, it was easy for me to see the strengths of the Dassault Systèmes software,” Soundararajan said. “I was convinced it would provide us with the ability to streamline the design process and expedite time to market.”

Numeros Motors took advantage of its new design capabilities immediately. Today, its engineers leverage SOLIDWORKS to quickly create, visualize and validate early product concepts, before moving into CATIA for more detailed and complex design work.

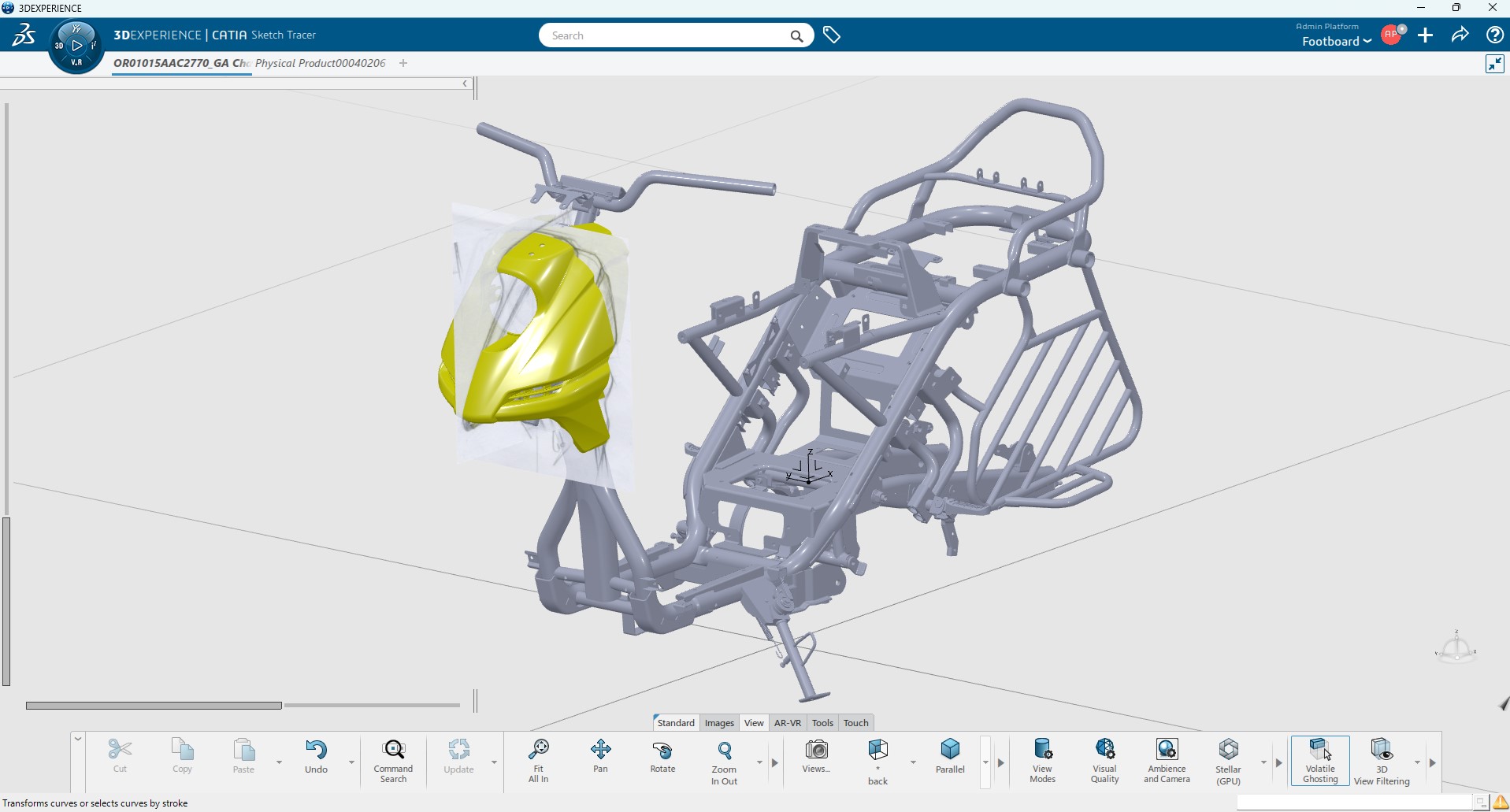

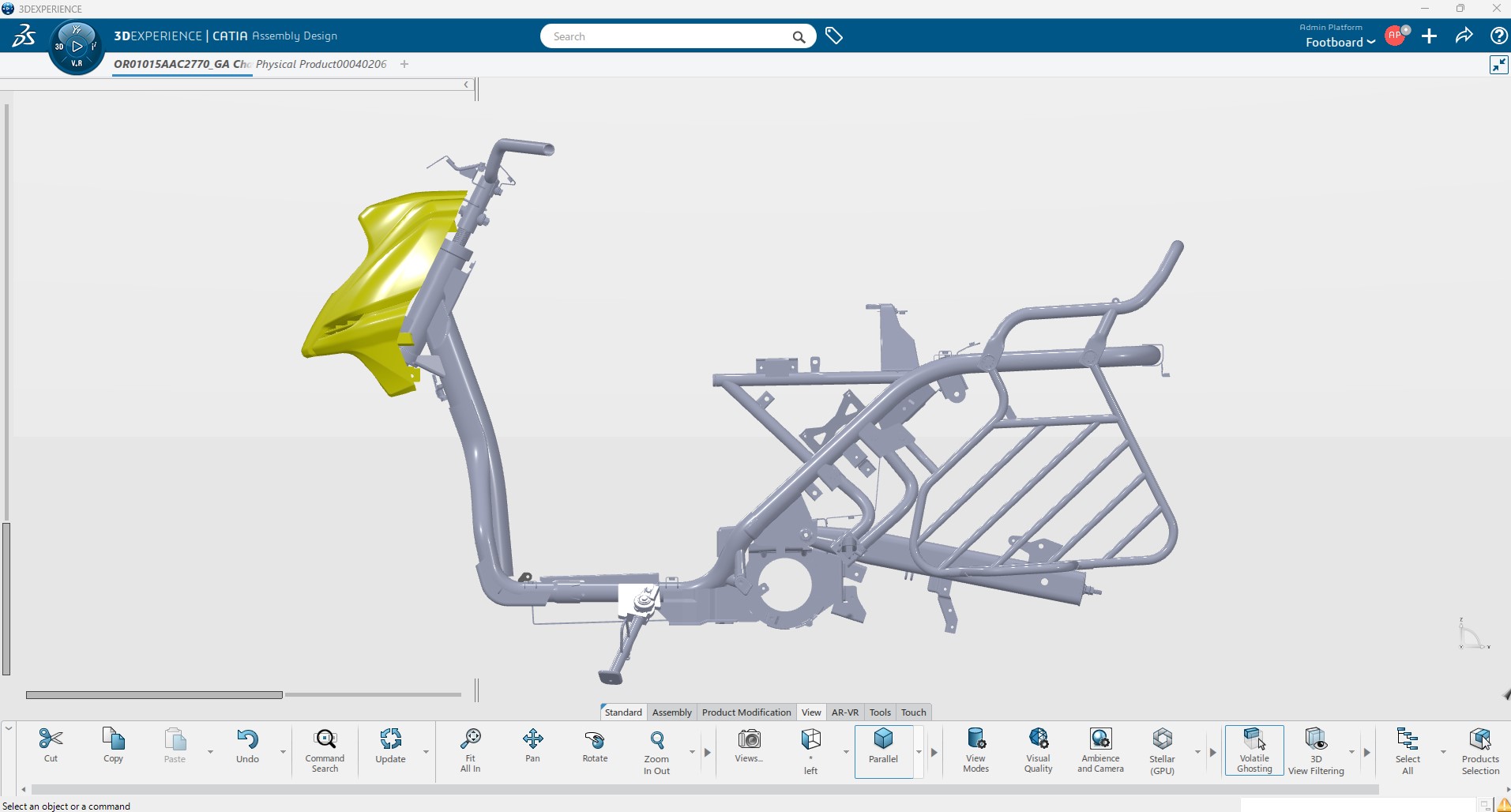

“CATIA has been pivotal in streamlining our design process,” Soundararajan said. “It allows us to transition seamlessly from 2D sketches to detailed 3D models, helping designers and engineers better visualize their work.”

For example, the front fascia of Numeros Motors’ new product, n-First, is intricately curved. Modelling this accurately with other CAD solutions would have been challenging. “Using CATIA, we were able to create these curves with precision,” Soundararajan said. “We can carefully design both the visible and internal surfaces and seamlessly integrate mounting points and snap features, simplifying the design process and improving functionality.”

Soundararajan and his team are particularly impressed with CATIA’s specialized workbenches – customized workspaces with dedicated applications for a wide range of processes such as surface modeling, part design and assembly design. “Each workbench is designed for a specific stage of product development and supports the design of everything from simple components like switches to complex body panels and chassis,” Soundararajan said. “This flexibility enables efficient transitions between phases, reduces errors and improves overall design quality.”

CATIA on the 3DEXPERIENCE platform has enabled us to achieve concept-to-pre-production development in just 14 months, compared to the typical 18 to 20 months required with other solutions.

Expediting Design and Manufacturing Processes

As well as expediting the design stage, Numeros Motors’ use of the 3DEXPERIENCE platform has transformed production processes. That’s because CATIA’s 3D modeling capabilities enable engineers to validate design accuracy before manufacturing begins.

“CATIA on the 3DEXPERIENCE platform has enabled us to achieve concept-to-pre-production development in just 14 months, compared to the typical 18 to 20 months required with other solutions,” Soundararajan said. “This significant reduction is due to more efficient design workflows and enhanced team collaboration. On top of this, CATIA gives us early visibility into key manufacturing features like bends, cuts and mounting points by rapidly converting 2D sketches into 3D CAD models.”

Specialized workbenches also help. “The sheet metal and plastic workbenches allow us to address material-specific needs and manufacturing constraints early,” Soundararajan said. “As a result, we can streamline the design process and make parts more manufacturable and cost-effective. We can do this even with tight deadlines – and without compromising quality.”

Innovating for the Future

Numeros Motors has unveiled the design of n-First at the Bharat Mobility Global Expo 2025 in New Delhi, and has more innovative products in the pipeline, including a sporty, youth-oriented scooter and a three/four-wheeler EV. To develop and validate these complex products as quickly and cost-effectively as possible, Numeros Motors plans to leverage additional solutions on the 3DEXPERIENCE platform like electrical wire harness engineering capabilities. The company is also interested in adopting simulation applications.

“We see great potential in SIMULIA Abaqus,” Soundararajan concluded. “Its advanced capabilities for simulating the performance of parts and assemblies under real-world conditions will help us expedite engineering, reduce our reliance on physical prototypes and drive greater efficiency as our product portfolio grows.”

Focus on Numeros Motors

Numeros Motors has a vision to continually create cutting-edge clean mobility solutions designed to make a positive impact on the environment and in the lives of its customers. Its mission is to put 250,000 EVs on the road by introducing multiple products, variants and services, and by expanding its distribution network to over 250 cities in India and beyond.

For more information: www.numerosmotors.com

Focus on EDS Technologies

EDS Technologies, with over 30 years of experience, delivers technology solutions that drive digital transformation across manufacturing, high tech, defense, infrastructure, natural resource, and retail sectors. Headquartered in Bengaluru, India, it is a partner of Dassault Systèmes and the largest PLM solutions provider in India, with a customer base of more than 2,000 customers. It addresses the needs for virtual twins for design and manufacturing, business dashboarding for real-time decision-making, 3D printing for manufacturing, electronic design automation, and IP solutions for chips and SOC designs.

For more information: https://edstechnologies.com/