Canray Transportation

By connecting the product lifecycle via a single digital thread in the 3DEXPERIENCE platform, Canray Transportation ensures right-first-time production and supports its sustainability goals in the process.

Engineering Sustainable Rail Interiors

When the Turkish government announced plans to build its first national electric high-speed train – capable of carrying 585 passengers at a speed of 225 kilometers per hour – the challenge was not just to achieve speed and efficiency, but to do so as sustainably as possible.

Canray Transportation, part of industrial manufacturing group Yeşilova, rose to the challenge. The company designs and delivers critical interior components including the ceiling modules, wall panels and lighting, plus the heating, ventilation and air conditioning (HVAC) systems – all optimized to be as lightweight and energy-efficient as possible.

Step onto the Riyadh Metro in Saudi Arabia, the RER NG in Paris, the I-LINT in Germany or the underground train networks in Dubai or Hanoi, and you’ll find interior components engineered by the company. While all these projects are unique, one thing remains unchanged: Canray’s drive for sustainability.

“The future of transportation is being shaped by environmentally friendly and innovative solutions,” said Yasemin Yeşilova, Canray’s general manager, during Eurasia Rail 2025, one of the largest specialized rail systems fairs in Turkey. “At Canray, we are working to contribute to that future. By combining our experience in both national projects and international markets with the principles of sustainability, we continue to guide the direction of the industry.”

To deliver effective and sustainable solutions to the world’s leading rail system manufacturers, Canray takes full responsibility for the entire product lifecycle, from the initial design through to validation and then manufacturing. By connecting all of these processes via a single digital thread in Dassault Systèmes’ 3DEXPERIENCE platform, it not only ensures high quality and efficiency, but reduces waste through right-first-time production.

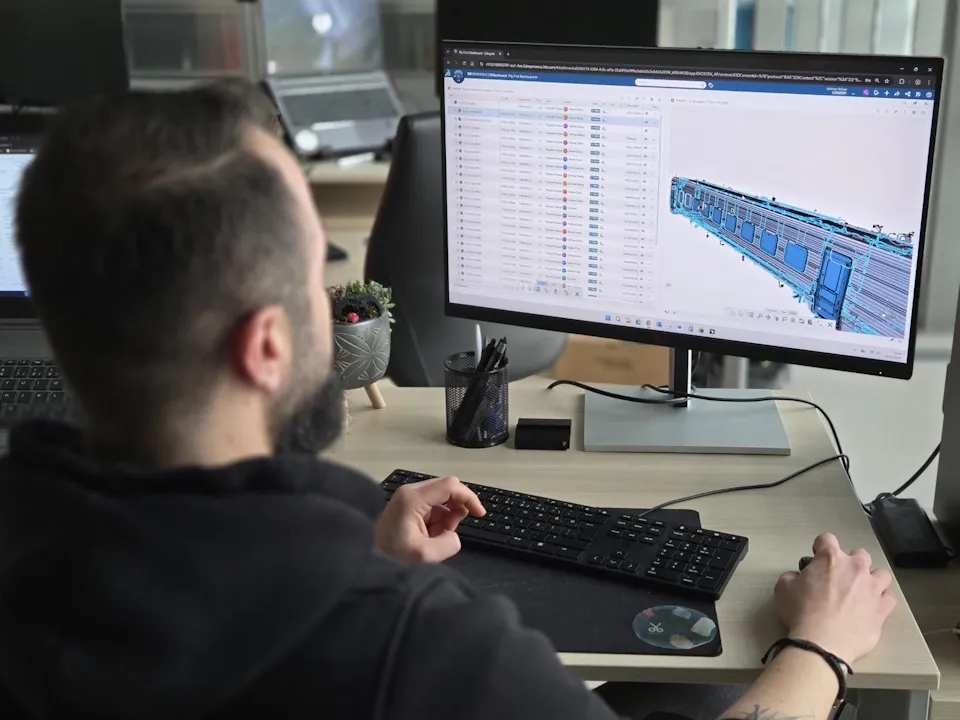

Canray Transportation delivers innovative, lightweight, and sustainable interior solutions for trains worldwide.

Challenge

Before embracing the 3DEXPERIENCE platform, Canray’s engineering teams were using a file-based system to manage design data. Various 3D models of parts – which they had either designed themselves using CATIA V5 or had been sent by sister companies in the Yeşilova Group or key customers – were stored in folders.

Such a disjointed approach could create serious downstream issues like file duplication, broken links and outdated data, leading to multiple reworks, material waste and delays. And these pain points could be amplified when customers revised product data and resent it to Canray. As a consequence, to avoid critical situations, shop floor staff would often chase engineers to manually check they were using the right files, which was time-consuming.

The validation process was also not ideal. Files used to be exported from CATIA V5, converted into a standardized format like STEP, and then imported into a separate tool for structural simulation. If any updates were required, the whole process would need to be repeated.

Canray realized it needed a future-proof environment to tighten the integration among the design, simulation and manufacturing workflows for a more collaborative approach that improves efficiency and also minimizes mistakes.

Solution

Keen to continue using CATIA V5 for design, Canray sought advice from its long-time partner Cadem Digital, who recommended Dassault Systèmes’ 3DEXPERIENCE platform on the cloud.

The 3DEXPERIENCE platform brings together all elements of the product lifecycle in a single environment. Using this new approach, Canray could connect its native data directly to the platform with ENOVIA’s POWER’BY capabilities and use SIMULIA for structural simulation without the need for STEP conversions. Cadem Digital also recommended DELMIA to help engineers plan, simulate and optimize machining processes before any physical manufacturing begins.

The cloud-based version of the platform was another strategic choice. Comparing the cloud with an on-premise installation, Canray found the cloud would be the most cost-effective solution, enabling it to eliminate server maintenance costs while always benefitting from the most up-to-date version of the solution.

Transitioning to the platform was straightforward. Cadem Digital managed Canray’s processes mapping and the platform implementation. The Dassault Systèmes business partner then delivered training, created tailored documentation and provides ongoing support to ensure change would embed into day-to-day operations.

We now have a reliable single source of truth. This enables us to easily collaborate within our teams and with our customers to design sustainable rail solutions that reduce environmental impact while meeting our clients’ exacting standards.

Benefits

Since deploying the 3DEXPERIENCE platform on the cloud, Canray has realized tangible benefits.

The company has not only lowered IT overheads and reduced its maintenance burden, but also enabled collaborative working from anywhere. In addition, sister companies and clients can access specific projects in secure collaborative spaces, enabling multi-company projects to progress without repetitive file exchange or translation work.

Engineers can design complex assemblies such as ceiling modules using CATIA V5 and then instantly connect this design data to the platform. By eliminating separate file storage, broken links are now a thing of the past. With ENOVIA, all teams – from design through to the shop floor – can access the design data and have confidence that what they see is always the latest version. Shop floor stations also display the current design files, so assembly teams no longer need to chase updates from engineers – which in return means they can stay focus on their core work and do not loose valuable time with communication frictions.

This streamlined approach, combined with DELMIA capabilities for manufacturing execution and process planning, minimizes material waste and rework. This right-first-time approach to production directly supports Canray’s sustainability goals by reducing the environmental footprint of its manufacturing processes.

By using the POWER’BY connector, Canray can use its native CATIA V5 files for simulation in SIMULIA, removing time-consuming import/export steps between teams. This has shortened the loop between design and validation from roughly five days to one, while improving confidence in design decisions.

The end result? A far more efficient way of developing innovative and sustainable solutions. For example, for Turkey’s first national electric high-speed train, Canray was able to use CATIA V5 to quickly develop interior structures made from recyclable and lightweight aluminum. It then used its native design data in SIMULIA to optimize and validate weight and heat performance. Through its new-found simulation capabilities, it could also optimize the HVAC and lighting systems during the design stage to minimize energy consumption when in operation. This entire design to validation cycle now takes just one week instead of four.

Canray is now looking to embrace further capabilities offered by the 3DEXPERIENCE platform. It has recently invested in CATIA Composer, which allows to create 2D and 3D technical illustrations, product documentation, interactive product experiences and more – directly from its existing designs. These deliverables are managed and shared directly in the 3DEXPERIENCE platform on the cloud.

Canray also sees potential in leveraging a manufacturing bill of materials to improve production efficiency for rail interior components and ensuring precise material planning to minimize excess inventory and waste. By aligning design data with manufacturing requirements, Canray expects to shorten the design and validation process for complex geometries by 30% to 50%, while enabling more accurate material planning to reduce excess inventory, material waste and energy consumption during production.

Additionally, the company is exploring Failure Modes and Effects Analysis (FMEA) through DELMIA to proactively identify and mitigate risks related to durability, fastening, vibration and wear. This will further enhance product reliability and quality, which extends the lifespan of rail interior components, reducing the need for replacements and supporting a circular economy in rail manufacturing.

Discover more about the Global Modular Architecture industry solution experience.

Focus on Canray Transportation

Established in 2018, Canray Transportation is the youngest member of Yeşilova Group. It supports both domestic and international railway leaders with a wide range of components manufactured with a focus on sustainability – serving light rail systems, metro, and high-speed trains. The product portfolio includes ceiling modules integrated with lighting systems, ventilation ducts, service hatches, complete ceiling assemblies, sidewalls and glass-frame units.

For more information: https://canray.com.tr/en/company/

Focus on Cadem Digital

Operating in digital transformation since 1998, Cadem Digital offers PLM and 3DEXPERIENCE Platform solutions to provide its customers with improved speed and productivity across the full product development lifecycle. It provides innovative, integrated technologies in industrial manufacturing processes primarily for the automotive industry along with aviation, defense and machinery. Cadem Digital is a reliable, experienced and innovative solution partner in the digital transformation journey of brands in the process of creating their future, empowered by its experience and expertise in digitalization, technology, education and innovation in the industry.