Production Insights

Ontologies, AI-driven semantic analysis and ergonomics studies to prevent musculoskeletal disorders will provide unprecedented opportunities.

Insights into the reality of production gained from observation and analysis

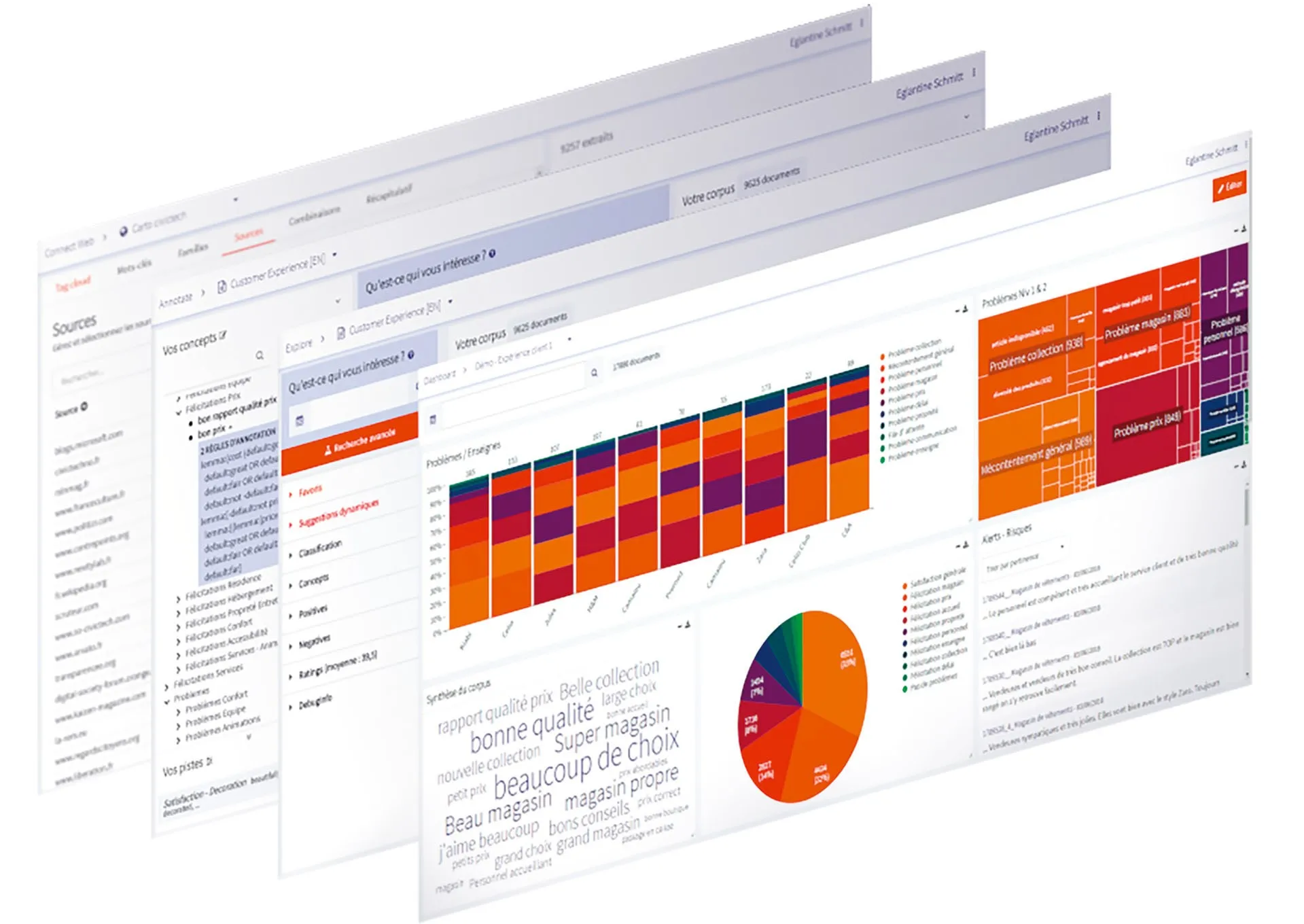

Interpreting and organizing text data with ontologies and AI-driven semantic analysis

In 2020, Dassault Systèmes strengthened its data science capabilities by acquiring French company Proxem, which specializes in advanced (or artificial intelligence (AI)-driven) semantic processing based on natural language processing (NLP) and machine learning. Proxem’s solution and know-how help users turn textual data into ontologies and actionable insights for businesses.

By combining AI-powered semantic modeling and data services applications, users of the 3DEXPERIENCE platform will be able to leverage knowledge buried in requirements, regulations, client and reseller feedback, after-sales service reports, contracts, scientific publications, research reports and clinical trial results, thus enriching their virtual twin experiences. This will provide unprecedented opportunities for collaboration, encouraging innovation and the creation of new products and services, while facilitating planning and execution throughout the extended enterprise.

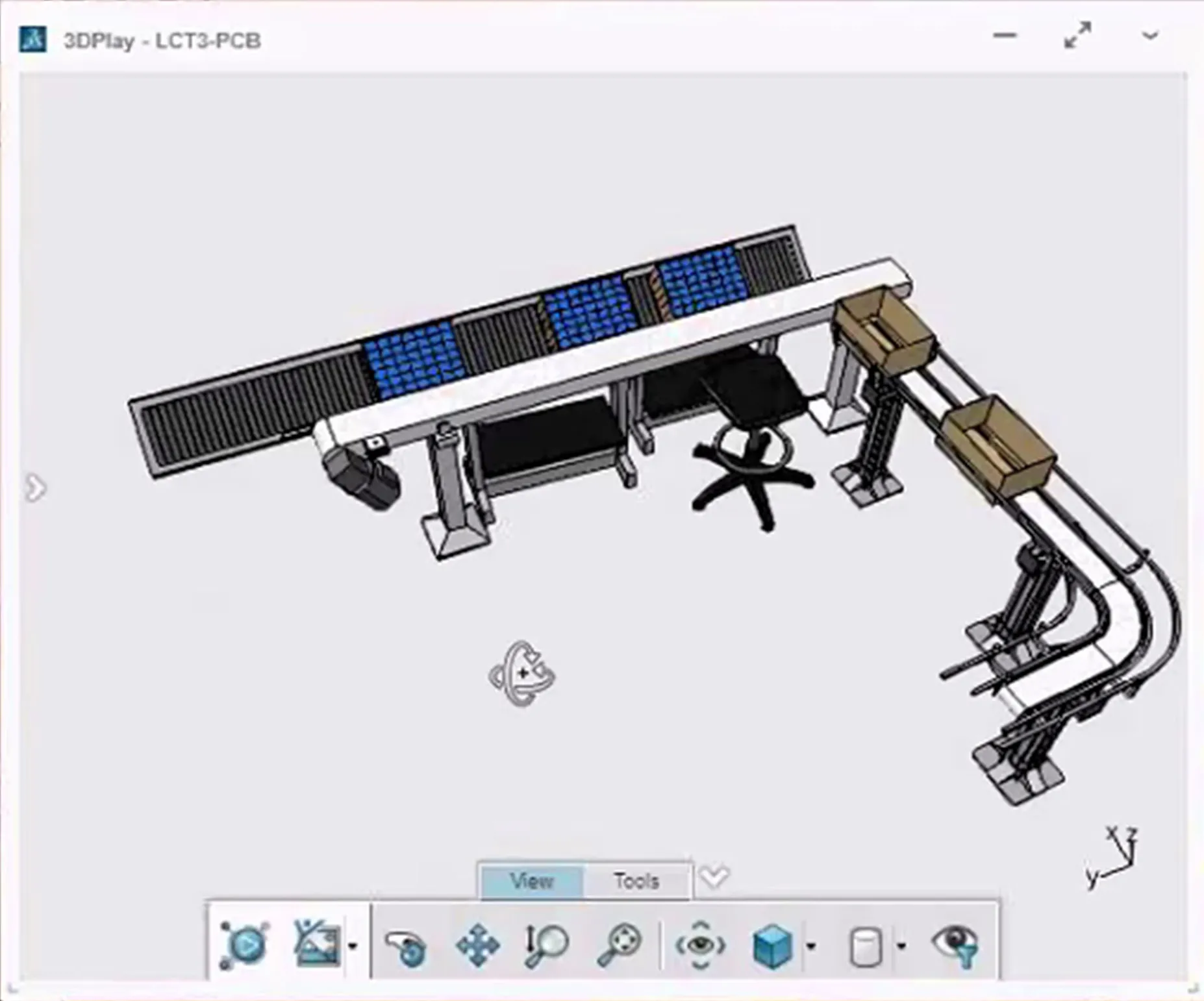

Preventing musculoskeletal disorders in the L'Occitane factory

MyHealth@Work is a Dassault Systèmes service based on the DELMIA solution, developed with L’Occitane en Provence as the pilot client. L’Occitane wanted to prevent the occurrence of musculoskeletal disorders among staff members working on the factory floor. The solution works by capturing the real situations and operational procedures of each workstation, performing an analysis using the workstation’s virtual twin, and shows its risk level.

This assessment – which method engineers would not have had the time or resources to perform – was carried out very quickly in L’Occitane’s factory, analyzing tasks performed in the production and packaging workshop. Method engineers now have access to a MyHealth@Work dashboard based on the Ergonomic Workplace Design solution, which combines two algorithms: Smart Posturing Engine, which automatically positions a virtual manikin, and Ergo4All, which ergonomically assesses the manikin’s posture to determine the risk of joint or musculoskeletal problems.

Using an objective, mathematical model makes all participants in the occupational health ecosystem more accountable. It changes the work done by method engineers, who are now able to spend more time on prevention: together, the virtual twin of the workstation and the associated virtual manikin represent a powerful educational tool to raise operators’ awareness and give them information regarding their own health.