Heavy Mobile Equipment Safety

Embrace a new standard of product development for heavy mobile equipment that emphasizes operator safety and equipment reliability.

Transforming Heavy Mobile Equipment Safety With Innovation

Heavy mobile equipment is central to industries such as mining, construction and agriculture machinery, yet it operates in some of the most extreme and unpredictable environments. As machines grow in complexity, so do the risks associated with their use. From cabin ergonomics to mechanical reliability, every design decision can directly impact safety, productivity, and compliance.

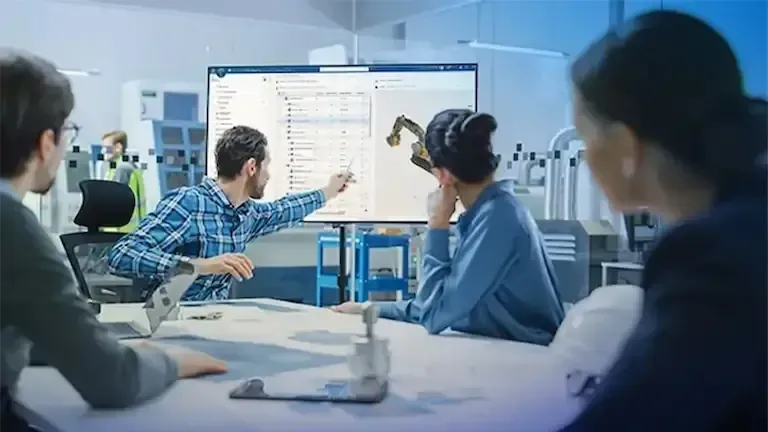

At Dassault Systèmes, we believe that heavy mobile equipment safety must be embedded by design, not added as an afterthought. Through the 3DEXPERIENCE® platform and the 3DUNIVERSES architecture, heavy mobile equipment manufacturers can shift from reactive safety measures to a proactive, simulation-driven approach. Virtual twin experiences bring together simulation, data and design in a unified environment, empowering cross-disciplinary teams to deliver safer and smarter equipment faster.

The analysis process was time-consuming, with many iterations. By leveraging unified modeling and simulation (MODSIM) to run analysis in a platform environment, the simultaneous collaboration between the mechanical design and analysis teams was more efficient. Being able to use both 3D design and structural analysis data has reduced overall development time by more than 30%.

Key Challenges in Heavy Mobile Equipment Safety

- Operator Safety

- Equipment Reliability

- Regulatory Compliance

- Training and Human Factors

Operator Safety

Operator safety is deeply linked to design complexity, ergonomics and the evolving expectations of modern operators. Workers spend long hours in high-stress environments that can quickly become dangerous if machinery is poorly designed. Fatigue, discomfort and limited visibility increase the risk of human error and accidents. According to the U.S. National Safety Council, worker fatigue costs employers between US$1,200 and US$3,100 per employee annually.

To mitigate these risks, Dassault Systèmes enables manufacturers to adopt a human-centric design philosophy, where safety and comfort are core design requirements:

- Human factors engineering (HFE) tools simulate the interaction between operator and machine, optimizing cabin layout, visibility, ingress/egress and control placement.

- Thermal comfort simulations ensure effective HVAC performance under extreme weather conditions. By visualizing airflow and temperature gradients, designers can fine-tune vent placement and airflow paths to prevent discomfort or distraction.

- Real-time data and Industrial Internet of Things (IIoT) integration support fatigue monitoring, operator behavior analysis, and predictive alerts for safety-critical issues.

With electrification on the rise, new safety concerns emerge such as battery thermal management, high-voltage system design, and electromagnetic safety. Dassault Systèmes helps original equipment manufacturers (OEMs) simulate and validate these new systems with the same rigor applied to traditional engine designs.

Equipment Reliability

Idle time is money wasted when it comes to heavy mobile equipment. Maintenance and repair costs reached approximately US$182.5 billion in 2024. Unexpected and unplanned equipment failures will lead to costly downtime, a scenario that manufacturers are keen to avoid. For OEMs, after-sales services account for more than half of their revenue, making consistent equipment availability and reliable support crucial for profit and business growth.

Dassault Systèmes helps manufacturers reduce the risk of failure and increase machine uptime with:

- Virtual twin experiences that create real-time, data-driven digital replicas of equipment

- Advanced simulation tools to test and optimize components under realistic stress, vibration and wear scenarios

- Predictive maintenance strategies powered by IIoT data, helping anticipate failures before they occur

Additionally, real-world usage data can now feed back into the design process, enabling engineers to continuously improve future iterations based on actual operator behavior and equipment stress profiles in the field. This closed-loop development model transforms reliability from a reactive service task to a strategic design driver.

Regulatory Compliance

Regulatory compliance is a significant challenge for manufacturers, given the demanding environments in which these machines operate. Heavy mobile equipment must be robust, efficient and comply with national regulations, especially during the design and manufacturing phases. Complex international regulations also add pressure on manufacturers to design and produce reliable equipment that adheres to various standards.

With the 3DEXPERIENCE platform, manufacturers can:

- Trace requirements and decisions throughout product development

- Simulate and validate designs against global safety, emissions and ROPS/FOPS standards

- Maintain a single source of truth across mechanical, electrical and systems engineering disciplines

Cybersecurity has become a safety concern, especially in autonomous and connected machines. The 3DEXPERIENCE platform enables manufacturers to adopt model-based systems engineering (MBSE) which helps teams design safer, more secure systems that meet stringent functional safety and cyber-resilience standards.

Training and Human Factors

The heavy mobile equipment industry is facing a critical talent shortage. As experienced operators retire, onboarding new talent becomes more challenging due to the complexity of modern machinery and the lack of hands-on experience.

Dassault Systèmes addresses this issue with immersive, simulation-driven training experiences:

- Virtual twin models serve as the basis for realistic operator training, replicating mechanical, thermal, hydraulic and electronic behavior

- Immersive simulations in 3DUNIVERSES provide a safe environment for operators to practice operations, understand safety protocols, and respond to emergencies

- Training modules can be customized for role, equipment type and environment, enabling scalable workforce development across multiple sites

By transforming training into an interactive, experience-based process, OEMs and operators can bridge the knowledge gap while enhancing safety and confidence on the job.

Future-Proofing Safety in Heavy Mobile Equipment

As industrial machinery becomes more autonomous, electrified and connected, the safety landscape is evolving fast. Dassault Systèmes is helping OEMs stay ahead of the curve with a suite of forward-looking capabilities:

- Electrification-ready simulation to ensure thermal safety, battery integration and shock protection

- Secure design frameworks for connected and semi-autonomous systems, embedded with cybersecurity and MBSE principles

- Sustainable engineering tools that allow manufacturers to balance eco-friendly materials and emissions goals without compromising durability or operator safety

- Real-time feedback loops connecting the field with engineering to continuously optimize performance and safety

- 3DUNIVERSES that deliver shared experiences for all stakeholders — from designers to operators to service teams — bridging the digital and physical worlds

With the rising focus on environmental, social and governance (ESG) policies, Ferrit has put a five-year plan in action that will reduce our reliance on companies that emit greenhouse gases. Thermal coal customers accounted for 50% of revenues in 2019, [but] down to… 23% in 2021, and we are targeting this sector to be much lower within five years. We are also increasing our investment in designing equipment like electrical vehicles that help client sites to reduce their carbon footprint and improve worker safety.

Transforming Heavy Mobile Machinery and Equipment Manufacturing

Key Benefits of Heavy Mobile Equipment Safety With The 3DEXPERIENCE Platform

Design for Safety, Test Without Risk

With high-fidelity virtual twins, manufacturers can simulate their equipment in real-world and extreme conditions. This identifies risks and optimizes designs before a single part is built.

Increase Reliability and Reduce Downtime

Virtually validate performance across structural, thermal, fluidic and acoustic domains. This enables teams to detect design flaws early, eliminate costly rework and boost product reliability.

Achieve Compliance with Full Confidence

Track and document every safety requirement, design decision and test outcome throughout the development lifecycle. The platform ensures regulatory compliance through end-to-end traceability.

Empower Cross-Functional Collaboration

Break down silos between engineering, simulation, manufacturing and service. With a single digital thread, everyone works from a shared source of truth.

Train with Immersive Experiences

Use virtual twins to create realistic, scenario-based learning environments. It’s perfect for onboarding new operators and preparing for emergency procedures without physical risk.

Integrate Sustainability and Safe Design

Explore eco-friendly materials, lightweight structures and energy-efficient systems without compromising on operator safety or structural integrity. This supports both regulatory and ESG goals.

Autonomous and Connected Machine Safety

Design and validate cyber-physical systems for connected or semi-autonomous machines using MBSE, ensuring that cybersecurity and functional safety are built in from the start.

Anticipate Future Failures

With real-time feedback loops powered by IIOT data, machines can anticipate failures and prevent machine downtime. This transforms reliability from a reactive task to a strategic design driver.