IoT Remote Monitoring

Real-time insights empower manufacturers to safeguard assets, optimize operations and reduce costly downtime, turning data into a strategic advantage.

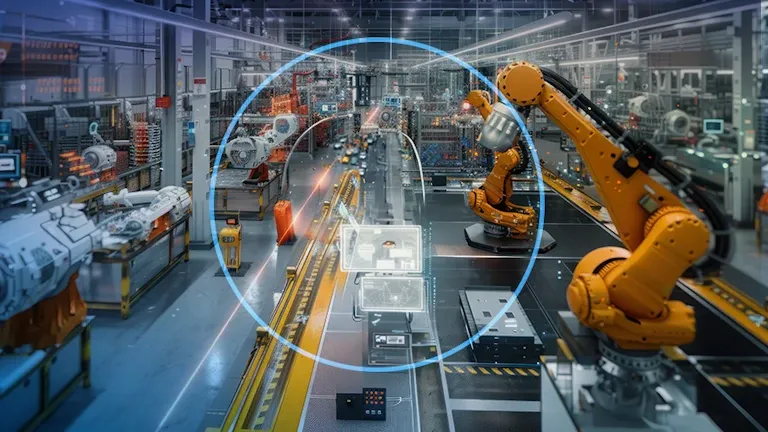

How IoT Is Transforming Industrial Equipment

The Internet of Things (IoT) is reshaping the industrial landscape by connecting machines and factories through smart sensors that continuously capture operational data such as temperature, pressure, energy consumption and production metrics. On the 3DEXPERIENCE® platform, this data is securely centralized, providing original equipment manufacturers (OEMs) and factory operators with end-to-end visibility into:

- Real-time equipment performance

- Early detection of asset degradation

- Predictive insights to prevent failures and disruptions

IoT remote monitoring addresses the challenge of limited real-world visibility, enabling OEMs to make more informed decisions that drive higher uptime, lower maintenance costs and stronger customer satisfaction.

Turning Sensor Data Into Actionable Intelligence

Connecting IoT remote monitoring systems to a unified digital platform enables full traceability across the engineering, manufacturing and after-sales stages.

- Manage and Maintain Equipment With Data

- Optimize Asset Performance With Connectivity

- Support Outcome-Based Models With Insights

Manage and Maintain Equipment With Data

IoT technology powers advanced analytics to detect abnormal patterns, trigger alerts and predict maintenance needs. Each potential issue is linked to the service bill of materials (SBOM) on the 3DEXPERIENCE platform, enabling teams to automate digital work instructions and select the right tools and spare parts for first-time-right repairs. This eliminates guesswork and supports measurable cost savings.

Optimize Asset Performance With Connectivity

Data from IoT-enabled equipment is captured on the cloud-based 3DEXPERIENCE platform, giving manufacturers real-time visibility into asset and system health. Teams can diagnose performance issues remotely, validate conditions using virtual twins and apply corrective action without the need for on-site visits.

Support Outcome-Based Models With Insights

Valuable insights into uptime, usage cycles and environmental conditions enable manufacturers to accurately price pay-per-use models and confidently scale Equipment as a Service (EaaS) contracts. This transparency addresses a major industry challenge by enabling predictable, performance-driven service agreements supported by real-world operational data.

Data-Driven After-Sales Services

Discover how virtual twins and advanced analytics drive performance optimization, operational efficiency and superior customer satisfaction.

Enhancing IoT Value With Virtual Twins

When paired with virtual twin technology, IoT data becomes a powerful driver of profitability for industrial equipment manufacturers.

The Installed Base Virtual Twin (IBVT) integrates real-time field data with lifecycle information to create a living digital replica of each asset in operation. This helps OEMs make informed decisions that protect uptime and maximize revenue.

IoT Remote Monitoring Podcast

Learn how OEMs leverage the IBVT to predict failures, test what-if scenarios and plan proactive after-sales services.

Build a Connected EaaS Ecosystem

What You Gain With Predictive Maintenance Tools on the 3DEXPERIENCE Platform

End-to-end visibility

A connected dashboard contextualizes IoT sensor data within engineering, manufacturing and service definitions, creating a single source of truth for all teams.

Faster decision-making

Real-time operational data is automatically shared across multidisciplinary teams, enabling informed decisions that eliminate delays, guesswork and the risk of misalignment.

Higher service value

OEMs can unlock new revenue streams, such as targeted retrofits, optimized spare parts offerings and streamlined production processes, by analyzing equipment and factory behavior.

Customer and operational satisfaction

Virtual twin integration allows OEMs to deliver evidence-based service recommendations, accurate performance forecasts and transparent uptime reporting to build stronger customer trust and operational efficiency.

Learn How Dassault Systèmes Connects Industrial Equipment

Optimize manufacturing with predictive maintenance

Leverage virtual twins to simulate performance, anticipate maintenance needs and prevent costly downtime.

Maximize uptime with maintenance management

Use cloud-based platforms to align service schedules with production, minimize disruptions and reduce operational costs.