Harnessing the Power of Model-Based Definition

In the ever-evolving landscape of product design and manufacturing, efficiency, accuracy, and communication are paramount. Traditional methods of conveying product information through 2D drawings have long been the norm, but they come with limitations in today's fast-paced industry.

However, Model-Based Definition (MBD) offers a paradigm shift by embedding manufacturing data directly into 3D models. This approach not only streamlines communication but also enhances accuracy and facilitates automation in manufacturing processes.

The Evolution from 2D Drawings to Model-Based Definition

For decades, 2D drawings have served as the primary means of conveying design and manufacturing information. However, this method has its drawbacks. 2D drawings can be prone to misinterpretation, leading to errors in manufacturing and assembly. Moreover, maintaining consistency between design documents and actual production can be challenging, especially as designs become more complex.

Model-Based Definition addresses these challenges by integrating manufacturing data directly into 3D models. Rather than relying solely on annotations and dimensions in 2D drawings, engineers can now define geometric and tolerancing information directly within the digital model, creating a single source of truth for all stakeholders involved in the manufacturing process.

The Evolution from 2D Drawings to Model-Based Definition

For decades, 2D drawings have served as the primary means of conveying design and manufacturing information. However, this method has its drawbacks. 2D drawings can be prone to misinterpretation, leading to errors in manufacturing and assembly. Moreover, maintaining consistency between design documents and actual production can be challenging, especially as designs become more complex.

Model-Based Definition addresses these challenges by integrating manufacturing data directly into 3D models. Rather than relying solely on annotations and dimensions in 2D drawings, engineers can now define geometric and tolerancing information directly within the digital model, creating a single source of truth for all stakeholders involved in the manufacturing process.

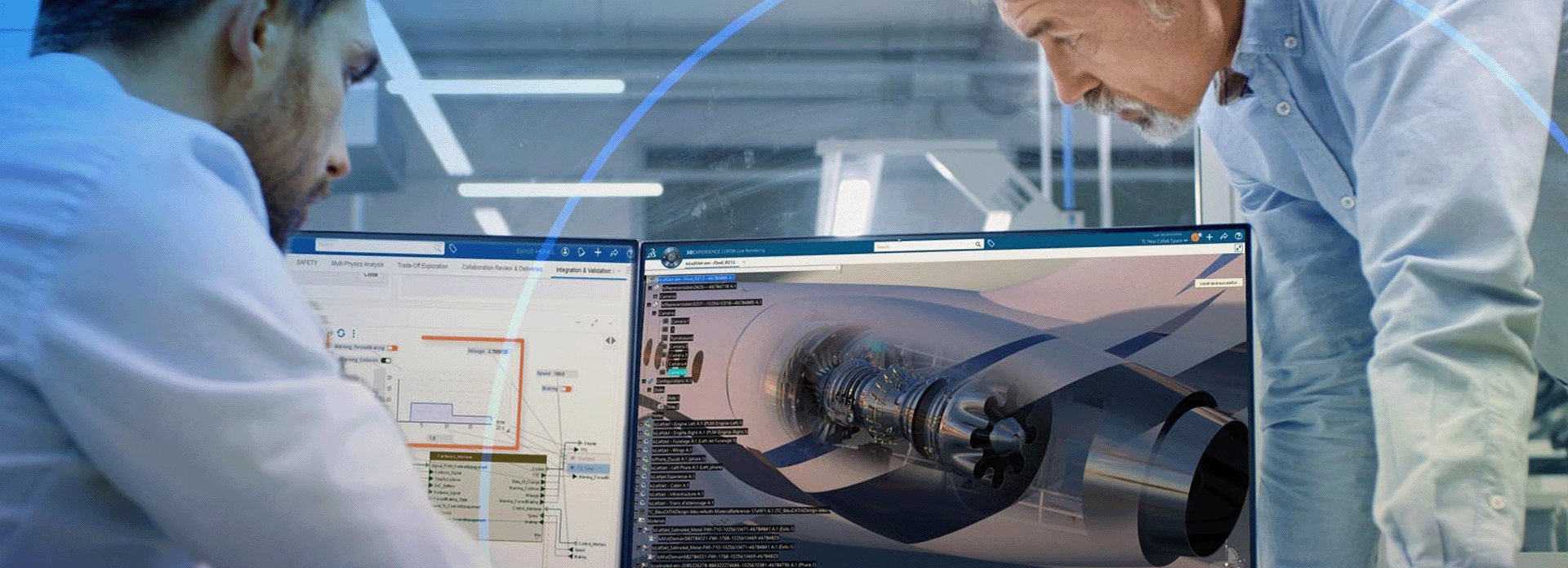

Seamless Collaboration with the 3DEXPERIENCE Platform

The integration of browser-based CAD tools with platforms like the 3DEXPERIENCE offers numerous benefits for collaboration in the CAD workflow.

SOLIDWORKS xDesign

Get ready for the next generation of design solution, developed by the same team that brought you SOLIDWORKS 3D CAD

Streamlining Communication and Improving Accuracy

By embedding manufacturing data into 3D models, MBD streamlines communication between design and manufacturing teams. Engineers can convey design intent more clearly, reducing the likelihood of misinterpretation and errors during production. Additionally, MBD promotes better collaboration among stakeholders, as everyone works from the same digital model, ensuring consistency throughout the product lifecycle.

Moreover, MBD improves accuracy by eliminating the discrepancies that can arise between 2D drawings and 3D models. With all relevant information contained within the digital model, there is less room for interpretation, leading to more precise manufacturing processes and higher-quality end products.

Facilitating Automation in Manufacturing Processes

One of the key advantages of MBD is its ability to facilitate automation in manufacturing processes. By embedding manufacturing information directly into the digital model, engineers can automate various aspects of production, such as generating toolpaths for machining operations or programming robotic assembly systems.

Tools like Manufacturing Definition Creator enable engineers to define dimensions, tolerances, and annotations directly on 3D models, further enhancing the capabilities of MBD. These tools provide a user-friendly interface for creating and managing manufacturing data, ensuring clarity and consistency throughout the manufacturing process.

Conclusion

Model-Based Definition represents a significant advancement in the way product information is conveyed and utilized in manufacturing. By embedding manufacturing data directly into 3D models, MBD streamlines communication, improves accuracy, and facilitates automation in manufacturing processes. Tools like Manufacturing Definition Creator empower engineers to leverage the full potential of MBD, ensuring clarity and consistency throughout the product lifecycle. As industries continue to embrace digital transformation, MBD will play an increasingly vital role in driving efficiency and innovation in manufacturing.