Zimplistic

The Singapore-based company adopted the 3DEXPERIENCE® platform on Cloud for its collaborative workspace that allows distributed and hybrid work teams to work together seamlessly on upgrading its core product, a kitchen robot dubbed the Rotimatic.

An innovative kitchen robot

Rotis, the Indian version of flatbreads, are a staple food in India, made daily in almost every household. “In fact, a billion people make over four billion rotis each and every day by hand,” says Pranoti Nagarkar, co-founder and CEO of automated kitchen appliance company Zimplistic. “They are integral to our diet as they are healthy, but making them is a daily chore.”

Nagarkar’s career as a mechanical and product design engineer exposed her to the potential of automation robotics, as well as the importance of user experience design. As a result, she, along with her co-founder Rishi Israni, a software engineer, came up with an idea for a consumer product that could help many Indian households: an automatic roti-making machine.

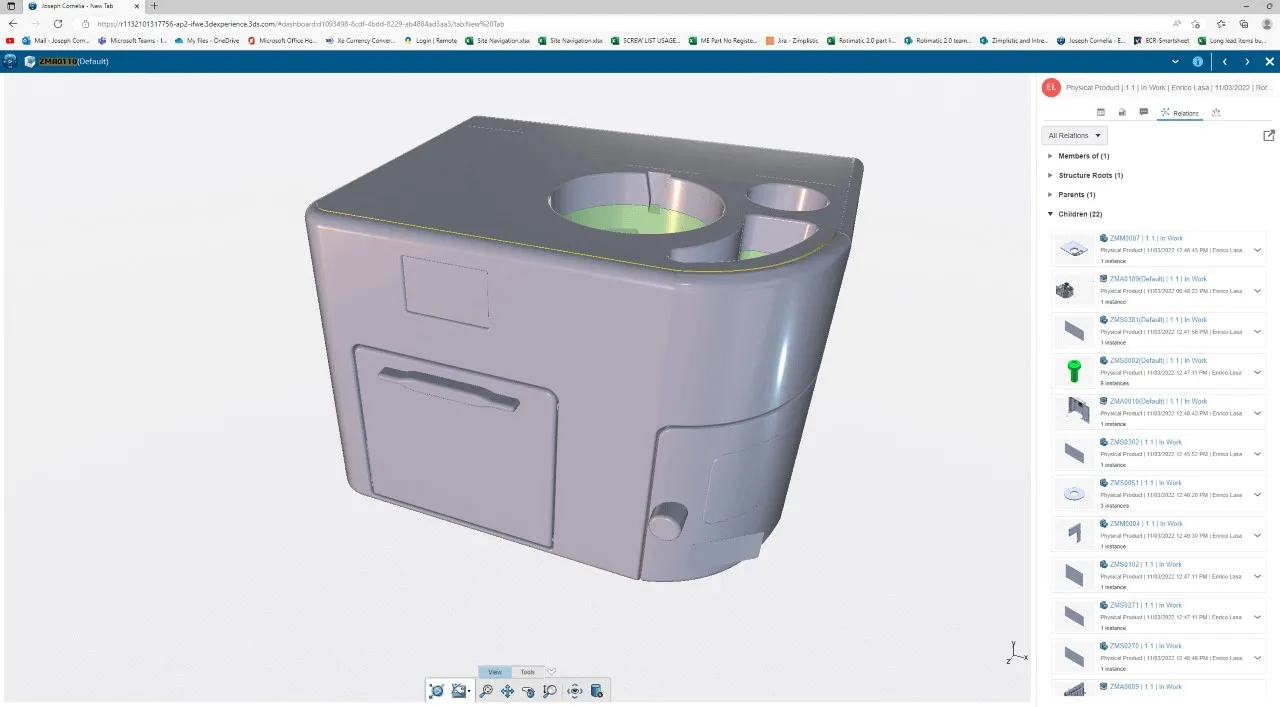

Well-versed in CAD software, Nagarkar chose SolidWorks to create the world’s first roti-making robot from scratch – the Rotimatic. It houses 300 different parts, including 10 motors, with artificial intelligence (AI) and internet of things (IoT) technology developed by the inventor and engineer duo.

The Rotimatic has reached 100,000 homes and facilitated the making of 165 million rotis around the world since its market launch in 2017 – all thanks to its one-of-a-kind design.

Having the right tools to develop the complex kitchen robot is crucial. The Rotimatic takes data from 15 different sensors to automatically adjust the proportion of flour and water so that it can mix, knead, flatten and cook perfect flatbreads in just 90 seconds. The kitchen robot also ensures the optimum consistency, temperature and positioning necessary to produce evenly toasted rotis with “the magical poof and fluff” that are the hallmarks of roti perfection.

Challenge

Zimplistic consistently introduces upgrades to the Rotimatic with innovative features based on user feedback. However, the company found that its existing system was holding it back: Engineers working in disparate locations such as the Philippines and Singapore were struggling to collaborate on designs and found it difficult to share information with their manufacturing facility in Malaysia. Data were often stored in siloed repositories, which meant information was fragmented and sometimes lost.

Meanwhile, a manual review and release process was error-prone. There was no version control and change management was ineffective, making it very difficult to get an accurate bill of materials.

As a result, Zimplistic sought a collaborative design platform that could help it optimize its processes and heighten its efficiency.

Solution

Being already a Dassault Systèmes customer, Zimplistic chose to maintain its existing SOLIDWORKS infrastructure and to adopt the 3DEXPERIENCE platform on Cloud including ENOVIA, which enables the team to collaborate across borders with shared dashboards for engineering bill of materials (BOM), product structure and project management. Meanwhile, the company’s legacy SOLIDWORKS data is connected to the platform via POWER’BY, serving as a vital link to existing design files.

Instead of using multiple disparate software programs for 3D design and product management, the 3DEXPERIENCE platform on Cloud enables us to work much more efficiently across different teams and locations and to advance our new ideas much faster.

Benefits

Today, Zimplistic’s engineers are using the 3DEXPERIENCE platform on Cloud to create an upgraded version of their kitchen robot. Engineers working on any one of the Rotimatic’s 300 parts can now collaborate at any time, from anywhere, safe in the knowledge that they are working on the latest iteration of the design thanks to the 3DEXPERIENCE platform’s version control and change management features.

But it’s not just engineers who are benefiting from the implementation. No longer having to open design files natively in SOLIDWORKS, Zimplistic’s non-technical employees can now view design changes and even make annotations using their mobile devices through the 3DPlay widget which leverages the cloud.

Employees right across the business also benefit from the platform’s product data management capabilities, which enable files and documents to be accessed from a single location, maximizing productivity and improving product quality.

Focus on Zimplistic

Zimplistic's core product is the Rotimatic, an AI & IoT powered kitchen robot that makes flatbreads.

For more information: https://rotimatic.com/