Sofia Med

Implementing DELMIA Quintiq advanced planning and scheduling solutions has led to transformative results across Sofia Med’s supply chain.

DELMIA Quintiq Company Planner has drastically improved our visibility of the entire supply chain very soon after the completion of the project.

Extracting the Most Value from Copper

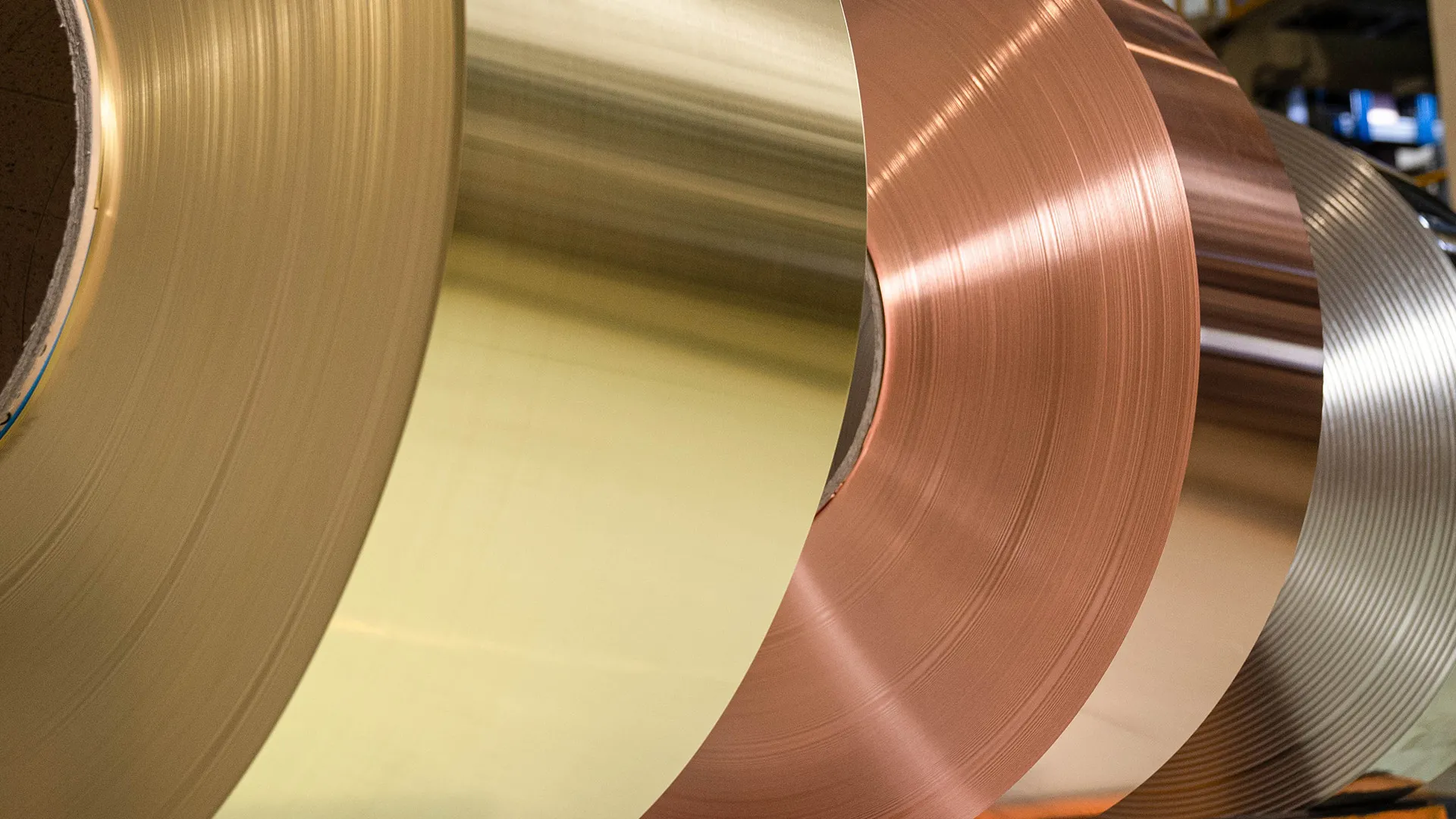

From its foundry, rolling and extrusion mills in Sofia, Bulgaria, Sofia Med has the capacity to produce 140,000 metric tons of copper and copper alloy products per year. Used in everything from renewable energy systems and electric vehicles to buildings, the manufacturer’s range of copper sheets, strips, rods and plated bus bars are a cornerstone of modern technology, sought after for their excellent electric and thermal conductivity, durability and resistance to corrosion.

Sofia Med’s customers value its ability to deliver customized copper products and apply advanced plating and coating techniques to enhance product durability and performance, particularly for electrical applications. The company’s fully integrated production process, encompassing copper melting and casting, hot and cold rolling, extrusion, and precise cutting and slitting, means it can deliver a tailored copper product for virtually any application in any industry, including the energy, automotive and construction sectors.

Challenge

Based in Bulgaria, Sofia Med produces a wide range of rolled and extruded copper and copper alloy products. Because of the nature of its products, the company’s production process is complex, involving anywhere from 7 to 20 process steps and up to 50 separate resources. To stay on top of costs, lead times and avoid bottlenecks, Sofia Med sought a planning and scheduling solution that would bring full visibility to its production processes, improve material flow and support effective resource planning.

Solution

Sofia Med selected the industry-leading production planning and scheduling solution from Dassault Systèmes and WHISCO Consultants, as prime contractor for the highly challenging implementation projects. It uses DELMIA Quintiq to develop detailed production plans that prioritize customer orders, integrate material and capacity requirements and constraints and optimize its resources.

Benefits

Dassault Systèmes’ planning and scheduling solution gives Sofia Med full visibility of its production value chain via a user-friendly interface. This allows it to plan ahead, respond rapidly to unplanned production events and stay on top of customer orders. Delivery performance has increased by 50%, leading to reduced lead times and a better-managed, more evenly distributed inventory.

Strategic Planning Improves Material Flow

Sofia Med’s use of DELMIA Quintiq, Dassault Systèmes’ advanced planning and scheduling solution, plays a critical role in optimizing its complex production workflows, improving delivery performance and reducing lead times, all while keeping inventory costs under control.

The company’s decision to implement the solution stemmed from a need to master complexity. Every copper product is 100% made to order, uses up to 50 separate resources, and involves up to 20 production steps, taking anywhere from 5 to 45 days to make. The escalating cost of copper also demands a strong focus on inventory. Sofia Med needed a way to gain better visibility of its production processes, streamline material flow, and improve scheduling accuracy.

Working with its technology partner WHISCO Consultants, Sofia Med began by implementing DELMIA Quintiq’s Company Planner solution. Within months, WHISCO helped the company map its needs and adapt its workflows to fit the solution’s framework. Critically, Sofia Med gained the capabilities to optimally plan orders in terms of priority and get early alerts for planning errors, particularly for complex work orders.

Once the manufacturer was fully up and running on DELMIA Quintiq Company Planner, it made steady improvements to its production processes and delivery performance. This was largely attributed to enhanced material flow between the foundry and the downstream rolling factory.

Mapping Processes to Optimize Schedules

Following the success of the first phase of its digital transformation, Sofia Med went on to implement DELMIA Quintiq’s Scheduler solution. Again, working with WHISCO Consultants, the company mapped its existing processes to the solution’s capabilities to achieve accurate and efficient scheduling, supporting it in making the best use of its resources and effectively planning staff shifts.

Work orders and production schedules are now aligned with a medium-term production plan.

“Company Planner has drastically improved our visibility of the entire supply chain very soon after the completion of the project” said Sofia Med's head of Supply Chain.

Achieving High Performance and Efficiency

Implementing Dassault Systèmes’ advanced planning and scheduling solutions has led to transformative results across Sofia Med’s supply chain. Increased visibility and a structured, rule-based approach to planning and scheduling have seen delivery performance surge by 50%, while lead times have reduced by up to 15%, depending on the product.

Inventory management is now more streamlined, ensuring materials are available at the right time, and the accuracy of the monthly production plan is now close to 100%. Additionally, with the ability to run what-if scenarios, Sofia Med can optimize the production schedule and adapt quickly to disruptions or unexpected issues.

“DELMIA Quintiq provides Sofia Med with invaluable visibility of our supply chain and unwavering reliability towards our customers, further propelling our company’s development,” said Petros Kyrou, supply chain management senior manager at Sofia Med.

The Projects and Recognition

The two projects were implemented [basically] on-time and on budget. “Critical success factors were the Express QPLC (Quintiq Project Lifecycle) Methodology that was used and the very good co-operation between the Sofia Med and WHISCO teams” according to Periklis Tsahageas, WHISCO Consultancy Manager. The projects received two awards in the 2023 Manufacturing Excellence Awards, one in the 2024 BITE (Business IT Excellence) Awards and were presented at the December 2023 Lean Manufacturing Conference, in Athens.

Focus on Sofia Med

Sofia Med produces a wide range of rolled and extruded copper and copper alloy products such as sheets, strips, plates, circles, disks, bare and plated copper bus bars, rods, profiles, components, and wire, which are used in a wide variety of industrial - electrical – automotive and building applications. The company is part of the Copper Segment of ElvalHalcor Hellenic Copper and Aluminium Industry S.A., Sofia Med is based in Sofia, Bulgaria, and has three production units: foundry, rolling and extrusion mills. With over 80 years of manufacturing experience and significant investments, Sofia Med has evolved into a competitive modern European company with customers globally.

For more information: https://www.sofiamed.com/

Focus on WHISCO

WHISCO specializes in supply chain management consulting services. The company’s mission is to help its customers improve their supply chains by implementing advanced planning, scheduling, and optimization solutions and providing support through project management, consulting, development and training.

For more information: https://www.whisco.eu/