CSADI

Using industry solutions Building Design for Fabrication and Integrated Built Environment, China's Central-South Architectural Design Institute (CSADI) embraced smart construction on the 3DEXPERIENCE platform to create a construction virtual twin of the Wuhan Next Generation Meteorological Radar tower ahead of construction.

Accomplishing design efficiency

More than 10 disciplines such as plumbing and HVAC were coordinated through the 3DEXPERIENCE platform, achieving record-breaking efficiency in design.

- 60%

lower in construction errors

- 30%

faster in construction schedule

Smart construction for an ambitious weather tower

Striking the balance between innovation and efficiency hasn’t always been easy in an industry known for its productivity issues. Yet construction is now finding its feet in a digital world and reimagining how buildings should be designed and built. Architecture, engineering and construction (AEC) companies go beyond building information modeling (BIM) with virtual twins to embed engineering and construction knowhow at the concept phase, and seamlessly connect people, data and workflows.

Take the Wuhan Next Generation Meteorological Radar tower, designed and developed by Central-South Architectural Design Institute (CSADI) in China. Set to play a critical role in the nation’s meteorological disaster monitoring network, this twisting cyclone-shaped weather tower brings to life CSADI’s vision of using advanced technologies to bring together all disciplines in the value chain and refine the design and build in the virtual world before physical construction. CSADI’s ambition is backed by a wider drive in China to embrace smart construction.

“Our vision is to transform into a high-tech enterprise to manage all elements in urban construction,” said Li Ting, chairman of CSADI. “In recent years, China’s construction industry has supported the concept of engineering, procurement, and construction (EPC), and a series of policies drive this concept. In EPC, design takes the lead, and the general contractor integrates all disciplines. By combining product and process design, what was once fragmented project management becomes truly integrated.”

CSADI trusted in the 3DEXPERIENCE platform to bring its connected, smart construction vision to life.

“We must have the best tools if we are to succeed, so we placed our focus on collaborating with Dassault Systèmes and using the 3DEXPERIENCE platform,” Li Ting said. “We needed a pilot project to test its capabilities and the Wuhan Next Generation Meteorological Radar Tower was the perfect fit. It would enable us to see how we could bring all disciplines covering structure, water, heating, electricity and geotechnical engineering within the virtual twin to achieve truly collaborative design.”

Transparency and speed in 3D

Key to the success of a multifaceted project like this is the ability to bring all stakeholders from across the value chain within a single environment so that everyone’s requirements are taken into account and no information gets lost along the way.

“When we shared the 3D model with the general contractor, for example, it became very intricate and precise in detail, but it remained fundamentally the same model,” Li Ting said. “All stakeholders worked on that same model with their individual discipline, making it the first project for us that was based on a single model for its entire lifecycle.”

Dr Zhang Shen, director of the Engineering Digital R&D Center at CSADI, explained the benefit of this continuous data flow: “Our main goal of using the 3DEXPERIENCE platform is to achieve data-driven development and work from a single data source. It enables us to effectively connect the data between design, construction, operations and maintenance, so that we can see exactly what’s happening at every stage.”

Making the switch from 2D drawings to a digital 3D model has been transformational for CSADI.

“The 3DEXPERIENCE platform has been the catalyst for a critical change in our mindset,” Li Ting said. “Back when we were doing things in 2D CAD, every discipline worked in silos creating their own drawings. This often resulted in errors and misaligned priorities – something we can avoid with real-time collaboration.”

Designers shared photo-realistic images of the Wuhan Next Generation Meteorological Radar Tower design with the client ahead of construction.

“We used 3DEXCITE to do the interior design of the weather tower,” explained Yang Hao, an engineer at CSADI. “The output graphics provided a basis for material selection, and helped our customer understand clearly what the structure would look like once complete.”

The 3DEXPERIENCE platform also helped to streamline project management and ensure that all stakeholders were assigned the right tasks at the right time, with access to the role-based functionality they need.

“We’ve used ENOVIA on the 3DEXPERIENCE platform to coordinate more than 10 disciplines such as water/plumbing and HVAC, and issued different permissions to different personnel,” Yang Hao said. “The project manager then assigns tasks to the discipline leaders, making the entire process much clearer.”

With this streamlined, transparent approach, CSADI is able to reduce errors and complete the construction stage much faster than before.

“We achieved record-breaking design efficiency,” Zhang Shen said. “All stakeholders can see each other’s updates to the model in real time, allowing us to improve design efficiency by nearly 30%. Having the design and construction plan within the same model avoided misinterpretation and guesswork by the contractor, which reduced the error rate in the construction process by nearly 60%. The entire construction schedule was completed nearly 30% faster.”

Reduced building complexity and cost

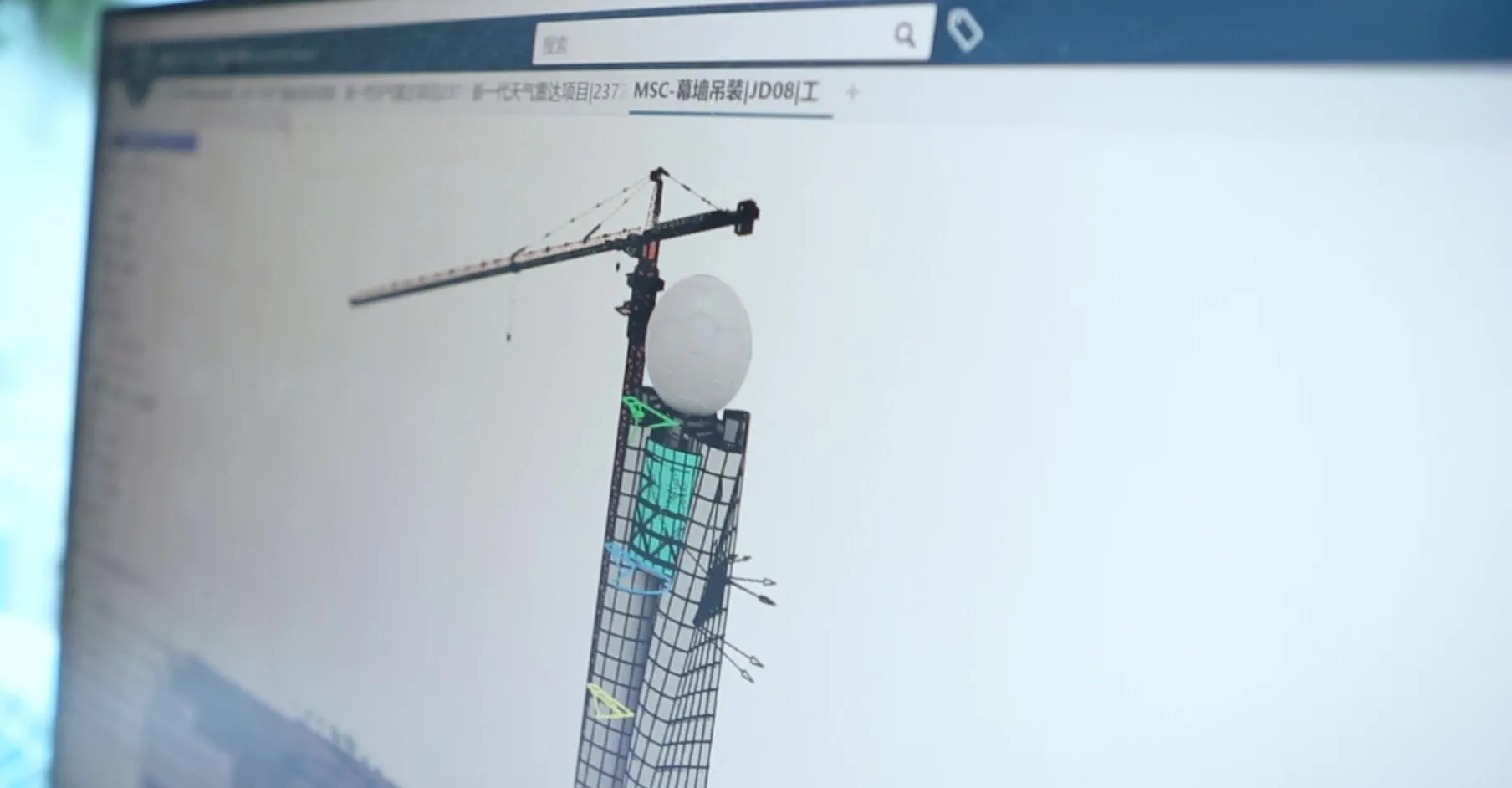

The Wuhan Next Generation Meteorological Radar Tower is not a typical tower. Inspired by a cyclone, the outer façade twists in a double spiral. The sophisticated design was optimized digitally using CATIA on the 3DEXPERIENCE platform, helping to determine the perfect rotational angle of the building and accurately calculate the shape and dimensions of over 1,000 glass-fiber reinforced concrete exterior wall panels. This reduced the construction difficulty and cost.

“The shape of the Wuhan Next Generation Meteorological Radar Tower project itself is quite complex; it is a hyperbolic curve that imitates a dancing duo,” Zhang Shen said. “CATIA allowed us to determine the optimal 18-degree angle for the twisting shape of the building.”

For such a complex design, a precise 3D model was invaluable to show the contractor exactly what the final result should look like – and how to get there. CSADI uses CATIA to create detailed, parametric models for all disciplines covering architectural, structural, mechanical, electrical and plumbing, and façade engineering. This supports generative configuration and variant management.

“We collaborated with the construction contractor using the model to fine tune the design, and incorporated the rebar, steel structure, facade and construction procedure model in a unified manner,” Zhang Shen said. “We were able to demonstrate exactly how things should be done.”

Our main goal of using the 3DEXPERIENCE platform is to achieve data-driven development and work from a single data source. It enables us to effectively connect the data between design, construction, operations and maintenance, so that we can see exactly what’s happening at every stage.

Simulation before construction

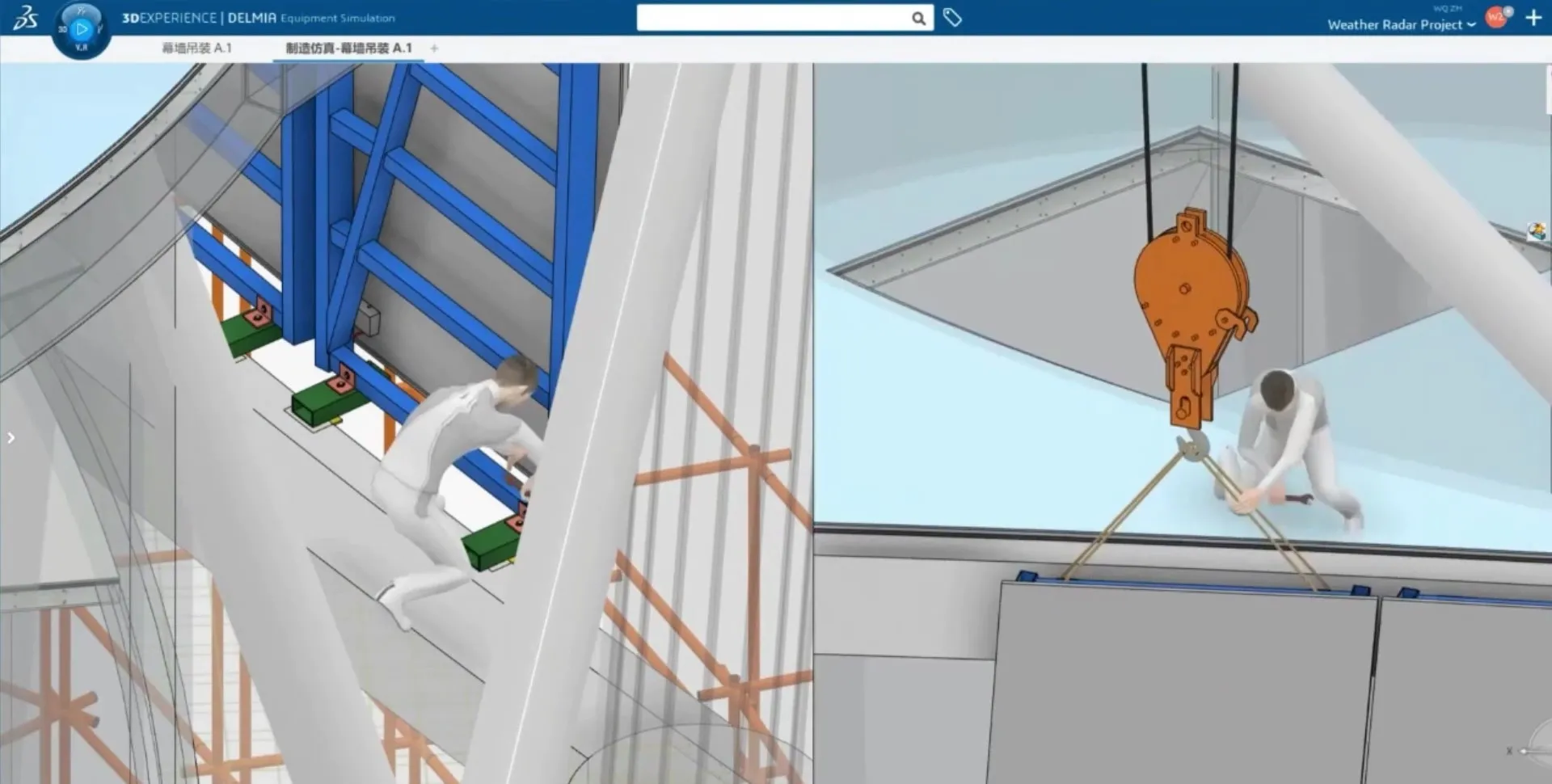

The ability to refine the design of the weather tower and simulate how it would be constructed in the virtual world has helped to remove any unknowns from the construction stage. This has saved CSADI time and money.

“We used DELMIA to create a virtual twin and simulate the construction process and automated equipment,” Zhang Shen said. “This allowed us to test and verify everything before construction to ensure that all work orders were clear and the process was foolproof.”

These simulations have been critical for ensuring worker safety during construction too.

“One aspect we simulated was the hoisting of the facade components in the installation sequence,” Yang Hao explained. “The simulation took into account specific scenarios including the location of suspended platforms, obstructions and wind calculations, helping to determine the ideal conditions for workers to safely install the facade.”

Smart data management

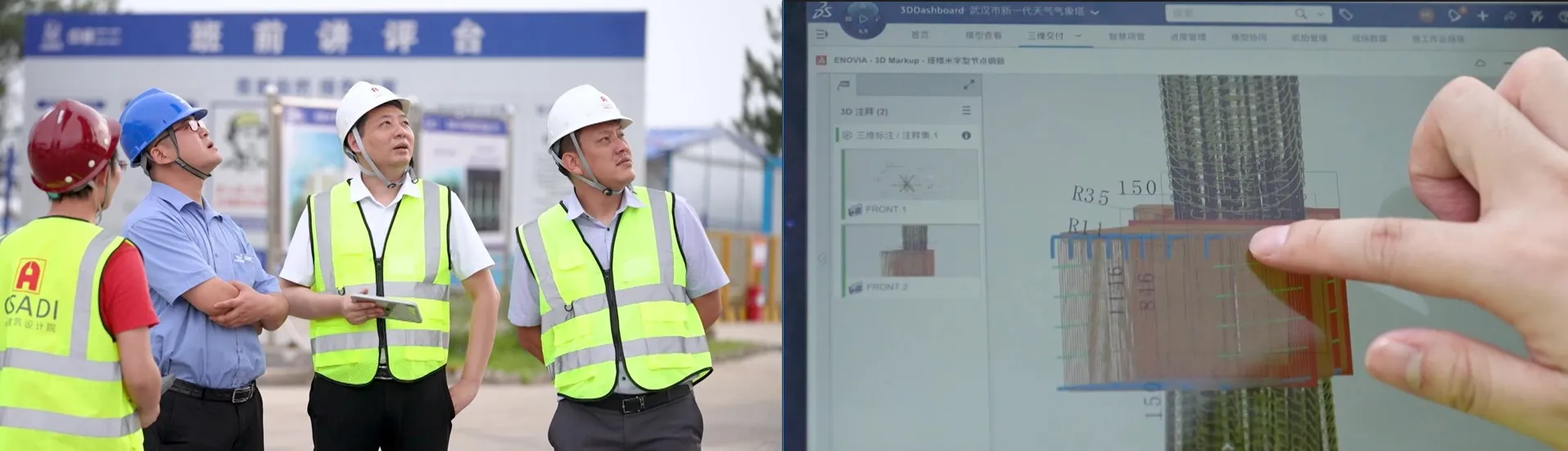

Embracing smart construction methods means that CSADI must find ways of managing the vast amounts of data it now generates. CSADI stores all its data and knowledge templates using ENOVIA on the 3DEXPERIENCE platform.

“Making the transition from 2D engineering drawings to 3D digital models requires a lot of work,” Li Ting said. “There’s a huge amount of information to incorporate and display clearly in the 3D model, including dimensions, materials, cost and process information. It has led us to create our own model-based definition for a construction virtual twin on the 3DEXPERIENCE platform. With this, we believe the journey to digital construction will be greatly accelerated.”

“Already, we’ve accumulated significant knowledge through the 3DEXPERIENCE platform, and our template library is growing, which will enable us to get new projects off the ground faster,” Yang Hao added.

CSADI also takes advantage of tools such as NETVIBES to manage all construction related data and view it in clear dashboards.

“NETVIBES has helped us to effectively coordinate our construction process, construction progress management and construction quality management data,” Zhang Shen said. “The contractor can bring in all the data it needs within the context of the 3D model. This will be of great help in the future as we continue to develop our smart construction process.”

Commitment to the 3DEXPERIENCE platform

For CSADI, this is only the beginning. The company is now looking at how it can use the 3DEXPERIENCE platform in other projects and develop industry standards for using the technology to achieve even greater levels of efficiency.

“From here, we hope to eventually use the same 3D data models to drive the automated machinery in prefabrication factories,” Zhang Shen said. “This will significantly transform our entire construction industry.”

As the company looks to the future, it plans to use the 3DEXPERIENCE platform to strengthen its smart construction capabilities.

“Together with Dassault Systèmes, we have made major progress,” Li Ting concluded. “CSADI must now seize this digital opportunity and become a leader in our industry. With help from Dassault Systèmes, we can reinvent ourselves and transform from a traditional engineering consultancy into a high-tech EPC enterprise.”

Discover more about the Building Design for Fabrication industry solution experience.

Discover more about the Integrated Built Environment industry solution experience.

Focus on Central South Architectural Design Institute

CSADI, founded in 1952, is one of the earliest established comprehensive architectural design institutes in China. It is recognized as one of the “Top 100 Survey and Design Enterprises in China” and “100 Contemporary Chinese Architectural Designs.” CSADI focuses on providing its customers with whole process technology and management services for construction projects, covering everything from architectural design, urban planning, municipal engineering, BIM design and consultation, green technology design, project management and general contracting.