Austrian machine builder automation.eXpress streamlines processes with Dassault Systèmes’ cloud-based Digital Equipment Continuity industry solution.

automation.eXpress

With the amount of people who work on a singular project, having one unified platform is essential for collaboration.

I would say that we are 25% more efficient.

The special machine builder pushing the boundaries of automation

The concept of automation is not a new one. For years, industries like automotive, metal processing, packaging and mechanical engineering have benefitted from the help of automated solutions that keep their major processes up and going.

For the Austrian startup automation.eXpress, automation is at the center of the work they do each day where they build special machines - semi or fully automatic machines that carry out specific, monotonous tasks like assembly, packing, or machining.

“Our customers come to us with a request for a machine that has never been created before. They have no idea how it will work, the parts required, or how it all comes together. More or less, it’s a blank sheet. Our team is faced with the challenge of developing and designing a highly complicated machine from scratch.”

automation.eXpress believes true modern automation goes far beyond traditional solutions of the past and is dedicated to creating highly intricate, custom-made solutions that are flexible, precise and future-proof for their clients. How are they doing it? With the 3DEXPERIENCE platform on the cloud.

“The 3DEXPERIENCE platform fits perfectly for our process and our mission,” said Daniel Schöpf, Founder and CEO of automation.eXpress.

3D modeling to showcase the complexity of automation and win sales

Creating a special machine that transforms a manual process into smart automation is no easy feat. “It is really complex to design these types of machines. Take, for example, a palletizing machine. When a human handles this task, the brain and all senses are active; you think about where to grab different parts and you use your eyes to decide where to place them. You feel if, for example, there are some bumps and carry it differently. When a machine performs the same process automatically, it’s much more complicated. You need cameras, robots and sensors,” Schöpf said.

Consider a conveyor belt system. In a manual setup, it might look like this: Parts are taken off the conveyor by hand, parts are manually placed in boxes according to descriptions, visual inspection is carried out by humans and cycle times are unpredictable.

An automated conveyor belt system is far more complicated: Parts are taken off the conveyor by a central 4-axis robot and piled up, the parts are taken and placed in a mesh box by a 6-axis robot, empty boxes are automatically moved to the loading place by robot, cardboard inlays are automatically inserted by a vacuum packer, quality checks are performed by 3D sensors and cycle times are consistent.

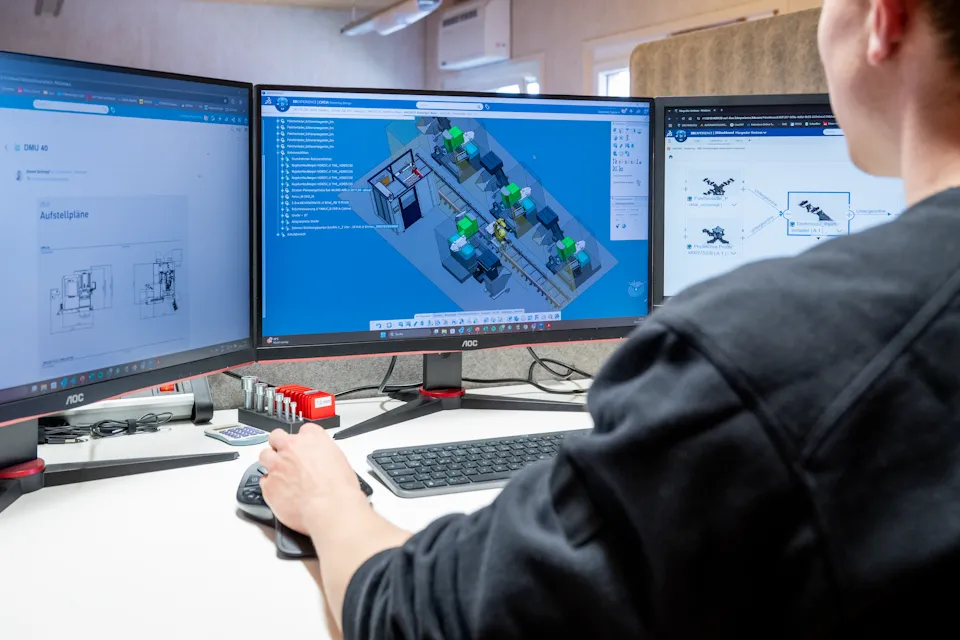

Showing how all of these parts on the special machines seamlessly come together to perspective clients is integral in the sales process. “While other companies make proposals using simple sketches and present them, we use the 3D modeling capabilities powered by CATIA on the 3DEXPERIENCE platform as our unique selling point,” Schöpf said.

“Actually, we start directly with the concept creation in 3D and do NOT wait until we have the purchase order in house. Why? This approach makes it easier to communicate with our clients as they can already see their machine and how it will look like. This helps everyone involved at the customer site in the buying decision and it evokes emotions. With CATIA, we design what the final special machine will look like and how it will work– right from the first discussion and exchange we had with the customer.” Schöpf said. “The first purchasing manager I ever worked with said, “This looks realistic and I trust you. You have the job.” I won my first sale on my pitch alone.”

Schöpf says the 3D model is the backbone of their organization’s process. “Once we win the deal and the sales order is finalized, the 3D model is shared as a concept with the design and engineering department. Then, a 3DSwym account on the platform is created related to the specific project. From there, all information is documented in 3DSwym and all team members have access to the 3D model.”

By using the 3DEXPERIENCE platform, automation.eXpress is able to reduce the design effort per order, lower risks and shorten the offer time - thanks to distinctive 3D models available already in the sales process.

Seamless end-to-end project management on the 3DEXPERIENCE platform

When Schöpf was searching for the right platform for his employees, he consistently came back to three pain points that have followed him throughout his 20+ career in the industry.

“I have been doing special machines for 20 years and there are three big challenges I’ve witnessed in the industry. The first is a lack of non-transparent data. Every employee should have access to the same data. The second is being limited within the system you use within your company to design, engineer and manufacture the special machines. And third, is a lack of productivity. If you are not efficient, you are losing money, wasting time, and creating unnecessary problems,” Schöpf explained.

“The 3DEXPERIENCE platform checked all three boxes” Schöpf confirmed. He credits its efficiency to the fact that when you use the 3DEXPERIENCE platform, everything is digital and a unified environment. “We don’t have to use any outside systems and can easily access 3D models from our mobile phone or any device,” says Schöpf.

All departments at automation.eXpress are using the platform, from the mechanical and electric engineers to those in sales and human resources. With CATIA, designers leverage 3D modeling tools to imagine new special machines, ENOVIA is utilized for day-to-day management and collaboration, and DELMIA’s Work Instructions Planning brings special machines to life with comprehensive 3D process and resource planning tools.

“This one platform is the master of everything which is very important for our efficiency. There are no excuses such as “I don’t have this data” or “I don’t have the most recent information.” Data is for everybody, anywhere, at any time,” said Schöpf.

The entire team at automation.eXpress finds the process of moving from the design stage to the manufacturing and production stage seamless due to the platform’s data transparency. “In production we have to assemble the machine. There is no paper in our production. Everything is 3D model-based, so all of our employees have access to the data,” Schöpf explained.

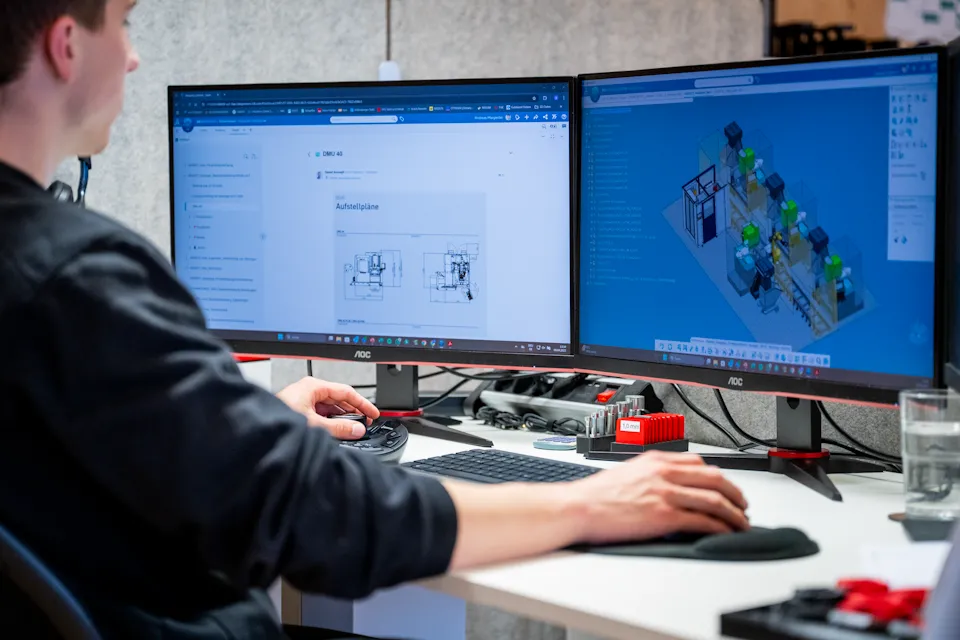

Inside the automation.eXpress facility, employees collaborate seamlessly across departments using the 3DEXPERIENCE platform, turning complex machine concepts into fully realized automated solutions.

Greater data transparency, efficiency and productivity for all

Every department at automation.eXpress relies on the 3DEXPERIENCE platform to execute tasks needed required to build a special machine. Project managers begin their day by checking notifications and responding to anything pertinent. Then, they access the designated project dashboard they are working on. Using 3DViewer they verify if the design department has implemented changes that have been discussed and review timelines, see who has been assigned to what, and create new tasks. They can view the entire project from a bird’s eye view.

Building a special machine is a huge project with many moving parts, but the 3DEXPERIENCE platform has provided the team at automation.eXpress with the resources needed to work with more efficiency than ever before.

“With the portfolio on the 3DEXPERIENCE platform, you have access to different processes in a single place. Normally you have 5 to 6 parallel worlds in an organization. You have an electric world, you have a software world and an assembly world. With the portfolio on the 3DEXPERIENCE platform, you have huge access to different processes but it is all on one platform,” Schöpf said.

This in return leads to greater efficiency. By leveraging the platform, automation.eXpress has reduced engineering effort per order, limited technical and commercial risk and shortened quotation time. “I would say that we are 25% more efficient. With the amount of people who work on a singular project, having one unified platform is essential for collaboration,” said Schöpf.

And while other organizations often have data security concerns about the software they use, partnering with Dassault Systèmes has given them the confidence to continue using the 3DEXPERIENCE platform for years to come. “Data security was a concern. However, when I work with Dassault Systèmes, I’m confident data is handled with care according to local regulations,” Schöpf said with conviction.

Today, Dassault Systèmes business partner TECHNIA is supporting the company with onboarding and implementation and automation.eXpress’s entire workforce uses the 3DEXPERIENCE platform on the cloud for sales, project management, HR, design and engineering.

As far as the future, the company plans to work with Dassault Systèmes for years to come and even has hopes to onboard its own customers to the platform so that they, too, can reap the benefits of working within a virtual twin experience. “For the future, I’d like our customers to benefit from this efficiency booster the platform offers. This way, our customers can navigate the 3D model, select the spare parts needed and order them directly – quickly and easily via the 3DEXPERIENCE platform.

For Schöpf, the reason to continue this partnership is simple. “Dassault Systèmes helps me to be the best on the market,” Schöpf beams with pride.

Discover more about the Digital Equipment Continuity industry solution experience.

Focus on automation.eXpress

automation.eXpress develops special machines that set new standards. With the unique AX Intelligence design process, they create groundbreaking automation solutions that make the future tangible today. They provide loading and unloading technologies, assembly lines, and customized mechanical engineering to a wide range of sectors, including automobile, metal processing, and chemical/pharmaceutical.

For more information: https://www.automation.express/en/

Focus on Technia

By combining its customers’ strengths with its experience in product lifecycle management, TECHNIA helps turn vision into value. Its solutions are used worldwide in industries such as life sciences, automotive, travel, retail, offshore, telecom, fashion and food and beverage. It serves over 4,000 customers worldwide, including 43 that are listed on the Fortune 500.

For more information: http://technia.com/