Line Building: Leverage Virtual Twins to Integrate Your Robots into a Line

Virtual twin technology gives robotics startups the ability to integrate their innovation into new or existing manufacturing lines before any physical element comes into play, reducing risks and costs. With its capacity to design, simulate and virtually test, the 3DEXPERIENCE platform on the cloud gives the possibility for startups to meet customer demands faster while keeping up with new trends and overcoming current challenges.

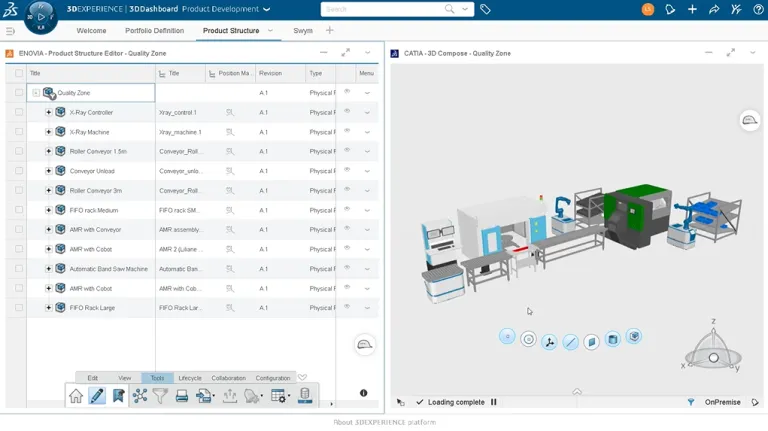

Create production line mock-ups that meet customers’ requirements

Provide a quick and accurate response with a configurable solution

Robot providers need to respond quickly to call for tenders to maximize the chances of securing a purchase order. Apart from speed, it is important to ensure the line meets performance requirements. How can Virtual Twins of manufacturing help robotics companies?

Robot providers are using the 3DEXPERIENCE platform on the cloud to create digital replicas of their robots, their behavior and how they can integrate into the factory lines for their clients. In doing so, they can showcase how their innovation is going to operate within a line and which problems it is going to solve for their customer.

Virtual twins give them the ability to design, simulate and virtually test the production line before any physical element comes into play. A configurable solution that will eventually allow them to multiply their possibilities, speed up validation and reduce risks and costs not only for their clients but also for them to suit the limited budget and small workforce of startups.

Meet new trends and challenges

In today’s market, the robotics industry is becoming more competitive. With new trends emerging almost every day, companies need to be ahead of the competition and have access to cutting-edge technologies that will help them do so.

Autonomous Robots

AGVs and AMRs are increasingly used in production lines to improve flexibility. How can line builders include this technology in their simulation?

VR Experiences

The robotic industry is highly competitive. It can be hard to stand out, especially for startups. How can robotics startups leverage VR experiences to provide their client with a clear understanding of their added value ?

Human-Robot Collaboration

Human-robot collaboration is an increasingly used approach. But the safety of the operator must be assured. How can line builders make sure the workcell is safe using sensors?

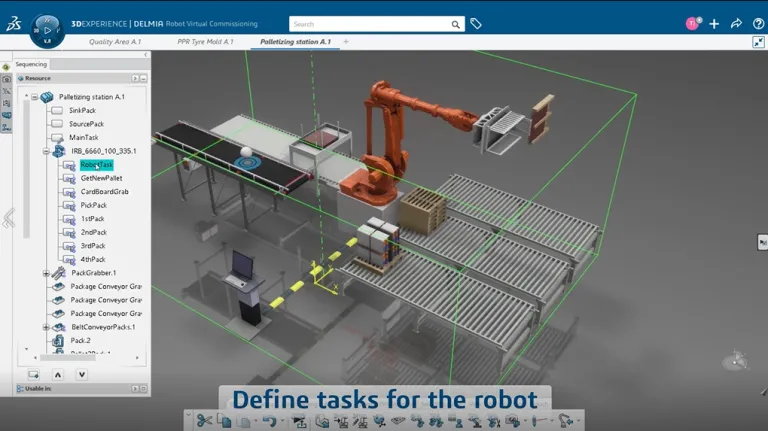

Create functional robotics workcells, reduce commissioning time

Programmers leverage the 3DEXPERIENCE platform on the cloud to program high-quality workcells more quickly. This allows them to simulate and validate assets while reducing commissioning time.

Commissioning a line can be a lengthy and costly process and mistakes are often caught too late which causes project delays. With virtual commissioning, the production systems and robotic behaviors are modeled and tested virtually before physical commissioning, allowing for faster development time and lower costs.

Our customers can now see a complete simulation of their production line upfront and know exactly how their investment will pay off. It’s bringing us much closer to our customers.

Learn more

Ready to learn more?

See how the 3DEXPERIENCE platform on the cloud can transform the way you design and produce your robots.