How Can Eco-Design and Lifecycle Assessment Advance Sustainable Innovation?

Learn all about eco-design and lifecycle assessment solutions in manufacturing with Dassault Systèmes sustainability expert Amaury Péau.

Designing Impactful Innovation podcast - episode 7

In this episode, Dassault Systèmes sustainability expert Amaury Péau tells us everything there is to know about eco-design and lifecycle assessment solutions in manufacturing.

What is eco-design? Can lifecycle assessment solutions help manufacturers apply an eco-design approach and develop more sustainable products? Tune in to find out.

Meet our speaker

It is the data that drives innovation. To be able to make comparisons, analyze, understand and improve a product, we need data.

You can follow the "Designing Impactful Innovation" podcast on Apple podcasts, Spotify, Deezer, YouTube or by RSS.

Stay tuned!

Read the transcript

Clara: Hello and welcome to the Designing Impactful Innovation Podcast. I'm Clara, your host and today we're talking about how eco-design and lifecycle assessment tools can help us develop products more sustainably. I'm joined by Amaury Péau, Worldwide Sustainability Associate at Dassault Systèmes.

Amaury: Yeah, of course. Hello Clara and thanks a lot for the invitation. It’s always a pleasure to talk about eco-design and sustainability.

So more personally, my name is Amaury Péau. I have always been passionate about these topics and I wanted to combine my personal interests with my professional interests and act for the improvement of our society. It is with this goal in mind that I joined Dassault Systèmes two years ago as a sustainability solution specialist and my role today is to accompany our customers, to give them the keys to become more sustainable and to work jointly with the relevant internal stakeholders to define the right offers and solutions to develop.

So today, still with the same roles and missions, I work within the corporate sustainability team in the customer engagement pillar.

Amaury: So yeah, I think that today creating more sustainable products is indeed an objective for manufacturers. There are several triggers for me.

First, I would like to point out the growing importance of sustainability in our society. As consumers or as professionals, we are all actors of the transformation. Today, most of us are aware of the importance of the evolution of our society.

We have all observed the catastrophic events of the last months and years, such as heat waves and floods. It is no longer possible to deny all these extreme events. We all know that it is our duty to act in favor of our environment to have a livable and sustainable ecosystem. So this awareness of the current challenges leads to other elements.

We see that consumers want more and more transparency on what they buy. They wish, for a great number, to consume better. In this sense, the regulatory authorities are also aware of the current issues and are trying for the best in accordance with the desires of consumers to establish standards and laws pushing manufacturers and companies to be more transparent and more sustainable.

It is also important to highlight the desire of companies to become more sustainable. We have good examples in France of companies that did not wait for regulations to invest evenly in the circular economy and sustainable development. So today the major challenge of this topic is to obtain environmental data. We see more and more this desire and need for collaboration between manufacturers and their supply chain.

One of the keys to this systemic change is access to data, because without data it is not possible to have a real knowledge of the environmental impact of a product. Nor is it possible to compare products between them without a valuable point of comparison. So concretely, to be able to meet this need for transparency, it is necessary to be able to quantify the environmental impact of the product over its entire lifecycle.

And it is true, by obtaining and calculating the impact that it would be possible to establish a real eco-design approach in the product development cycle. And this way of calculating the impact has a name, it is lifecycle assessment – LCA – and it is a tool for eco-design.

Amaury: So eco-design is an approach, a way to think. It is to take into account the environmental impact of the product from its design phase. The ISO 14,006 standard defines eco-design as the integration of environmental aspects into product design and development, with the aim of reducing adverse environmental impacts throughout the product's lifecycle.

And these objectives are pursued while ensuring that there is no degradation of technical performances. This approach can be seen as designing products that last longer but have less impact. Products that are more easily dismantled. Products that consume less energy. The use of renewable materials or the lightweighting of certain parts of a product. Eco-design is really about developing a new way of designing products, a more sustainable way, and the eco-design approach can be presented in six steps:

- The identification of the stakes and objectives for the company

- The environmental analysis allowing to set a baseline on reference products targeted by the eco-design project

- The search for eco-design solutions – evaluating the different eco-design alternatives

- The comparison of the different alternatives to support the final decision

- Then a comparative analysis of the eco-design products with the reference product to quantify the reduction of the environmental impact

- And finally, the market launch.

So these are the six different steps of an eco-design approach.

Clara: So steps from upstream to downstream, right?

Amaury: So in fact, you are right. Eco-design being an approach, there are several potential tools to implement this vision. We can think of guidelines, substance lists, ecolabels, checklists, ecological index matrixes, or lifecycle assessment. And it should also be noted that today, without real data, it is not possible to quantify the environmental impacts of products, and therefore it is not possible to quantify the benefits of an eco-design approach.

So one of the biggest challenges for manufacturers and companies is to know and understand this environmental data. So concretely, upstream in the supply chain, it can sometimes be complicated to have this environmental data. OEMs can know their products and components very well. But to have an idea of the real impact of products, it is necessary to go up the value chain. And this from the small manufacturer, where some build a part of the product and know its assembly process to be able to evaluate it from an environmental point of view. So today the challenge is to share information and data. And it is a challenge because it is the data that drives innovation. To be able to make comparisons, analyze, understand and improve a product, we need data. Without data, we can’t justify.

And this is also why LCA, lifecycle assessment is the most adapted tool when we talk about the eco-design approach. LCA is a scientific method, rigorous, based on real data and recognized databases.

Amaury: So manufacturers should adopt this methodology because LCA is a standardized and quantitative method to assess environmental impact. And according to ISO 14,040, lifecycle assessment is the compilation and evaluation of the inputs, outputs and the potential environmental impacts of a product system throughout its lifecycle.

So it is a comprehensive assessment tool based on four main principles. LCA is objective-dependent, you need to define the “why” you conduct an LCA and the results will depend on that. Then, LCA is function-oriented, meaning that you need to define a functional unit, or in other words, the service provided to the end user. And last, the LCA approach is multi-step and multi-indicator, the impact is assessed at each stage of the product lifecycle from material extraction to end of life and several other indicators.

So to be concrete, LCA is a holistic and multicriteria quantitative approach, taking into account the studied item and its entire ecosystem through its lifecycle. So LCA gives the keys to avoid making decisions that are leading to production shifting. And the process is based on, again, quantifying ingoing and outgoing flows linked to operations or activities at each stage of the lifecycle and translating those quantities in a set of indicators measuring their impact on the ecosystem.

And it is by using this data and translating it into impacts that we can analyze the environmental footprint and understand it. So then, by proposing design alternatives, materials, manufacturing processes and others, we are entering into an eco-design approach. And this is the first part of my answer.

Secondly, there are several reasons why manufacturers should implement eco-design.

First of all, clients and consumers' awareness and expectations are rising. They expect committed companies and sustainable products and services with lower environmental impact, a longer lifespan, lower energy consumption, new functionalities, and also safe components and materials.

So related to this, there is also another point which is the transparency of information. Today's consumers are more and more educated on this issue and are looking for honesty.

So let's take a concrete example: electric vehicles. So, consumers know that EVs are less sustainable than they appear. And we know that the use phase of the vehicles has no direct impact because they don't use fuel. But all consumers know that the batteries are very impactful in terms of raw material extraction and in terms of end-of-life.

So there is also another thing to take into account that the consumers are not always aware of, and that is the production of electricity to charge the battery. And indeed, electricity produced in Germany or in the USA does not have the same impact. There can be a big difference depending on the energy mix. We can therefore talk about indirect environmental impact during the use phase of the electric vehicle.

Then, there is another reason: the regulations. Over the past 15 years, in order to reduce the environmental impact of our activities, the European Union and other public bodies have implemented laws on packaging, energy, environmental labeling in order for industries to integrate eco-design into their product development processes.

So either companies anticipate these needs, being sustainability leaders in their industry, or in the end will be forced to comply with these regulations.

Clara: You talked about data and also about the higher expectations from consumers and regulators for more transparency. I want to come back to the data and go more into detail about this data.

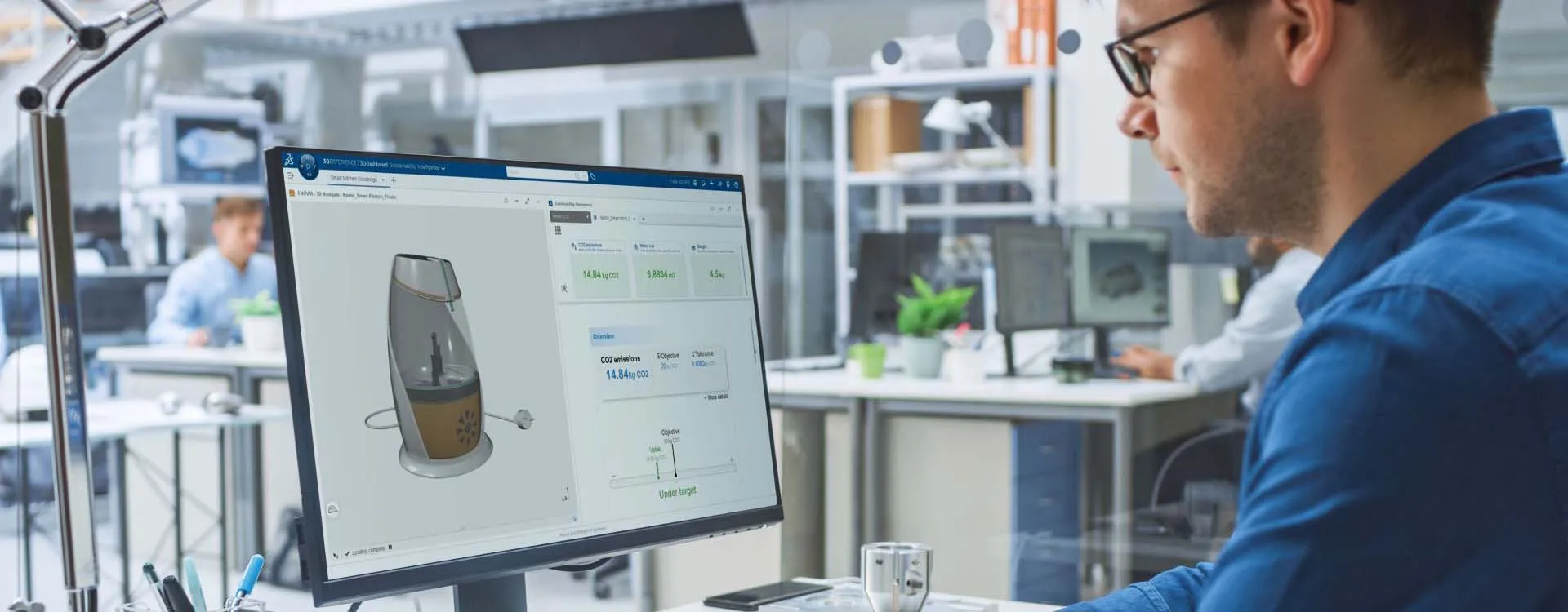

Amaury: Thank you, because it's a very interesting question, this one. So if we take the Dassault Systèmes solution “Sustainability Innovation Intelligence”: the solution has been developed to be compliant with ISO 14,040 and 44, the standard that presents lifecycle assessment. So through this tool, we support various methodologies. You have 3.0, TRACI, EPS, ReCiPe and the IPCC methodology.

And a methodology is a set of impact indicators reflecting the incoming and outgoing flows of a system. They can possibly be normalized, values brought to the scale of a person on a territory and or weighted as a calculation of a single rating. So we have chosen to integrate these five different methodologies in order to offer our users the choice to take the most relevant methodology for them.

And a methodology is chosen when defining the objectives of the study and the level of expertise of the audience. It can also be chosen by the regulatory needs or the geolocation of the study. For example, the European Commission developed the EF 3.0 methodology. It includes 16 different impact indicators such as acidification, eutrophication, land and water use, minerals and metal depletion and others. And this set of indicators is really focused on environmental impact and very complete.

Then we can talk about the building industry. The building industry is an industry using particular methodologies and databases in connection with regulations. So therefore, there are a lot of methodologies and specificities depending on the industry or sector of activity. And in fact, with the lifecycle assessment, we can measure what we need depending on the context and the objectives of the study.

Clara: So we can measure a lot of different things with lifecycle assessment.

Amaury: Thanks for this question. So historically, it should be noted that LCA are done after the design phase, when the product is already on the market. This means that it is not possible to rework on the product and improve it. It is rather an informative LCA to know the impact of the current product, but not to improve it. Our specificity is in several forms.

So first, we integrate the ecoinvent database, which contains more than 18,000 datasets on human activities, processes, materials and others. And we articulate this database in the context of the virtual twin. This allows us to highlight the digital continuity between the lifecycle assessment and the virtual twin, which is not done on the market.

And doing a lifecycle assessment in the context of the virtual twin allows several other things. For the first one, to enforce sustainable goals to drive innovation by putting a sustainability-driven approach with targets, challenging all projects in order to contribute to corporate sustainability objectives. Through our tools, you can leverage the company IP and accelerate innovation. You're going to enrich the LCA results with captured corporate environmental knowledge and reuse products' environmental data throughout the value chain and across projects.

And in addition, something that is very interesting about the lifecycle assessment in the context of the virtual twin is that you can do multi-dimensional tradeoff studies to elect the best alternative. You can take informed decisions between the various alternatives in the early design phase based on always up-to-date environmental matrix assessments.

To conclude, I think that the assessment and introspection capabilities in 3D in context of the virtual twin during the early design phases of the product and when it is still modifiable, is the real value of our tool. You can monitor sustainability metrics, evolution and forecast project governance.

Amaury: So for me, virtual twins are the catalysts for sustainable innovation, true lifecycle assessment, and eco-design. Virtual twins allow us to simulate, model and test several designs, several materials, the behavior of the product in its environment and other things. The idea is to enrich the virtual to improve the real. Through the LCA in the context of virtual twin technology, we can have a more systemic approach and have several actors in the product development cycle work together. And thanks to the 3DEXPERIENCE platform, you can work collaboratively on a single environment constituting a single source of truth.

And in fact, the LCA, in the context of the virtual twin, allows you to implement an eco-design approach and to be proactive on this topic. Again, the conventional LCA measures the impact of what has already been done and stands apart from day-to-day business activities, but with advanced digitalization, LCA can do so much more. The integration of LCA within the virtual twin of a product enables the experts and designers to better understand which components have the highest environmental impact from as early as the ideation stage.

And we need to keep in mind that 80% of the environmental impact of a product is determined during the design phase. It also allows us to drastically reduce design cycle times to find the optimal tradeoffs and working collaboratively with all the stakeholders involved within the product development such as the manufacturing or purchasing teams for example. In concrete terms, today the LCA is a tool implemented in the 3DEXPERIENCE platform that allows the data to be leveraged to improve the product before it is even put into production.

And after having done the lifecycle assessment of a product during the design phase, it is then possible to analyze the impact, to propose design alternatives, manufacturing processes, materials and other. And to analyze these alternatives, we are now able to simulate and model the potential benefits of the different alternatives. And this is the strength of the LCA in context of the virtual twin.

Think of the transportation and mobility industry. Imagine a manufacturer who decides to use less materials for his bumper to make it lighter or even to change the materials. There will be a lower impact during the raw material extraction phase, but the bumper will be less solid and will break more quickly. So it will be necessary to have more bumpers over the whole lifecycle of the car and in the end, the impact will be potentially higher.

And this is why it is important to leverage the data through lifecycle assessment in the context of a virtual twin and to simulate and model the potential benefits of the alternatives, articulating the rest of the solutions and brands proposed by the Dassault Systèmes, such as SIMULIA or DELMIA for example.

Clara: Yeah, that example with the car bumper was really interesting. It shows that you really have to think about a lot of different things, right?

Amaury: Very interesting. So today, I think that virtual twins are already shaping the design and development of the product of the future. The notable evolution that is going to happen and that we are seeing gradually is the sustainability dimension of the virtual twins.

More and more manufacturers and companies now want to integrate a sustainability component into the virtual twin, and this is tending to become the norm thanks to the action of everyone: consumers, companies and regulators. And at Dassault Systèmes, it is our duty to offer the right solution at the right time to our customers to help them become more sustainable.

Our role is to democratize and generalize this principle in the virtual twin and product development, and our goal is to make this virtual twin with its sustainability dimension indispensable to product development. At Dassault Systèmes we are convinced that virtual twin technology represents a great opportunity to enable our customers to create sustainable innovation, which is what I would propose harmonizing product, nature and life translates into.

Clara: Well, this was a really interesting chat Amaury, thank you so much for joining us today on the podcast!

Amaury: Thanks a lot. Thanks again for the invitation.

Clara: Thank you for listening to Designing Impactful Innovation. To find out more, go to www.3ds.com/cloud. Don't forget to subscribe for more insights and stories from our guest experts!

Learn More

Ready to learn more?

See how the 3DEXPERIENCE platform on the cloud can transform your business. Fill out the form to get in touch with our experts.