Sustainable Innovation in Industrial Equipment with Eco-Design and Lifecycle Assessment

Discover how industrial equipment suppliers benefit from adopting an eco-design approach and lifecycle assessment solutions with Dassault Systèmes expert Andrea Cagnin.

Designing Impactful Innovation podcast - episode 11

Join Andrea Cagnin, Industrial Equipment expert at Dassault Systèmes, to learn about how eco-design and lifecycle assessment (LCA) solutions enable industrial equipment companies to improve their environmental impact.

Discover the specificities of the eco-design approach in industrial equipment, what companies expect from eco-design and LCA, the challenges of adopting an eco-design approach and the benefits it brings to companies who make the leap.

Meet our speaker

We are entering an era where the how of the production process is more important than the price of the product.

You can follow the "Designing Impactful Innovation" podcast on Apple podcasts, Spotify, Deezer, YouTube or by RSS.

Stay tuned!

Read the transcript

Clara: Hello and welcome to the Designing Impactful Innovation podcast. I’m Clara, your host, and today we’re talking about the specificities of eco-design and lifecycle assessment tools in industrial equipment with Andrea Cagnin, Industrial Equipment expert at Dassault Systèmes.

Hello Andrea and welcome to the podcast.

Andrea: Sure. Hello everyone. Thanks for inviting me today. So my name is Andrea Cagnin. I'm a business consultant for industrial equipment at Dassault Systèmes. I'm in charge of digital transformation of big accounts – always for industrial equipment – and since I'm passionate about technology and the environment, since 2020, I'm developing the offer that is related to sustainability within industrial equipment.

Clara: All right. In our previous episode, dedicated to eco-design, we talked about the major trends we're seeing in product development today regarding sustainability. Consumers want more transparency, regulators are implementing more laws and norms, and companies need more and more data to adapt to these new demands.

Andrea: That's a very good question to start. From the global point of view, we saw that there are four main reasons to act on sustainability. Let me start by saying that sustainability is not something new, it’s something that is already embedded in current and past corporate operations. It is just that today it's more and more important because of the customer value that sustainability gives.

So we saw four main reasons. The first one is to align with regulations. If our customers do not comply with regulators in terms of material compliance, in terms of energy consumption, in terms of end of life management, they cannot sell the assets. If they cannot sell, they cannot survive. So for this reason, it's important to consider it in the operational processes.

The second one is to drive investment. We saw that more and more investing funds finance just the companies that are compliant with environmental standards. We saw in the past years that companies that were, for instance, related with the oil and gas industry, were not very well seen by certain funds. So this could be a problem even for the future for industrial equipment customers.

The third reason is to attract talents. We saw that, today we are in a context where talents are a precious resource and it's very, very demanding to find the good candidates and to retain these candidates, especially in a context of where the talents are not attracted only by the salary, but also by the meaning of their job. So it's important to provide them with a meaning of their job.

And the fourth reason, I believe it's the most important: is to create commercial value. The end customer considers more and more its environmental impact. I will underline this topic many times during this interview.

So, the final customer takes more importance in its environmental impact and it's crucial to consider this point, to value this point, and to leverage the design, the production of the asset that our customers have to do to improve, to increase commercial value of the product, and then revenue.

So as you can see with these four points, it's really critical to embed sustainability in the early stage of the product development. And it’s for this, that eco-design plays a perfect role. From the industrial equipment point of view, we saw that these four pillars are respected, driving specific challenges within the segments that are proper to industrial equipment.

Clara: Well, that was really interesting. So we have regulations, investment, talent, and commercial value.

Andrea: Good question again. So we know that our customers are driven by financial performances. So they have to create a profit.

And you know what, this is a very win-win situation because the eco-design approach goes in this direction. Having an approach that is related to the environment can improve financial performances. Let me give you an example. By designing an asset lighter, with less inertia, from the early engineering phases, we can reduce the energy used during ownership. So the total CO2 emission can be reduced, and so the cost of the asset during ownership.

Another example could be the raw material used to machine, to design a certain part of the machine. If this raw material can be reduced, the cost of the machine – for instance, for 3D-printed processes – can be reduced as well as the environmental performances of the machine during manufacturing.

So you see, it's a very win-win situation, and it's very important to embed an eco-design approach into the industrial equipment sector. The industrial equipment sector is also a very wide and complicated sector and eco-design is playing a really important role in engineering, manufacturing, operation, and end of life.

Clara: It's interesting that you mentioned the design phase.

Andrea: Yeah, sure. If mechanical engineers, electrical engineers but also industrialization engineers can have an overview of the impact of choosing this material or another kind of aluminum or plastic in the overall performance of the asset since the early phases of the design, this is very important because it could be simulated. They can simulate what the impact is in terms of supply chain. So where to supply that material, what's the environmental impact of producing, transport, and manufacture, that kind of material. But also, how to assemble that part, how to use that part. So there are different topics that are embedded in these questions.

Let me just simplify listing these topics. The eco-design approach can be choosing the right material, could be optimizing quality, could be optimizing supply chain networks. So where the suppliers should be located to withstand target environmental performances…Optimize also inventory stocks with a modularity of mind approach. So how to use parts that have already been designed and manufactured for all the revisions of the machine. So you see, there are different topics in the engineering phase.

But it could also be engineering for maintenance. So how to design machines that could be easier to maintain so the technicians who have to maintain that machine do not have to dismantle 20 parts just to change a belt, for instance. The maintenance will be easier and it has to scrap less parts during maintenance operations. Engineering really plays an important and crucial part during the whole lifecycle of the asset.

As you said, 80% of products’ environmental performance is defined during engineering. And it's for this that this phrase makes the role of the mechanical, the electrical engineer, one of the most dangerous roles in the world because if the work is done correctly, it's something that is very important on the whole lifecycle of that asset, but if it's not done correctly, it could have a huge impact in the following years.

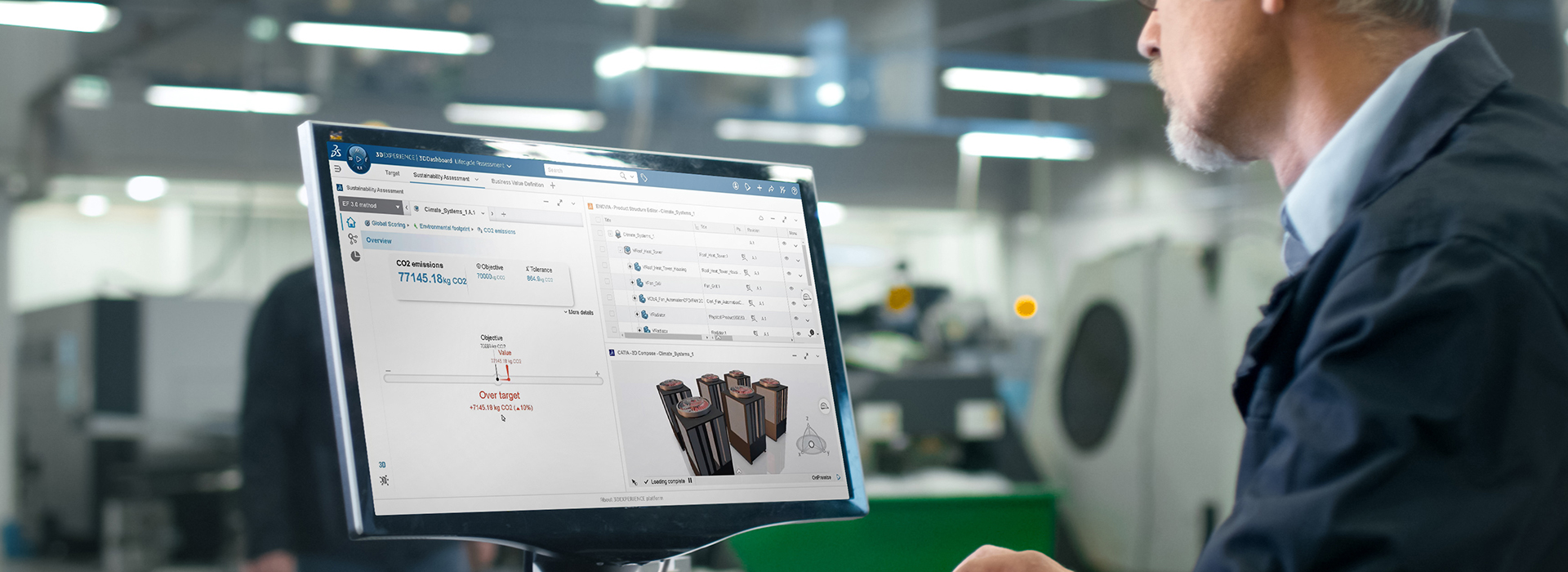

And at Dassault Systèmes we propose to embed LCA, lifecycle assessment, not just for declaration purposes, but in engineering, manufacturing and operation usage. So by using the LCA approach, our customers can make a snapshot of what would be the impact of the design that they are doing. What could be the environmental impact of the production that they are going to set up? What would be the environmental impact of the usage of the asset in a certain way?

So, as you can see, LCA today, it's used for declaration purposes. But what we propose to our customers is really to use this methodology to create scenarios and act in consequence. So to exploit the result of LCA with treated scenarios to improve asset performances in the different streams. Could be engineering, manufacturing, and operation.

Clara: Wow, so that's a lot of things to think about.

Andrea: The first problem of our customers today is the environmental annual declaration that they have to do. So, the first pain is to retrieve information from all suppliers and also their plant to be able to fill a certain database, and then calculate CO2 emission scope one, two, and three, water use, waste produced…

So the main concern today is data collection, but actually this is just the tip of the iceberg from our point of view because LCA can go much farther. As I said before, you can use LCA for declaration purposes for sure, but you can also use it to pilot, to drive engineering, as I said: manufacturing, maintenance, operations, end of life... So it's really important not to see LCA just for declaration purposes, but really like a mindset and an instrument that our customer has to embed in their operation to be able to improve their performances in terms of environmental performances, but also in terms of quality and in terms of financial performances.

Andrea: Yes, so for our customers that have embeded LCA in their operation, the immediate result that they saw is an immediate understanding of the future environmental performance of the assets since the engineering phases. So they do not have to wait a few years to measure the energy consumption, the real energy consumption of the asset to be able to have an understanding of its environmental performance. So this is, I think, the most important point.

Then a second point is that they would be able to reduce energy consumption during ownership. And this, we can do it by working on mechanical engineering to reduce the inertia of rotating parts or to change the design of the asset to be able to reduce electrical consumption peaks. So this is another point that our customers understand and it goes in this direction of environmental performances.

And the third point is about supply chain. So after Covid, we saw that the supply chain context changed a lot. Once, most of our customers had suppliers in China – especially in China – but after Covid the supply chain was disrupted. And so our customers are going to redesign their supply chain network. But this is a very complex and complicated pain, because by redefining the supply chain network they do not know what would be the impact of the supplier change. Our solutions that embed LCA into supply chain operations will allow them to understand what would be the impact of changing, even dynamically, the supply chain network. By having multiple suppliers across the world you can be able to optimize the CO2 emissions by respecting the fulfillment rate.

So, as you can see, this is a new pain that five years ago was not so critical. Today, I think it's the number one, especially for industrial equipment.

Clara: Okay, so you talked about having an immediate understanding versus waiting for a long time, maybe, to have an overview of the future performance of the product in terms of sustainability. You talked about reducing energy consumption and also improving supply chain, right? So, those were the improvements that we can see with lifecycle assessment solutions.

Andrea: All new implementation requires the ability to change in terms of ways of working, in terms of tools to use. So the main challenge today is to embed this new mindset that is to be able to understand and consider environmental performances since the early stage of engineering. So this is the first challenge.

And the second one is that companies have to create these roles: kind of a sustainability engineer, design for a sustainability engineer. So this is a challenge in terms of competencies.

But then the other challenge is also to be able to collect and retrieve all the information that should come from the suppliers. This is a very complex topic, but thanks to our platform we thrive to collect all the information from our OEMs, from their suppliers. Since our platform is something – as the name said, it's a platform, it can collect all information, it can understand, it can track where the information comes from and ease the information sharing between suppliers and OEMs.

Then to finish: the interpretation of the results. Today, the LCA approach is standardized and interpretation is standardized too, but it could be complicated sometimes, especially for new customers that have embedded this methodology. So the challenge here is to be able to interpret the results of the LCA and to evaluate what tradeoff would be the best.

Andrea: Today we are moving from an industrial era where the most important was to produce fast and cheap, to an era where the how of the production process is more important than the price of the product itself and these final customers have understood it.

And today they are more and more conscious of their environmental impact. As we can see in the news when we switch on the television, global warming is something that is on everyone’s minds and it's one of the most important challenges that impact all of us today. And it will impact all of us more and more in the future. This, with the consequence of changing the ways of producing things, to use things, but also the way to buy them and to value them at the end of their lifecycle.

So every minute counts. And it's important to adopt the eco-design mindset from the customer point of view: so how to use things that we buy or that we use – could also be an elevator. How can we use an elevator? But also from our customer point of view, that are the OEMs. So how to design a product, how to manufacture that product, where to manufacture it, how to maintain it, how to use it, how to disassemble to recover some parts of the end of its lifecycle…

So it's very important to have this mindset. And eco-design, embedding lifecycle assessment, is key to enable this change and to overcome environmental challenges that we fixed in different countries in the world.

So you can see Dassault Systèmes is really a key partner and proposes all the tools that would be necessary to be able to improve environmental performances from different points of view, from engineering to manufacturing, supply chain, operation, but also end of life.

Clara: Well, that was super interesting, Andrea! Thank you so much for your insights, and thank you for joining us today.

Andrea: Thanks to you!

Clara: Thank you for listening to Designing Impactful Innovation. To find out more, go to 3ds.com/cloud. Don’t forget to subscribe for more insights and stories from our guest experts!

Learn More

Ready to learn more?

See how the 3DEXPERIENCE platform on the cloud can transform your business. Fill out the form to get in touch with our experts.