The Rise of Digital Transformation in Inventory Management

An increasing lineup of advanced digital solutions have given manufacturers the edge to transform and achieve better inventory control.

Against the backdrop of the Fourth Industrial Revolution, the manufacturing industry is in constant search for new ways to improve its inventory management. From Vilfredo Pareto’s 80-20 principle to just-in-time and pull-based manufacturing, minimizing excess inventory has been a continuous quest.

The United Nations estimated that the pandemic wiped out a total of $50 billion in exports across global value chains, exposing massive gaps in inventory management and global supply chains.

Recognizing the need to build resilience into their existing supply chains to withstand global changes and challenges, manufacturers are spurred to invest more in warehouse automation. An Accenture study estimates that, post-COVID-19, digital inventory management is expected to attract 15 percent more investment in the next five years than previously predicted.

To make a giant leap forward manufacturers need to use digital technology to take better control of stock and manage inventory, starting from system design right down to physical warehouse processes. By improving the material flow throughout the production processes, manufacturers can achieve leaner, more efficient operations.

Reshape Inventory Management with Data Visibility, Robotics and 3D Printing

“A digital warehouse helps a company be future-ready.”

– Mike Bradford

Delmia’s Strategic Business Development Director

Make the shift now towards a fully digital inventory management system. Choose to watch the full video podcast or read the transcript of Mike's insights on how you can achieve efficiency, cut product costs and increase collaboration across your supply chain.

What Are the Four Types of Inventory in Manufacturing That Can Be Optimized?

Getting raw material manufactured into something whole and useful is a complex process, which is why it's crucial for manufacturers to make the right digital investments in their warehouses. Choosing the right digital solutions begins with manufacturers identifying the most common types of inventory used in their plant or warehouse. This way, they can optimize their inventory management for streamlined processes and reduced downtime. The four types of inventory commonly used in manufacturing are:

Raw materials and components

Raw materials are used by manufacturers to create and finish products. Components make up the finished product in a manufacturing process.

Work in progress

This includes raw materials, packing materials, labor and components that are still in production.

Finished goods

These items refer to products that have completed their manufacturing process and are ready to go to market.

Maintenance, repair and operations goods

These goods are part of an inventory of supplies and resources that support product manufacturing or business maintenance.

Reshaping Inventory Management with Three Key Digital Solutions

The three key digital solutions that can help strengthen manufacturers’ approach to inventory management are

Data Visibility

By digitalizing and integrating factories using Dassault Systemes' 3DEXPERIENCE® platform, manufacturers can transform a wealth of detailed data into real-time insights across the entire production process.

Manufacturers can:

- Enhance visibility for better decision-making within their facility and inventory control.

- Create virtual twins of the factory to foresee potential problems in the supply chain.

- Develop more strategic ways to balance supply and demand.

Robotics

With robotics technology such as automated guided vehicles and autonomous mobile robots, manufacturers can obtain fast, accurate and 24/7 warehousing solutions.

The 3DEXPERIENCE platform can help manufacturers design and implement robotics solutions that can automate warehouse systems.

An automated warehouse can:

- Improve operational efficiency

- Increase inventory density

- Lower labor and utility costs

- Speed up order fulfillment

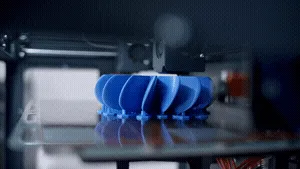

3D Printing

3D Printing enables manufacturers to print parts as and when needed. 3D printing technology on the 3DEXPERIENCE platform can help manufacturers harness 3D printing technologies and realize new manufacturing approaches.

Manufacturers can:

- Cut warehouse downtime

- Reduce Excel-based inventory management

- Streamline storage for parts and components

Meet Changing Demands With Flexibility and Foresight

Laboratoires M&L the manufacturing division of L'Occitane Group, prides itself on sourcing and using natural raw materials. As their raw materials come directly from artisans and farmers, these materials are climate-dependent. To meet the global demand for natural cosmetics, they needed a system to improve their production planning flexibility and deliver high-quality products on time.

Laboratoires M&L used the 3DEXPERIENCE platform to control their entire raw material management process. They gained greater traceability and security from procurement of raw materials, weighing and labeling process, all the way to delivery of the finished products to their boutiques. With real-time output of KPIs and reports of actual on-site activities, production planners had information on production quantity, product availability and raw material procurement’s status.

Control and Clarity With Digital Inventory Management

For manufacturers aiming to unify their inventory management, a digital transformation is the answer. Using the 3DEXPERIENCE platform, manufacturers have superior control over their supply and demand management and inventory flow.

They can make the right procurement decisions early in the production process, perform inventory management without interrupting production and create digital models of their plants to virtually pre-test production lines before physical set-up. With digitally transformed inventory management, manufacturers ultimately gain a competitive advantage in building a future-ready company.

Read our top articles on Operational Optimization

Explore our Industry Solution Experiences

Learn more about how our industry solutions can help you to achieve your professional ambition and business objectives