Texelis

The French manufacturer of axles and powertrains for heavy-duty vehicles needed the agility of 3DEXPERIENCE to grow its capabilities to develop customized products and win more business opportunities with speed and build relevant offerings that demonstrate the added value of its services.

From product provider to mobility solutions partner

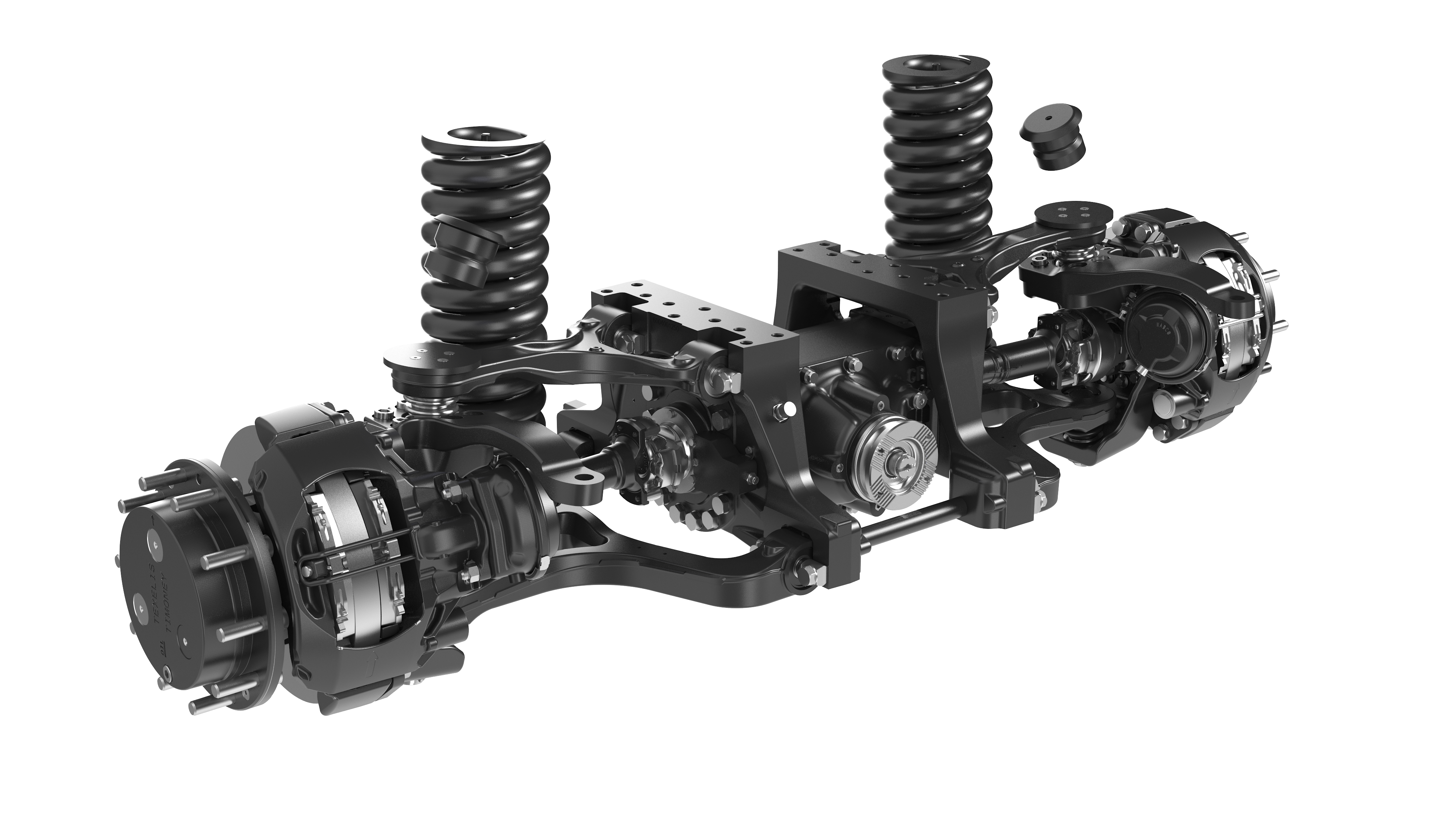

In business since the 1930s, Texelis knows what it takes to be a leading player in the transport and defense industries. The French manufacturer of high-performance axles and mobility solutions for heavy-duty passenger and military vehicles has evolved from a single production site to the mobility partner of choice for customers globally. Texelis constantly embraces innovation to anticipate its customers’ needs as they respond to new market trends together.

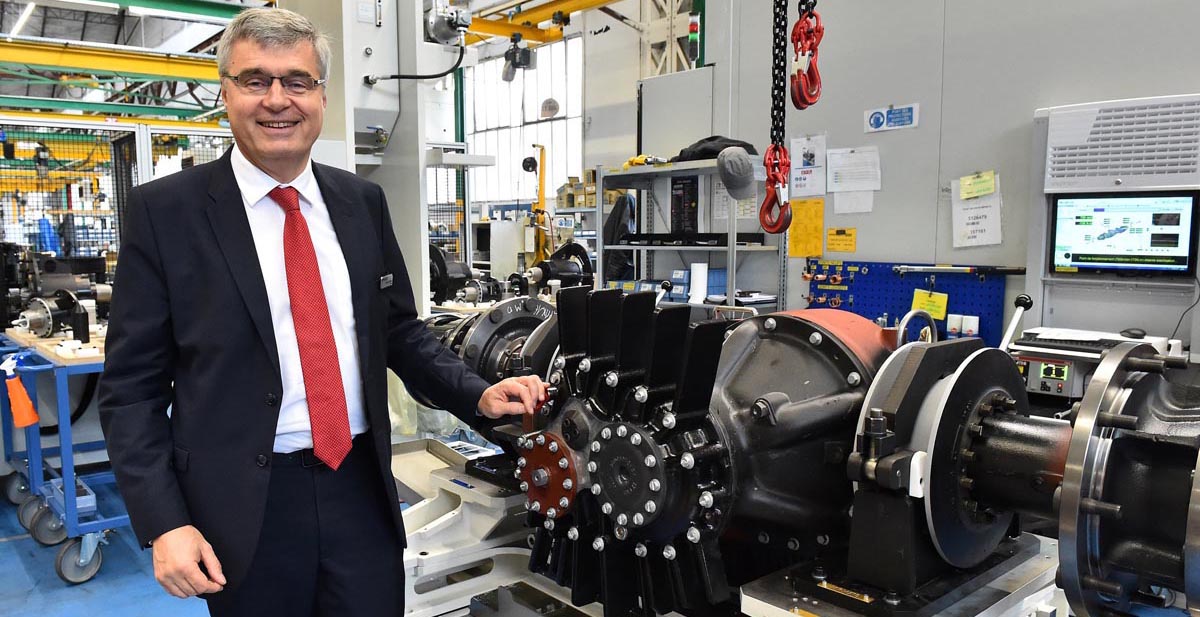

“We’ve always manufactured transmission components, but we broadened our strategy to include mobility subsystems – the entire drive train from the engine to the wheel – and developed our expertise as an integrator to meet our customers’ expectation,” explained Charles-Antoine de Barbuat, chairman of Texelis. “We want to make mobility safe by bringing the right technologies so that all these vehicles, which weigh more than five tons per axle, function and perform well in terms of reliability and passenger comfort.”

Texelis’ evolution goes beyond its product offering. As part of its digital transformation, the company must modernize its production system and the management of its technical data. Its product lifecycle management (PLM) program consists of transforming all of the company’s internal processes to simultaneously handle process design, production and maintenance data, to coordinate internal work and to transmit the right documentation to its customers. Over the past five years, it has also expanded its scope of services to encompass the entire product lifecycle.

“We can supply and design everything from suspension, steering and braking, to Cardan shafts and engine gearboxes,” said Christian Schmutz, digital and collaborative transformation director at Texelis. “When we talk about managing electronic software to control an engine and gearbox, these are new areas for Texelis since we were previously more mechanically oriented.”

This move, coupled with the co-signing of a new contract with France’s Delegation for Armaments (Direction Générale de l’Armement or DGA) in partnership with Nexter to develop the Serval armored vehicles for the French Army, prompted Texelis to review its technology infrastructure and implement the 3DEXPERIENCE® platform.

“We needed to increase our skills in terms of configuration management and operational maintenance,” Schmutz said. “It’s not just a matter of supplying spare parts following a customer’s request, but of being able to manage the entire lifecycle of the vehicle, which requires greater competences. We needed these capabilities as part of our contract with the DGA, driving us to make progress in terms of the management of everything from configuration, traceability and bill ofmaterials (BOM). The 3DEXPERIENCE platform gives us these solutions within a single integrated environment.”

The platform allows us to respond to the urgent need that our clients have expressed in terms of maintenance, configuration management and traceability.

Migrating millions of data

The previous tools in use at Texelis were no longer suited to the volume of data it must handle or capable of supporting it to meet new customer demands.

“There are millions of pieces of data to manage,” de Barbuat said. “Our technical data and monitoring over time has increased by a factor of 20. When the DGA entrusted us with the Serval project, we had to deliver a high level of knowledge of all the components supplied in each vehicle, and monitor all the configurations. We realized that the tools we had were not up to the challenge in terms of volume, nor work processes. We chose the 3DEXPERIENCE platform because of its capacity to handle this amount of data and support collaborative working to meet the DGA’s requirements.”

Before Texelis could take advantage of the 3DEXPERIENCE platform’s rich capabilities, it faced the huge task of migrating all product data from its legacy PLM environment – including previous versions of CATIA and other CAD applications – to the 3DEXPERIENCE platform.

“We had 40 years of product history to migrate, covering around 30,000 files with 26 different formats, which had to be converted to be readable in the 3DEXPERIENCE platform,” Schmutz explained. “We achieved this mass migration in only seven months. Since then, we’ve started to integrate the first functionalities – developing the first modules on everything related to BOM, change management and configuration – and begun to improve our way of working. Now, we use 3DEXPERIENCE applications, but we still have the ability to import CATIA V5 documents into our database. This allows us to exchange files with partners and suppliers.”

Dassault Systèmes and technology partner Visiativ Solutions have worked closely with Texelis to ensure the 3DEXPERIENCE platform meets its specific needs, now and in the future.

“Visiativ was the interface between Dassault Systèmes and Texelis to help us understand how the platform works, and how it can be adapted and translated for our processes,” Schmutz said. “When we design a component, a part, an axle, a vehicle, there are different steps that are carried out and we have to determine how they are managed within the platform. Together, we’ve spent time looking at these business scenarios – the succession of tasks we used to do using our old tools and how we need to do them today in the 3DEXPERIENCE platform. Success involves coaching, training and support debugging any problems we may encounter.”

“We reviewed our working methods in depth to take full advantage of the platform,” de Barbuat added. “3DEXPERIENCE incorporates new standards in understanding project development and can deal with all the dimensions linked to the industrial production part, from the design phase through to the services.”

Importantly, all parties were open to making adaptations so that all users could benefit from the 3DEXPERIENCE platform, including management and operational staff. This involved introducing some additional features.

Throughout the process, Visiativ has supported Texelis to get the most from its investment.

“They have helped us to take advantage of what already exists and change what could be adapted in order to be able to use the solution in the best possible way,” de Barbuat said.

There are millions of pieces of data to manage. We chose the 3DEXPERIENCE platform because of its capacity to handle this amount of data and support collaborative working.

Preparation key to rollout success

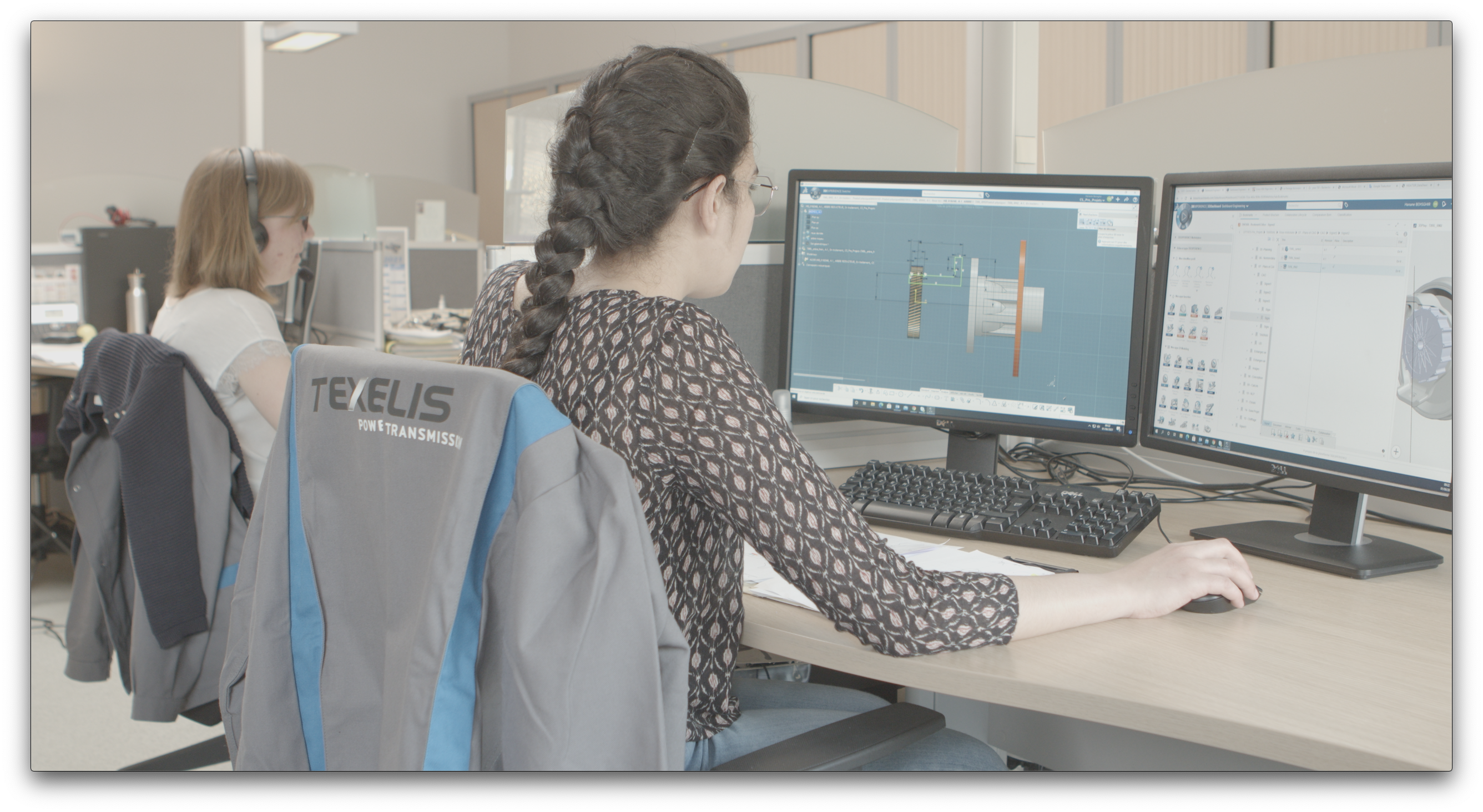

Texelis now has more than 140 users on the 3DEXPERIENCE platform and growing, all of which had to familiarize themselves with the new technology.

“These users had been working with another system for over ten years,” Schmutz said. “They had to be prepared for this change and be trained. They went through face-to-face training in small groups, and we held about 30 to 40 training sessions in total. They were motivated to practice so that on the day of the switchover to the new 3DEXPERIENCE universe, they could make it on their own.”

All this preparation has paid off as people across the business have fully embraced 3DEXPERIENCE.

“We could have heard people say, ‘I’ve lost time,’ ‘It was better before,’ and so on, but in fact, it didn’t happen at all,” Schmutz explained. “This is largely due to the change management we carried out and also the fact that the platform is a user-friendly solution.”

Now that it is beginning to tap into the rich functionality of 3DEXPERIENCE, Texelis looks forward to achieving more profound results across the business.

“The platform allows us to respond to the urgent need that our clients have expressed in terms of maintenance, configuration management and traceability,” Schmutz said. “We also hope to be able to more easily exchange information and communicate better with our partners.”

Security and full traceability first

The concept of passenger safety and keeping equipment in operational condition are essential, especially in public transportation.

“Whenever an incident occurs on a vehicle, we must be able to trace back the whole production line, identify the lot and the system involved to prove that our components have been manufactured with the right conditions, settings and dimensions,” de Barbuat explained. “Each system and its components are individually identified so that, five or ten years after its commissioning, we can find the full history of these systems and ensure that there is no security risk that could affect other vehicles. Through implementing the 3DEXPERIENCE platform, we realized that it was important to deal with all aspects of the product’s life from the outset.”

For Texelis, one of the key strengths of 3DEXPERIENCE is its capability to seamlessly connect the dots among its product development processes, from design to engineering to manufacturing.

“From CATIA, we will generate the engineering BOM (eBOM), and in a few clicks, we can then generate the manufacturing BOM (mBOM),” Schmutz said. “We will have full continuity of information up to the mBOM without having to re-enter data. This is a key element.”

Not only will this save Texelis significant time, but it will enable the company to ensure full traceability throughout the product lifecycle.

“When we deliver a piece or a set of equipment to a customer, we must always be able to say precisely what we have delivered – serial numbers of the sub-components, batch numbers of the parts, quality control documents,” Schmutz said. “That’s so we can trace these components and demonstrate that everything is in line with what was planned to be manufactured. We can ensure the mBOM aligns with the eBOM. ENOVIA on the 3DEXPERIENCE platform allows us to do all that.”

Texelis is also using ENOVIA to build a standard parts library, so that it can create variants of parts for new use cases and speed up product development.

“3DEXPERIENCE is much more cloud-like in the sense that you have a large reservoir into which you put all your data, and it’s all dynamically linked together, which makes updates much more agile,” Schmutz said. “It means you can manage the evolution of your physical product without having to go back in all the BOMs to update them. We create sub-assemblies that are reused for other products, and we use links and keywords to repurpose everything like Lego® bricks. We make new constructions without having to reinvent the bricks every time.”

If we can extend the lifecycle of a vehicle by a decade, then we can also reduce the carbon footprint related to that product. The 3DEXPERIENCE platform will help us to do this [...].

Extending lifecycles, reducing carbon footprint

Concerned about the environment, Texelis integrates the sustainable dimension of mobility into its industrial projects from product design phase. This aligns with the United Nation’s Sustainable Development Goal nine: build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation.

“Our contribution to sustainable mobility is to work on reducing the energy consumption of our systems,” de Barbuat said. “Our products are often used in very compact compartments with little cooling. However, it needs a very high output and to reduce hydraulics and tires consumption. The more we work on the energy efficiency of the bearing part, the more we increase the autonomy of electric vehicles compared to their battery, for example. This is part of our R&D themes.”

“We pay particular attention to the energy savings that we can achieve in our manufacturing processes and beyond,” Schmutz added. “If we can extend the lifecycle of a vehicle by a decade, then we can also reduce the carbon footprint related to that product. The 3DEXPERIENCE platform will help us to do this because we will be able to better manage the range of equipment and vehicles we have delivered through better traceability, configuration and monitoring.”

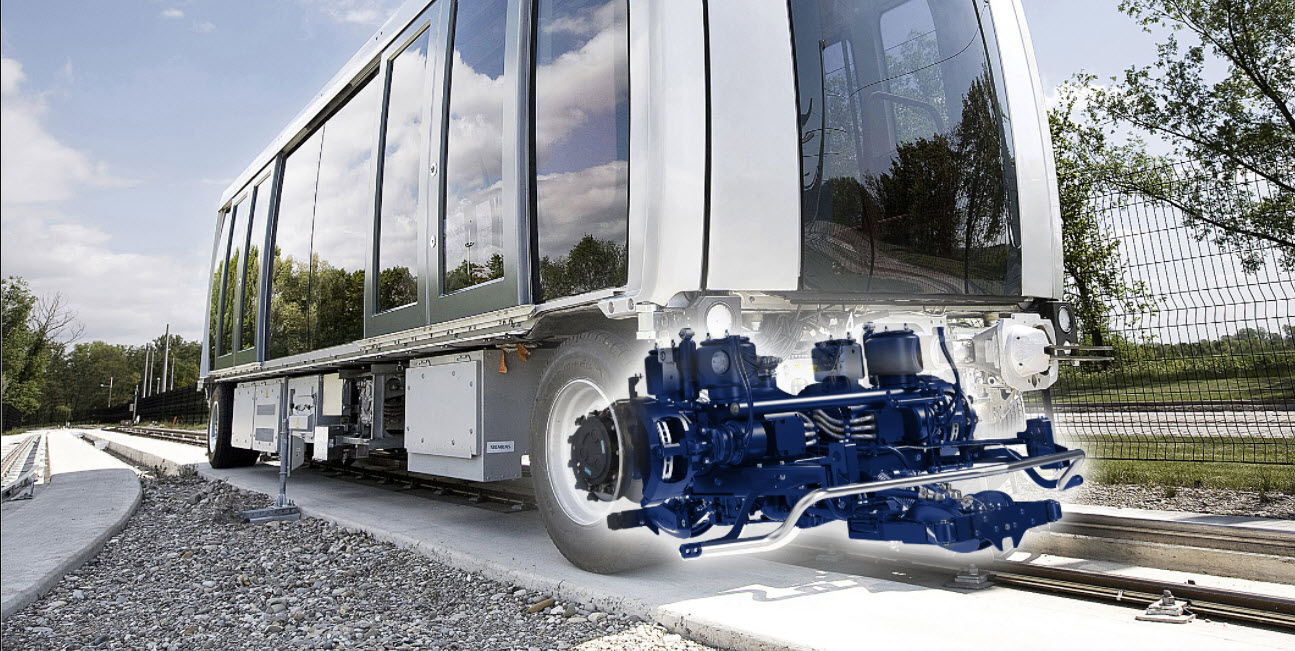

For example, Texelis provides axles for Alstom tramways, which equip the cities all over France. These vehicles have been designed to operate for about 30 years and every ten years they undergo a major overhaul.

“We have a role to play in renovating them,” de Barbuat said. “This means that the axles come back to our workshop and we change all the bearings, gears and seals as necessary. By ensuring this traceability, we’re able to keep equipment in operation a little longer. 3DEXPERIENCE is a solution for conquering these renovation markets. Even more so because there are very few players like us on this market that combine engineering, manufacturing and service skills.”

The company does the same for defense equipment and provides thirty-year maintenance.

“ENOVIA enables us to manage the configuration, obsolescence, and interchangeability of parts, using reference BOMs that are stored and managed in the platform,” Schmutz said. “It helps us to extend the life of these vehicles.”

If I had to take away just one thing, it would be why didn’t we start using it earlier?

An ongoing transformation

Texelis has a clear roadmap for how it plans to extend its use of the 3DEXPERIENCE platform across its business. The first phase was data migration.

“Now we’re moving to using 3DEXPERIENCE for the mBOM and parts configuration,” Schmutz said. “The next step will be to interface with the enterprise resource planning system. Phase two will cover project management, quality documentation management and service BOM.”

As the company looks to the future, it will continue to pursue its digital transformation to achieve long-term success.

“3DEXPERIENCE is opening up perspectives,” Schmutz said. “It’s a company project and must be seen as a strategic solution for the company’s progress. It can make a truly positive impact.”

“What the 3DEXPERIENCE platform brings in terms of services, data reliability across the company, quality, and the ability to position ourselves for new, ambitious calls for tender is quite enormous,” de Barbuat concluded. “If I had to take away just one thing, it would be ‘Why didn’t we start using it earlier?’”

Focus on Texelis

Texelis is a leader in the design and manufacture of high-performance axles and innovative mobility solutions for heavy-duty passenger transport vehicles and total mobility solutions for 4×4, 6×6 and 8×8 military vehicles. Based in France, the company has built its company reputation on the very highest standards of quality and service. It delivers vehicles and equipment that efficiently carry out their public transport, defense, rescue or construction missions every single day, backed up by first-class maintenance and support programs throughout their operational service life.

For more information: www.texelis.com

Focus on Visiativ Solutions

A subsidiary of Visiativ Group with 25 years of customer experience, Visiativ Solutions enables industrial companies to drive innovation, increase efficiency, reduce costs and improve quality through the integration and resourceful use of innovative technology solutions. It delivers tailor-made support to businesses, helping to facilitate their digital transformation and build new experiences for their entire ecosystem.