Sujan Contitech

Find out how Sujan Contitech uses the ‘Bid to Win’ industry solution experience to efficiently manage the entire product lifecycle for their anti-vibration components.

Engineering Bespoke Anti-Vibration Components for Automakers

Built into the chassis of every vehicle on our roads are anti-vibration components: essential parts that we, as drivers or passengers, may never notice, but most likely take for granted. These parts, which are manufactured from advanced anti-vibration materials, include mounts, bushings, dampers and isolators that reduce or absorb vibrations from a vehicle’s engine.

Without advanced anti-vibration components like these, our driving experience would be bumpy and uncomfortable, engines would wear out faster, resulting in greater maintenance costs, and delicate electronics – like engine control units and their related sensors – would be at risk.

India-based Sujan Contitech is a manufacturer and supplier of these anti-vibration components. A joint venture between the Sujan Group and Continental’s Vibration Control division, the company serves automakers the world over.

Today, Sujan Contitech is considered a leader in its field. Its hard-earned success is a result of many years spent building up its digital capabilities. “We have achieved this by leveraging Dassault Systèmes software,” said Hemant Kamble, Sujan Contitech’s general manager for research and development. “Most recently, we have invested in unified modeling and simulation (MODSIM) – an approach that has transformed our end-to-end product development process.”

Managing the Complexity of Creating Bespoke Solutions

Each and every anti-vibration component that Sujan Contitech creates is bespoke. While this is essential to meet the unique needs of automakers, it also creates a high level of product complexity.

“Our solutions are not catalog products,” Kamble said. “We have to define them based on each vehicle category and the requirements we get from various automotive OEMs around the globe. That means customization and – along with the demand for faster time to market – is one of the most important challenges we face today.”

Meeting this challenge is the responsibility of Sujan Contitech’s four R&D teams, who manage projects from the initial request for quote (RFQ), right through to production. These teams not only need to ensure that the products they are engineering can perform under various environmental conditions, but – increasingly – that they are sustainable and made from new and innovative materials.

Sustainability is a major focus across the industry... One way of achieving more sustainable solutions is through lightweighting, since lighter cars consume less fuel and produce less emissions.

The company has been developing lightweight solutions since 2006, starting with polyamide, then polyurethane, and now moving into composite materials. For example, it combines carbon fiber with polyamide to create structural components like engine mounts. These offer the same strength as steel or aluminum, but at a much lower weight.

Prior to implementing Dassault Systèmes’ 3DEXPERIENCE platform, developing products was a complicated business for Sujan Contitech’s teams, not least because design and simulation occurred in succession rather than in parallel. This meant predicting the impact of stress on a metal bracket, for example, or optimizing the stiffness of rubber components to strike the right balance between comfort, vibration control and handling, required multiple iterations between various teams.

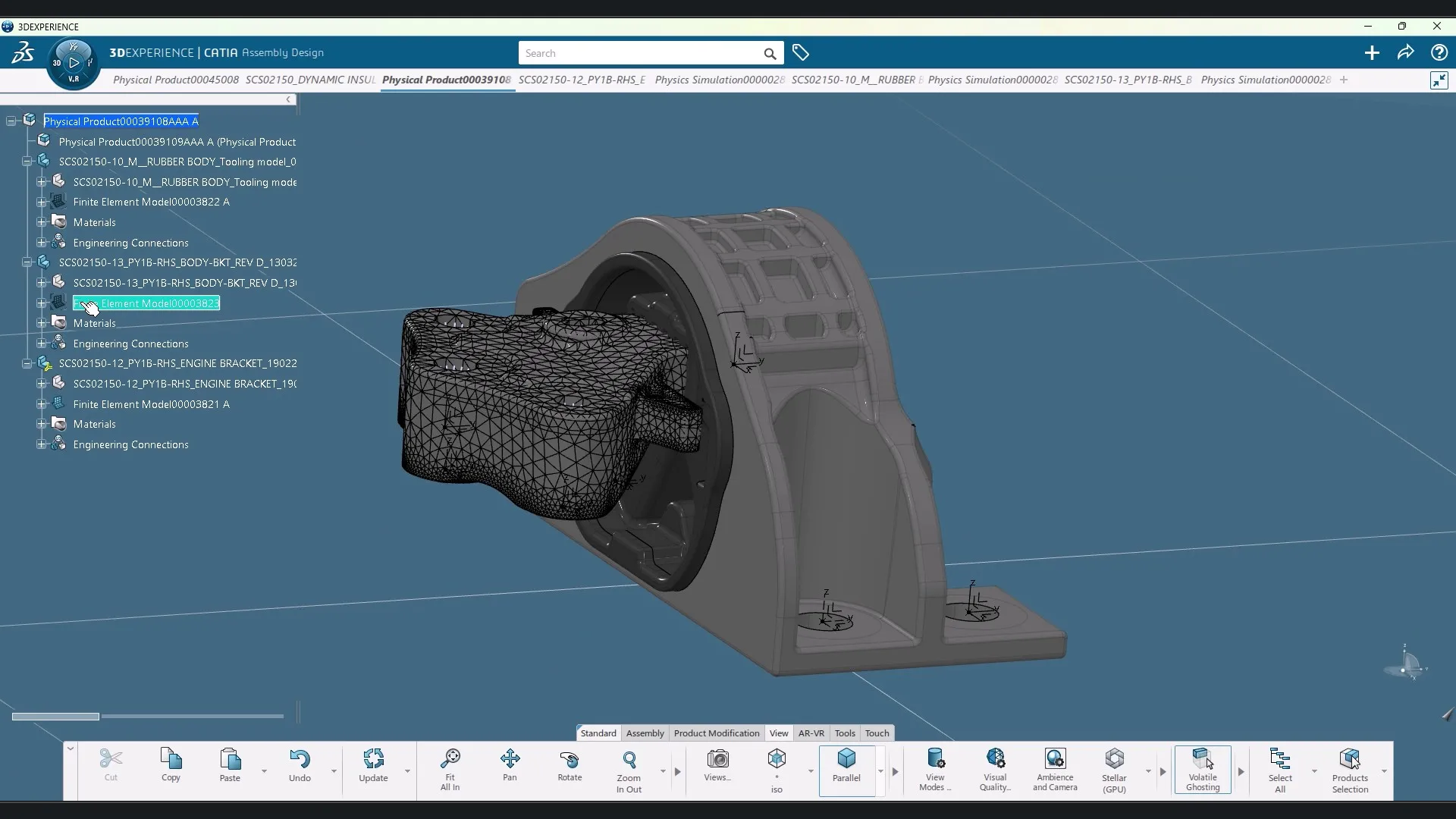

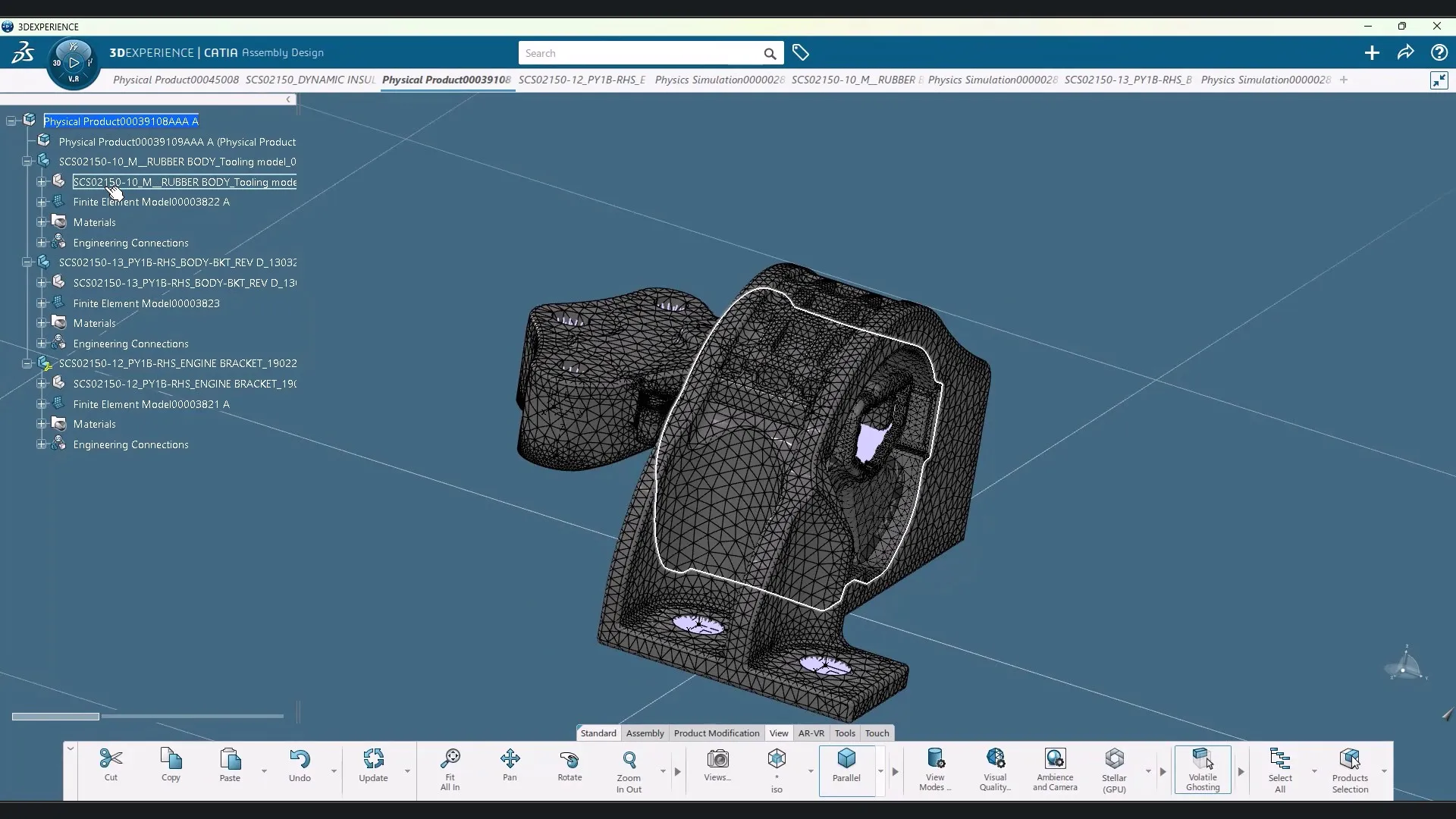

“Rubber is highly nonlinear, so a lot of time was spent optimizing shape, stiffness, load-deflection curves and durability,” Kamble said. “Traditionally, the design team would create the CAD model and then pass it to the engineering team for meshing and nonlinear analysis in SIMULIA, who would then send it back again to the adjust based on the findings during the simulation. This process of iteration would be repeated several times.”

To add to the complexity, collaboration between teams was difficult. Since the communication of design changes was mostly done via e-mails or physical meetings, engineers and managers often worked with outdated information. This led to errors, delays and inconsistencies which meant that product cycles were often unacceptably long.

By implementing the 3DEXPERIENCE platform, this has changed.

Sujan Contitech uses the POWER’BY connector to integrate its existing CATIA V5 data in the platform.

Embracing MODSIM on the 3DEXPERIENCE Platform

Having used CATIA V5 for design since 2018, Sujan Contitech felt that embracing the 3DEXPERIENCE platform, including SIMULIA for simulation and ENOVIA for project and product data management, was a sensible move to help it improve innovation, enhance collaboration and strengthen its position in the market.

The implementation was supported by local Dassault Systèmes business partner EDS Technologies, who took responsibility for process mapping, installation of the platform, training and the delivery of ongoing support. EDS Technologies also installed the POWER’BY connector which, thanks to its multi-CAD support capabilities, helped Sujan Contitech use its existing CATIA V5 data in the platform and enabled it to seamlessly integrate supplier inputs.

The benefits have been immediate. Thanks to its new MODSIM capabilities, Sujan Contitech’s engineers can now validate designs as they create them, cutting out sequential delays and fostering faster iterations.

“Using SIMULIA, designers can now accurately predict the stiffness of rubber components, right within the 3DEXPERIENCE platform,” Kamble said. “This has reduced our design cycles by around 20%, saving us a lot of time lost in iterations.”

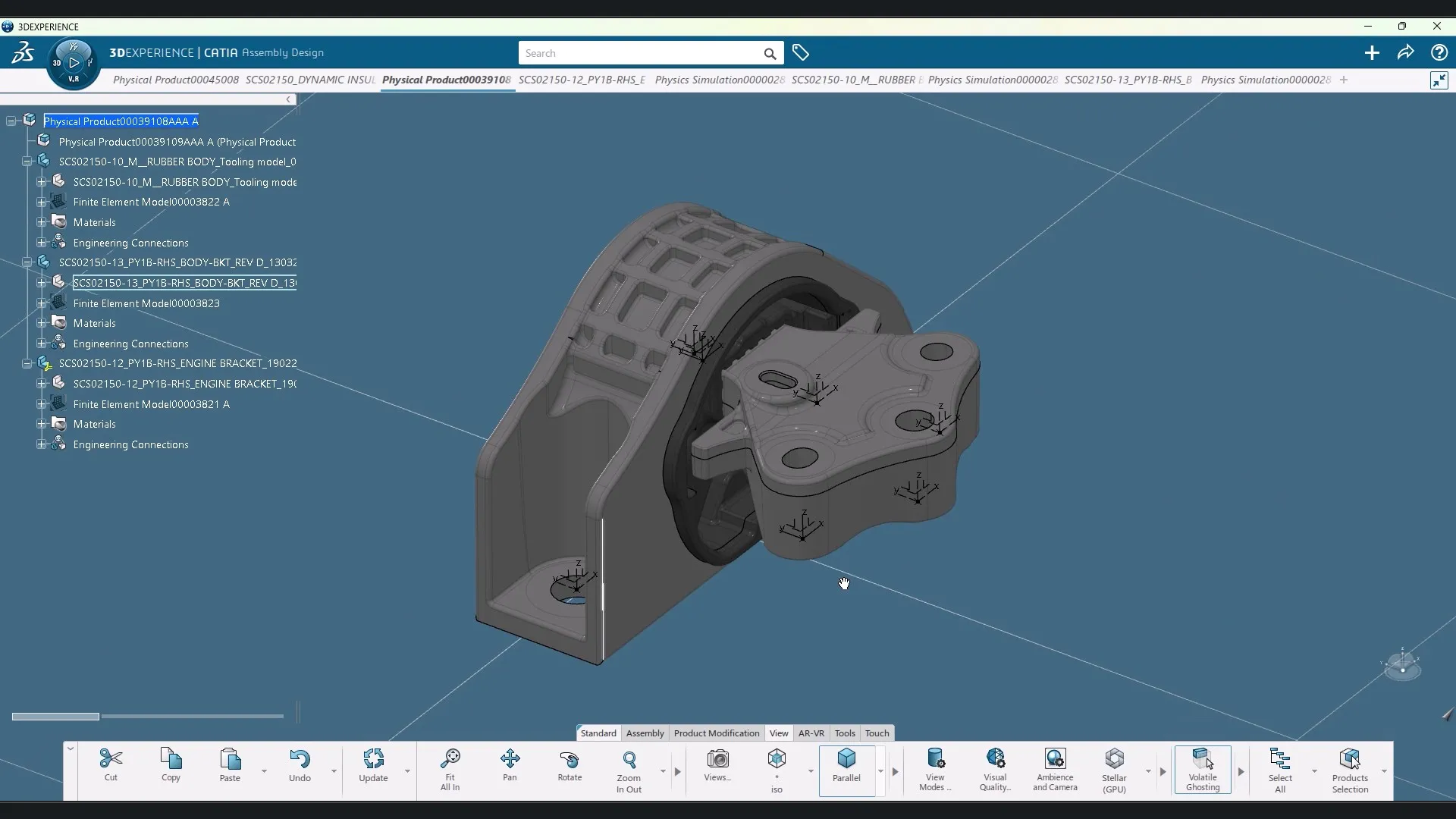

The company has also developed a workflow in the 3DEXPERIENCE platform that allows designers to predict the impact of stress on metal brackets – and this has delivered even more efficiencies, particularly in the development of complex high-pressure die cast (HPDC) solutions. These types of brackets often require the addition of ribs – thin structural reinforcements – which make their geometry more complicated. These features are especially challenging for meshing – the process of breaking down a complex 3D model into smaller elements to prepare it for simulation analysis, and have historically taken engineers a lot of time to prepare.

“With linear calculations in the 3DEXPERIENCE platform, designers can accurately identify the location and level of stress on a bracket, before the final nonlinear analysis in Abaqus,” Kamble said. “This approach has cut lead time by about 40%.”

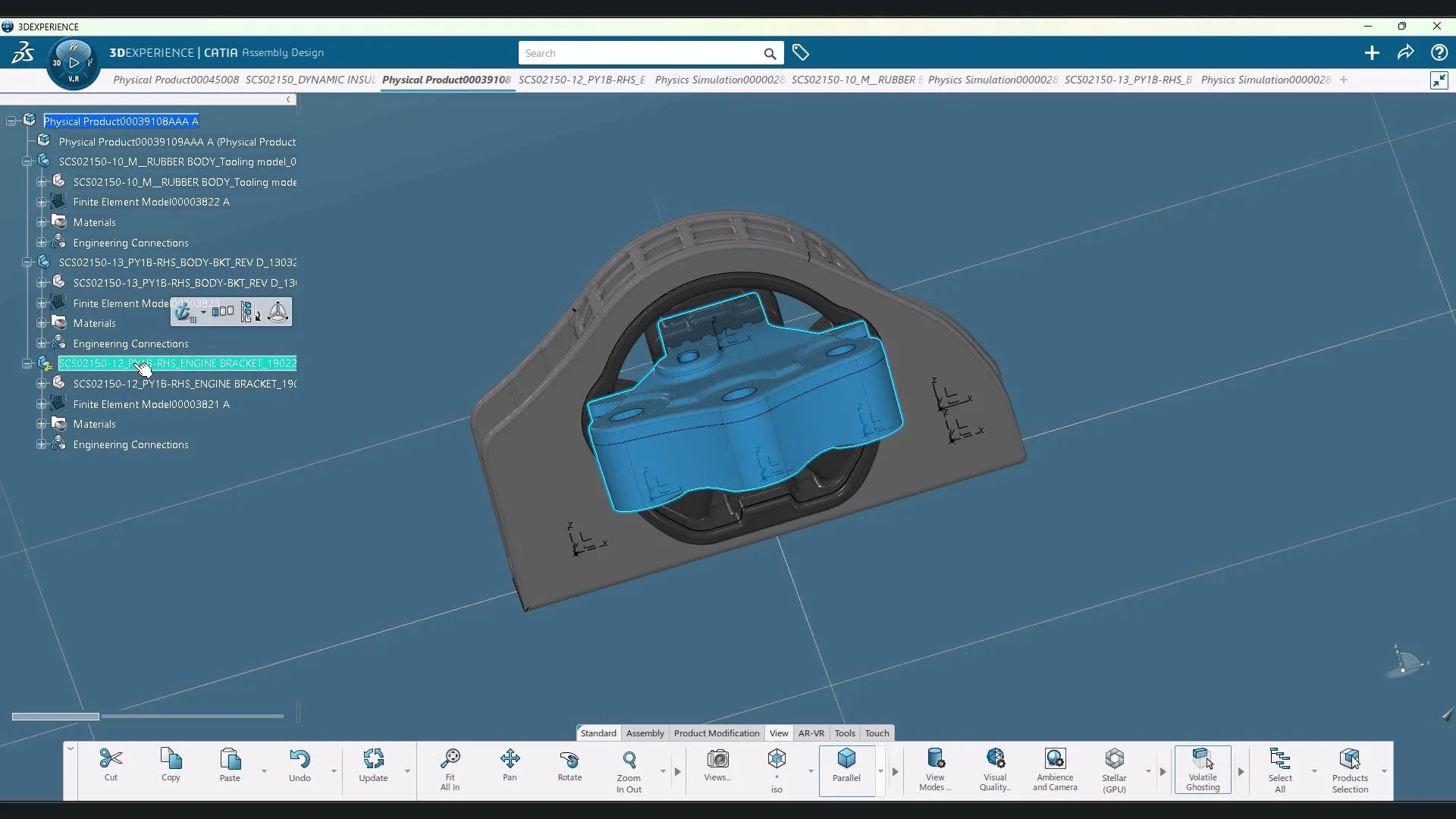

As well as expediting the development of individual components, Sujan Contitech is also using the 3DEXPERIENCE platform to manage complex assemblies for products like engine mounts and suspension bushings which are made up of multiple different materials. “We have to integrate rubber parts with all kinds of materials like sheet metal and plastics,” Kamble said. “With the platform, we are able to manage such assemblies very easily.”

With fewer iterations, Sujan Contitech has drastically reduced design lead time.

A Data-Powered Future

All employees now have real-time access to design data and project status in ENOVIA. This insight has not only prevented costly errors, but expedited decision-making. “We now communicate and share all data via the platform, which has drastically streamlined our workflows,” Kamble said. “Compared to the past, this has reduced the need for non-value-added activities like e-mails and internal coordination by 30%, freeing engineers to focus on more important tasks.”

Sujan Contitech is now actively planning its next step: expanding its use of the platform beyond design data management, to full product lifecycle management.

“We are aiming for end-to-end digital collaboration and data connectivity — from requirements and 3D design to data change management and document management — all within a single solution,” Kamble said. “We are already working with EDS Technologies to define this process. We’ll start with collaborative planning which will enable better resource utilization and more efficient processes. This will further improve coordination across teams, enhance planning accuracy and – ultimately – reduce lead time.”

Overall, the company’s broadened use of the platform will ensure it is in an optimal position to stay ahead of the competition, particularly as new trends in vibration control emerge. “We are already seeing AI and machine learning coming into play,” Kamble said. “For example, enhanced performance through adaptive systems, whereby engines and suspension systems can be tuned automatically and in real-time as a vehicle moves on different road surfaces. This is the kind of future we are moving towards, and we are looking forward to utilizing the 3DEXPERIENCE platform and its MODSIM approach to take these advancements forward.”

Discover more about the Bid to Win industry solution experience.

Focus on Sujan Contitech

designs and manufactures world-class vibration control products and solutions for passenger cars and commercial vehicles. These solutions improve vehicle ride and handling, as well as comfort and safety. The company’s flagship product portfolio includes engine mounts, suspension parts, bushes and dampers. The company is headquartered in Mumbai, has state-of-the-art manufacturing facilities in Chakan, Pune and Chennai and an R&D center at its Chakan facility.

For more information: https://sujancontitech.com/

Focus on EDS Technologies

EDS Technologies, with over 30 years of experience, delivers technology solutions that drive digital transformation across manufacturing, high tech, defense, infrastructure, natural resource, and retail sectors. Headquartered in Bengaluru, India, it is a partner of Dassault Systèmes and the largest PLM solutions provider in India, with a customer base of more than 2,000 customers. It addresses the needs for virtual twins for design and manufacturing, business dashboarding for real-time decision-making, 3D printing for manufacturing, electronic design automation, and IP solutions for chips and SOC designs.

For more information: https://edstechnologies.com/