Shanghai Municipal Engineering Design Institute

SMEDI manages collaborative engineering with Dassault Systèmes’ Civil Infrastructure Engineering industry solution.

Shaping Shanghai's Infrastructure with BIM Technologies

Travelling by road, over bridges and through tunnels is a regular part of our daily lives. But do we ever stop to consider the challenging engineering work that needs to be done to ensure these structures not only function in isolation, but work as a seamless, integrated network?

Shanghai Municipal Engineering Design Institute (SMEDI) thrives on solving complex engineering challenges. Over the last 70 years, the company has completed over 7,000 landmark construction projects in China – including bridges, tunnels and smart wastewater systems.

For example, SMEDI’s engineering expertise was behind the Lupu Bridge, one of the largest steel arch bridges in the world. It also designed the Hongqiao Integrated Transport Hub, which seamlessly integrates Shanghai’s Hongqiao International Airport, high-speed rail (HSR), intercity rail, metro lines, and roads into a single, interconnected transportation system.

“Our long-term vision is to drive the intelligent and sustainable development of urban infrastructure through digital technologies, establishing SMEDI as a global leader in municipal engineering design,” said Junwei Wu, dean of the Digital Institute at SMEDI. “We chose Dassault Systèmes’ 3DEXPERIENCE platform to help us achieve this goal – using the platform as a foundation to create specialized tools in three BIM construction areas: Road Design BIM (RDBIM), Tunnel Design BIM (TDBIM) and Bridge Design BIM (BDBIM).”

Digitizing Municipal Urban Engineering Projects

SMEDI’s partnership with Dassault Systèmes began back in 2012, a time when SMEDI’s projects began growing in complexity.

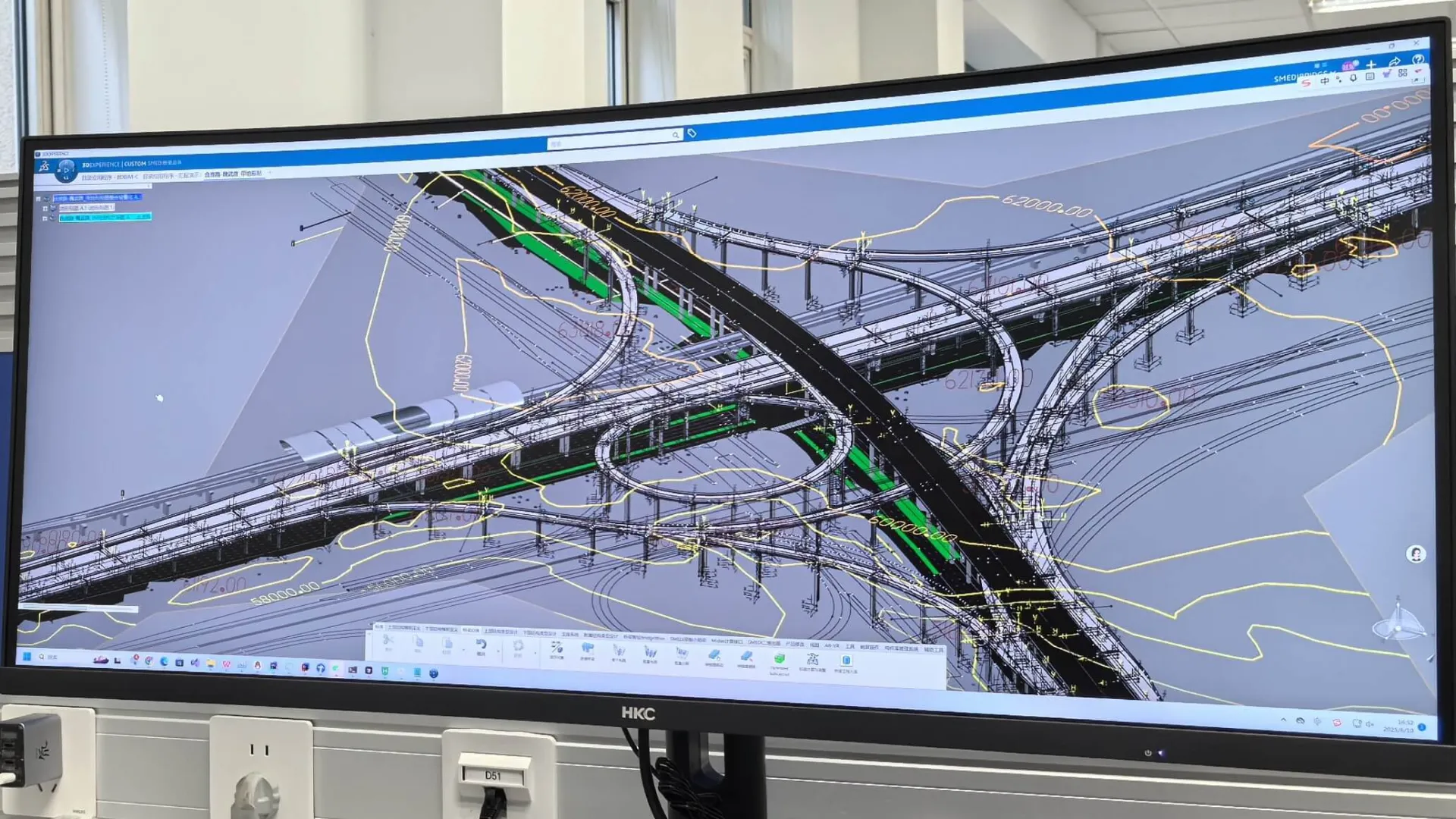

“In our early years, projects focused on single-discipline municipal engineering, like road and bridge design. With urbanization, projects have evolved to be more multi-disciplinary and multi-sector, so we also need to deal with increased sophistication in design, construction and operations,” Wu said. “Coordinating data across multiple disciplines and departments became particularly difficult, especially in large-scale infrastructure projects.”

To better manage these increasingly complicated projects, and to improve the coordination between disciplines, a growing number of municipal clients were mandating building information modeling (BIM) software capabilities. BIM leverages 3D models that represent the physical and functional characteristics of an engineering project. Used as a central and shared knowledge resource, BIM information can inform all aspects of a project lifecycle, including planning, design, construction and maintenance.

The platform unifies design, simulation, manufacturing and operations, supporting digital management of the entire lifecycle. A single source of truth ensures that all team members can access consistent information, minimizing errors and reducing rework.

Creating BIM Tools on the 3DEXPERIENCE platform

Having already formed a strong partnership with Dassault Systèmes, SMEDI was convinced that its collaborative 3DEXPERIENCE platform, which includes CATIA for design and ENOVIA for product data management, could help meet the demands of multi-faceted infrastructure projects.

“To us, the Dassault Systèmes solution suite is the optimal choice for integrating BIM solutions,” said Huan Zheng, chief engineer assistant of the Digital Institute at SMEDI. “The platform unifies design, simulation, manufacturing and operations, supporting digital management of the entire lifecycle. A single source of truth ensures that all team members can access consistent information, minimizing errors and reducing rework.”

With training and support from local partner Shanghai Tecwin Software Technology, SMEDI’s municipal engineers were able to benefit from structured training sessions. This enabled them to quickly master the 3DEXPERIENCE platform’s full range of capabilities so that they could develop its RDBIM, TDBIM and BDBIM solutions.

A Foundation for Greater Project Engineering Success

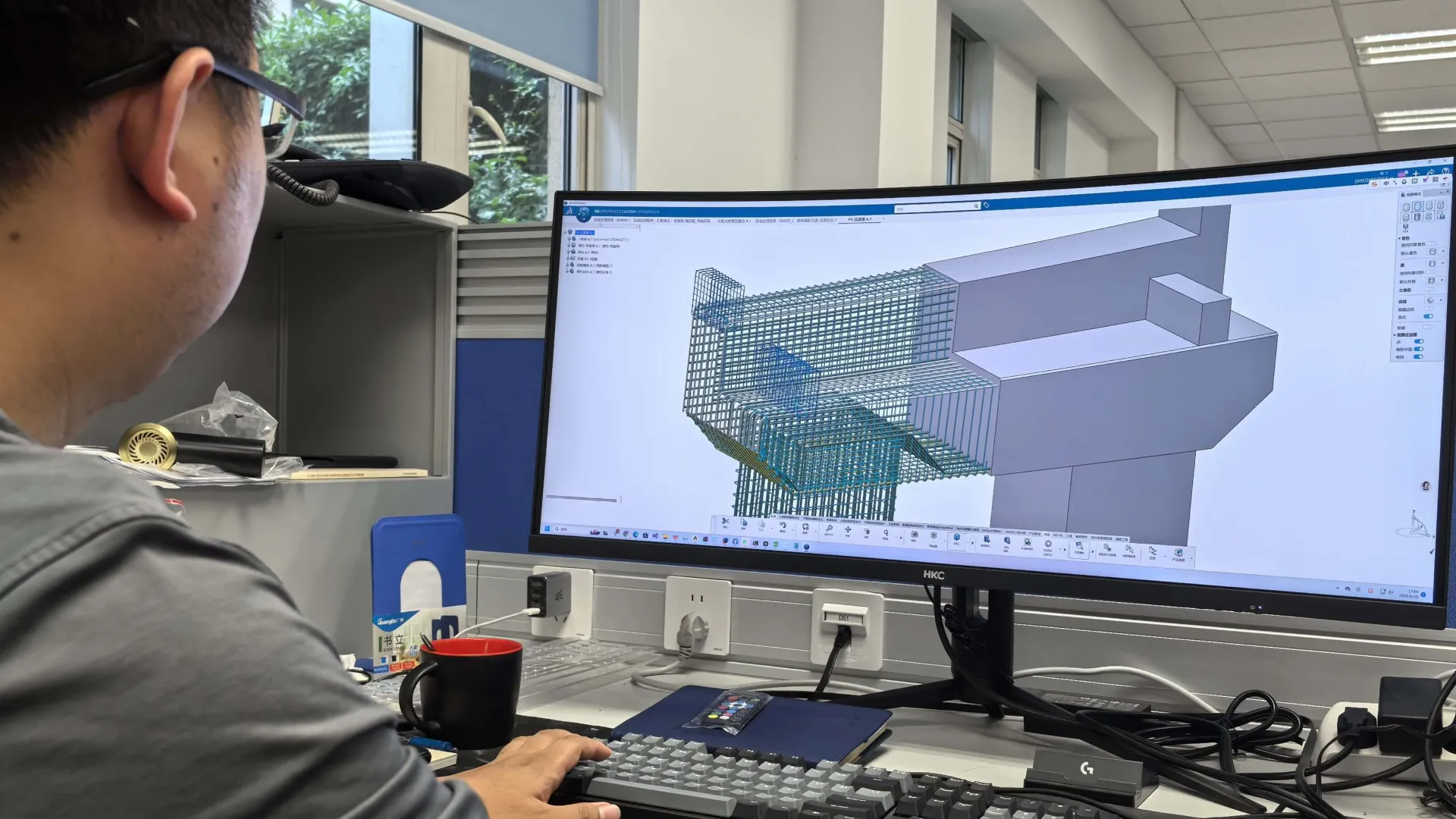

CATIA’s digital modeling capabilities on the platform provide the required design functionality for SMEDI’s BIM solutions, enabling its engineers to create highly accurate 3D models of structures. “The parametric design functionality in CATIA on the platform allows for fast and efficient modifications to meet diverse project requirements,” Zheng said. “This has improved accuracy and reduced design time by approximately 20%.”

For example, in the engineering of the Shenzhen Dawang Bridge – which, at over 232 meters is Shenzhen’s longest single-span bridge – the 3DEXPERIENCE platform played a crucial role in terms of design optimization. The software helped engineers quickly define the shape of the bridge using digital sketch pads to create skeleton lines. Parts, such as beams or columns, were then added from a built-in library, and – because the skeleton lines are parameter-guided – the parts automatically fit to the line. If the line changes, all the connected parts adjust right away, saving time and effort while keeping everything coordinated.

Digital modelling also facilitated clash detection – a process enabling the engineering team to identify and resolve structural engineering conflicts or space violations before any physical work took place, avoiding costly rework during construction. “Parametric design and clash detection helped minimize design errors, accelerate decision-making and improve overall project accuracy,” Wu said. “Because we can quickly identify conflicts, this software has significantly reduced the difficulty of design modifications, which are frequent and even made at the last minute. In the past, the time taken for design modifications sometimes even exceeded the initial design time.”

Thanks to the design precision and construction efficiency afforded by the 3DEXPERIENCE platform, we set multiple records, such as the deepest excavation for a foundation pit.

Seamless Collaboration and Improved Project Transparency

As the platform’s backbone, ENOVIA provides a single source of truth for information such as materials, costs, schedules, key specifications and maintenance needs. Centralized project data management ensures consistency across design, construction and operations phases.

ENOVIA also facilitates real-time collaboration among multiple teams, enhancing communication efficiency and project transparency. “Using ENOVIA, team members can access and update project data in real time, instead of having to go back and forth on email, reducing communication costs,” Zheng said. “The solution also supports global teamwork. For example, project owners, engineers and civil designers from different departments such as structure, bridge and pipeline can coordinate their work in parallel. This seamless collaboration in distributed work environments improve project transparency and we can ensure we meet our high-quality standards and efficiency in every project.”

Meanwhile, SMEDI can use the 3D models to validate different design approaches and identify potential risks before actual construction begins. For example, the Shanghai Airport Link Line was a high-speed rail project that required extensive deep tunnelling. To be executed successfully – and to minimize construction risks – the project demanded precise design capabilities, as well as real-time collaboration.

“SMEDI’s BIM technology was used to design the construction and installation of elaborate underground structures in the Shanghai Airport Link Line project, successfully tackling challenging geological conditions, including soft soil and high-pressure groundwater,” Wu said. “Thanks to the design precision and construction efficiency afforded by the 3DEXPERIENCE platform, we set multiple records, such as the deepest excavation for a foundation pit. We also achieved seamless digital coordination across design, construction and operations, effectively shortening project timelines and reducing costs.”

Plans for the Future

Looking ahead, SMEDI plans to build on its success to date and leverage more capabilities afforded by the 3DEXPERIENCE platform. This will enable it to drive further innovation across the entire project lifecycle.

“We hope to take advantage of Dassault Systèmes’ technologies to not only validate new design methodologies and construction techniques, but to explore new opportunities in smart cities and sustainable infrastructure,” Wu said. “This will allow us to continue to work on increasingly complex municipal engineering projects and further enhance our market competitiveness.”

Discover more about the Civil Infrastructure Engineering industry solution experience.

Focus on Shanghai Municipal Engineering Design Institute

Founded in 1954 and employing over 6,000 people, the Shanghai Municipal Engineering Design Institute (SMEDI) is engaged in the planning, engineering design and consultation, EPC, and the whole process service of project management. The business scope of SMEDI covers various fields of the infrastructure construction industry, including the specialties of water supply, wastewater treatment, road, bridge, hydraulic engineering, rail traffic, maglev, underground space development, and more.

For more information: https://www.smedi.com/en

Focus on Shanghai Tecwin Software Technology

Shanghai Tecwin Software Technology (Tecwin) has 10 offices across China, with an expert consulting team of more than 200 people and nearly 30 years of industry experience. The company is committed to provide advanced digital solutions and enterprise-level application systems for customers in multiple industries including transportation and mobility, industrial equipment, infrastructure, aerospace, hi-tech and life sciences. As an important partner of Dassault Systèmes, Tecwin has more than 1,300 customers with total installed base of 16,000 seats in China.

For more information: https://www.tecwin.com/