NXP

Unlocking the value of continuous forecast improvement with DELMIA Quintiq.

Through its proof-of-concept, DELMIA Quintiq showed great understanding of the complex semiconductor manufacturing environment and demonstrated strong capabilities in improving NXP’s forecasting process.

The challenge

NXP has 20 demand managers. All of them had to work with an overwhelming amount of information and requirements:

- Over 100,000 combinations of customer and product forecasts

- Different forecast output, either in euro or quantity

- Various currencies used in contracts

- Multiple versions of forecasts

- Customer-specific discounts

- Price erosions

Given the complexity, demand managers needed decision support in creating and modifying their forecasts. However, NXP's current planning system couldn’t provide the support they needed. Furthermore, the system was no longer supported by the solution provider. Without the necessary feedback, the demand managers weren’t able to identify which forecast brought the best results and which products they should focus their efforts on. To make matters even more challenging, the consequences of forecast updates were only recalculated and reflected on other forecast levels once a day. This meant that the demand managers couldn't see the effect and respond quickly. Information tracking was another challenge. Because it was scattered across different spreadsheets, the demand managers could not get an overview of the latest forecast. They often couldn’t tell why and when a certain forecast was changed.

Above all, the demand managers didn’t have an effective method to combine forecasts from different sources. They found it difficult to have continuous forecasting improvement because they had no way of knowing which part of the process added value to the forecast. NXP wanted its demand managers to have a single source of truth. They needed a way to see and respond to the business impact of forecast changes. All this had to be supported by an efficient workflow as well as better collaboration process between sales teams, business units and operations teams. Through effective collaborative planning, demand managers could better define quantity requirements and improve revenue planning. The solution should enable the demand managers to gather as much input as possible from sales and statistics for optimal forecasting results.

The search

NXP sought a single platform for accurate demand planning. It needed a solution that would improve the forecasting process, establish forecast accuracy, boost sales collaboration and provide better visibility. The solution should also address NXP's planning gaps in terms of data and workflow by providing:

- Seamless integration of data sources

- Immediate feedback on impact of forecast changes

- Continuous improvement of the forecasting process

The choice and implementation

As NXP’s ideal solution provider, DELMIA Quintiq ticked all the boxes. DELMIA Quintiq Demand Planner was configured for effective demand planning on a single integrated planning platform. Through statistical analysis of historical data or collaborative input, the solution enabled the creation of high-quality demand forecasts. These accurate forecasts will help NXP better anticipate customer demand and lower safety stock levels.

“Through its proof-of-concept, DELMIA Quintiq showed great understanding of the complex semiconductor manufacturing environment and demonstrated strong capabilities in improving NXP’s forecasting process,” said Jan Paul Smits, solution manager at NXP. He added, “We chose DELMIA Quintiq for its demand planning capability. DELMIA Quintiq was also quick to respond to our feedback on areas to improve and we're impressed with the way the DELMIA Quintiq team worked – they showed a lot of focus and drive.” The DELMIA Quintiq solution was designed and tested in 2014 at NXP’s headquarters in Eindhoven, the Netherlands, before it was rolled out globally in three phases in 2015. The DELMIA Quintiq and NXP teams worked closely every step of the way to ensure a smooth deployment.

The result

“We're happy with the outcome of the implementation,” said Evelien Klein, director of demand management at NXP. “The DELMIA Quintiq solution doesn’t merely support our forecasting process, it enables continuous forecast improvement. As our demand managers are no longer limited by the planning software, they can now focus on generating better forecasts.” NXP is now better prepared to face the upturns and downturns of the semiconductor cycle, making the right decisions at the right time to seize opportunities for higher profitability. DELMIA Quintiq helps NXP reduce inefficient data-gathering efforts as well as improve workflow management – from sales input to final consensus forecasting. The planning solution centralizes all of NXP’s data that’s relevant to forecasting. This offers greater visibility into the data and forecast, along with solid support for future sales predictions.

By using a segmentation approach where products are categorized based on forecast volatility, sales volume and product status, the system is able to determine the best and most accurate forecast signal. NXP account managers can now focus on forecasting products that need the most attention. The DELMIA Quintiq solution also allows demand managers to save time by comparing forecasts on a single screen. The updating of information has been made much easier. “Our demand managers tell me how happy they are with the flexible navigation provided by the DELMIA Quintiq solution. It allows them to analyze the forecast signal on any level they like. With DELMIA Quintiq, we can now rely on a single source of truth,” said Evelien.

She added, “Our integration with other tools has improved greatly. We can now easily pick data from any other system, upload it into DELMIA Quintiq and compare the information from various input sources. Interfacing with other applications has improved with DELMIA Quintiq. We're very satisfied with the outcome as we have improved our integration capabilities.” Jan Paul was happy to share his feedback too: “The DELMIA Quintiq solution has vastly improved our IT management process. I’m pleased to see that knowledge transfer to our IT partners is now simpler and hassle-free.”

With the DELMIA Quintiq solution, NXP is now better equipped to deliver higher quality forecasts and thus, improve customer satisfaction and cost-efficiency.

NXP Fast Facts

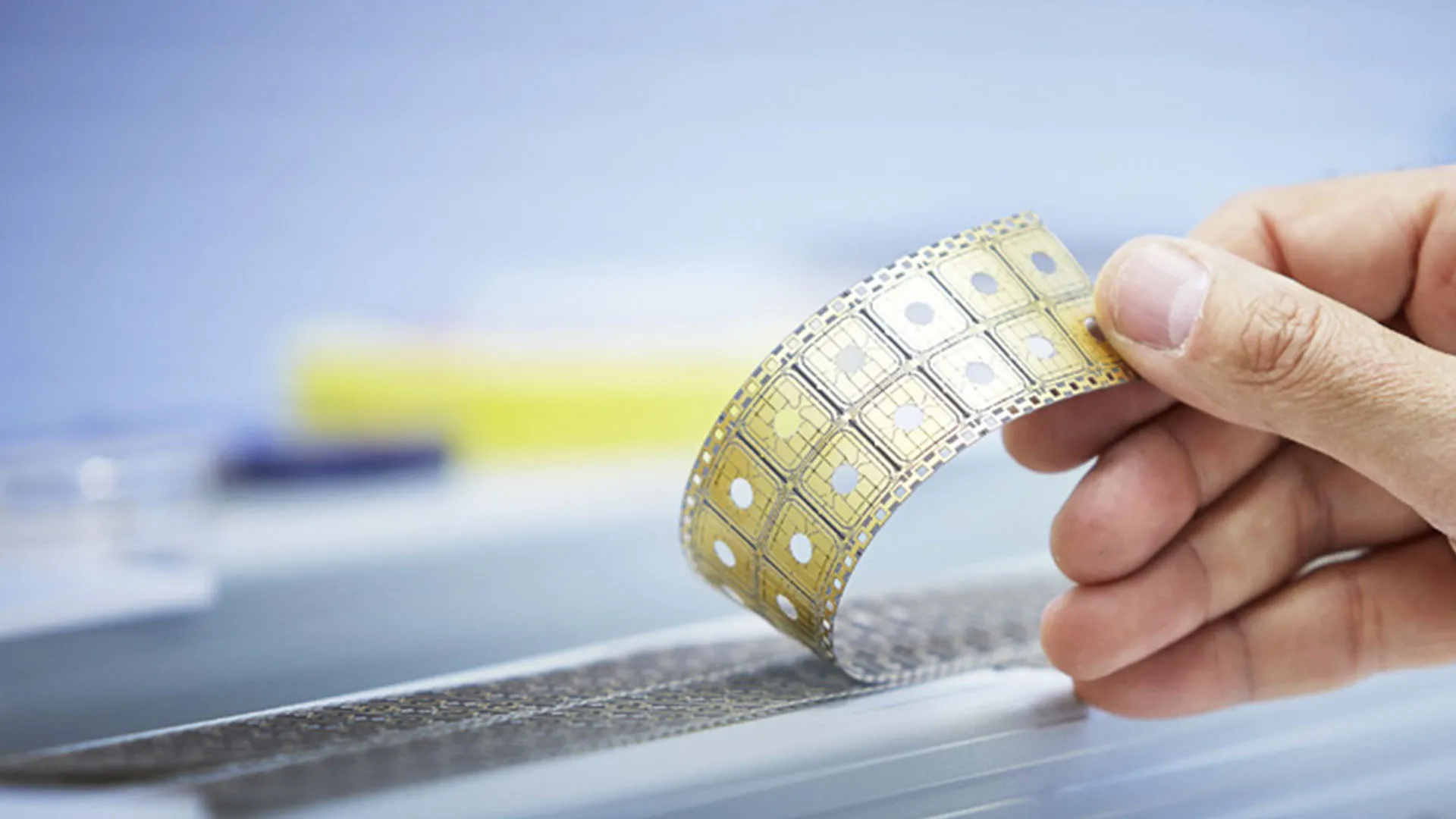

Business: Semiconductor manufacturing

Headquarters: Eindhoven, the Netherlands

Presence: More than 130 facilities in over 35 countries

Size: 45,000 employees (after Freescale merger)

Quarterly revenue: USD 2.2 billion (Q1 2016)