NExT

Italian startup NExT is engineering electric modular vehicles that can be docked with each other to create extra capacity. It adopted Dassault Systèmes' cloud-based solutions to make the design processes faster and more efficient. The Global Modular Architecture industry solution experience enables the design in the context of the entire vehicle and improves collaboration.

The path towards smart urban mobility

The current model of public transport service delivery is fundamentally broken. That’s the view of Tommaso Gecchelin, founder and chief technology officer at NExT, an Italian startup developing an advanced intelligent transport system based on swarms of modular electric vehicles.

“We often see buses running totally empty,” Gecchelin said in a press release. “It’s a normal scenario in every big city because public transportation vehicles are sized based on the maximum capacity but are unable to adapt to varying demand throughout the day.”

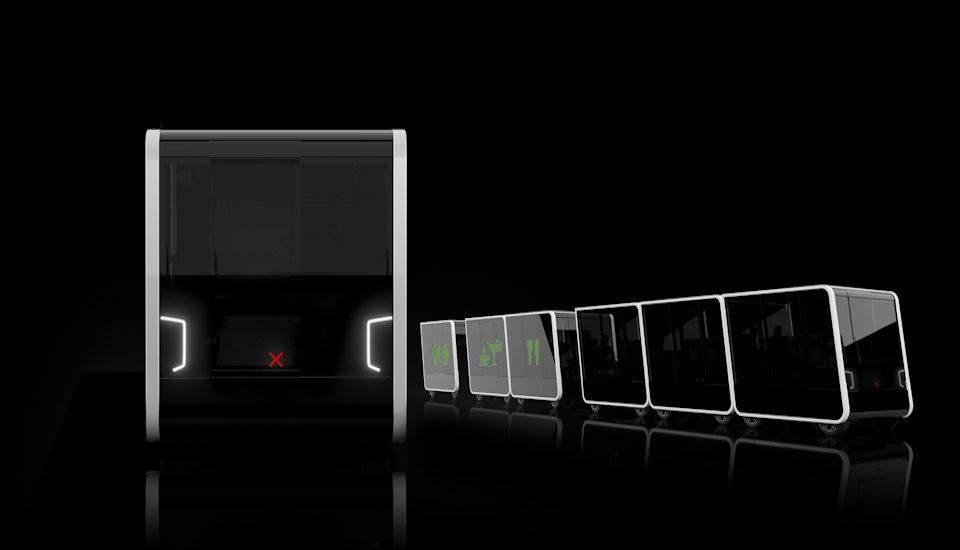

NExT’s vehicles solve this problem. During peak hours, they can start their journey with five or more pods that dynamically connect using a robotic system to create a single vehicle with no articulation. Depending on the number of pods, NExT’s capacity can match an 18-meter bus or even a tram. During low-traffic hours, NExT can run in a lighter configuration with one, two or three pods, keeping the others parked and charging ahead of the next peak period.

NExT’s zero-emission vehicles are a sustainable smart urban mobility solution: They use up to 60% less electricity than standard electric buses because they run only with the minimum necessary number of pods to accommodate demand. “The operational pods use much less energy, not only due to being lighter but also because the space occupied by passengers that needs to be cooled or warmed depending on the season is only a fraction of a traditional fixed capacity bus,” Gecchelin said in a press release. “Moreover, the possibility of reducing the length and volume of the bus allows for a general reduction of road traffic.”

NExT requires industry leading tools to design, test and optimize a bus that is expected to transform urban mobility. That’s why it is taking advantage of Dassault Systèmes’ 3DEXPERIENCE for startups offer, which provides it with a best-of-breed portfolio of solutions, including CATIA for design.

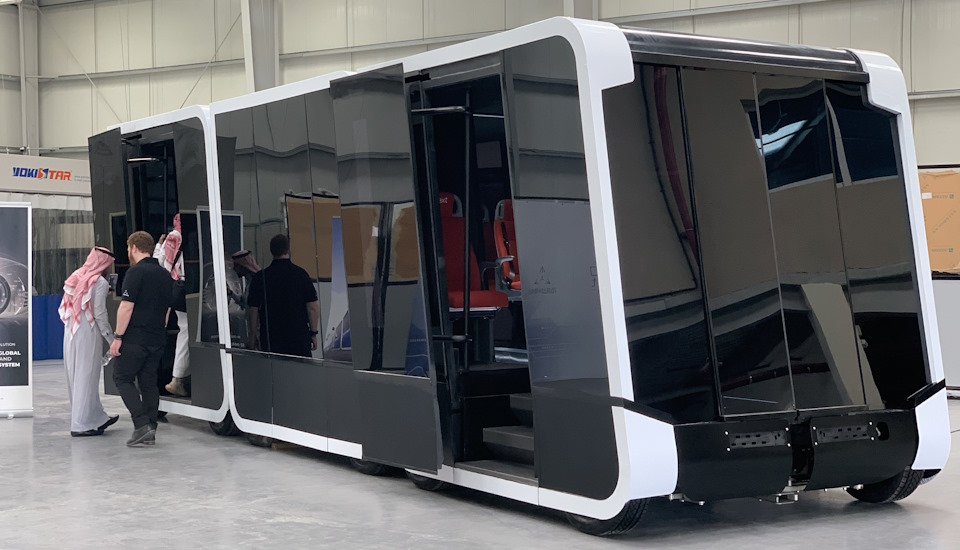

Nine prototype vehicles are currently being tested in Dubai and in the company’s hometown of Padua.

The need for speed

NExT’s team hasn’t always used Dassault Systèmes solutions. In the early days of the company’s formation, it used an alternative CAD solution which presented several challenges.

“Our modular urban mobility solutions contain a huge amount of assembly data, and our previous solution wasn’t able to handle this,” said Edoardo Fantin, NExT’s chief engineer. “Instead, we had to open sub-assemblies, but this was a problem because we couldn’t work in the context of the entire vehicle.”

This wasn’t the only issue making the design process slow and cumbersome. “We had to always design new components from scratch,” Fantin said. “And modifying existing part designs was time-consuming. We needed a better solution.”

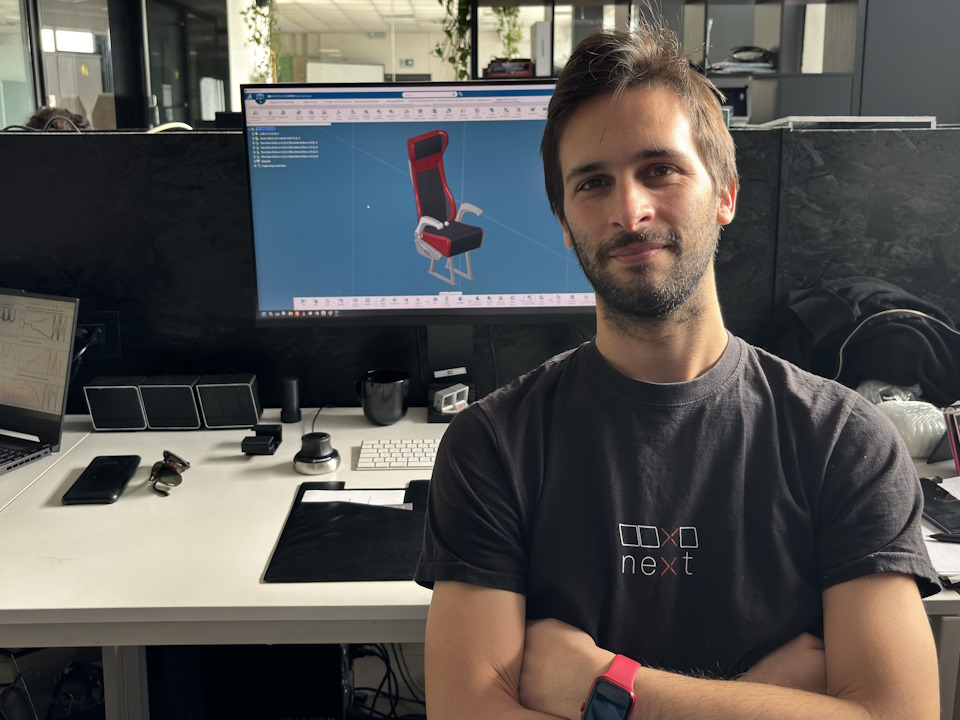

Having witnessed Fantin’s issues, a colleague suggested that Dassault Systèmes design solutions might be a better fit. Fantin initially adopted the Dassault Systèmes SOLIDWORKS app, before opting for the 3DEXPERIENCE for startups offer, enabling SOLIDWORKS and CATIA to be used in parallel.

“We chose the cloud-based versions of the Dassault Systèmes solutions, which meant we could not only implement the solution almost instantly, but also benefit from the ability to securely work from anywhere with an internet connection,” Fantin said. “We also liked the fact that the cloud-based solution can scale as we grow, and ensures we always are working with the most up-to-date tools on the market.”

With help from his colleague, Fantin was up and running incredibly quickly. “I was using CATIA straight away,” he said. “The solution is very intuitive, so I didn’t need much training – I picked it up quite quickly with support from my colleague. I’ve also received a lot of help from the Dassault Systèmes IFWE Community, which gives me direct access to the support team who can help me with advice on industry best practice. This is a really great feature and not something I’ve seen available in other design tools.”

My colleagues can see any changes I make to a design in real-time. I don’t have to e-mail them to tell them I’ve made an update. Additionally, because everything is stored logically in the cloud, we are confident we are always working on the most up-to-date file.

Working faster and smarter

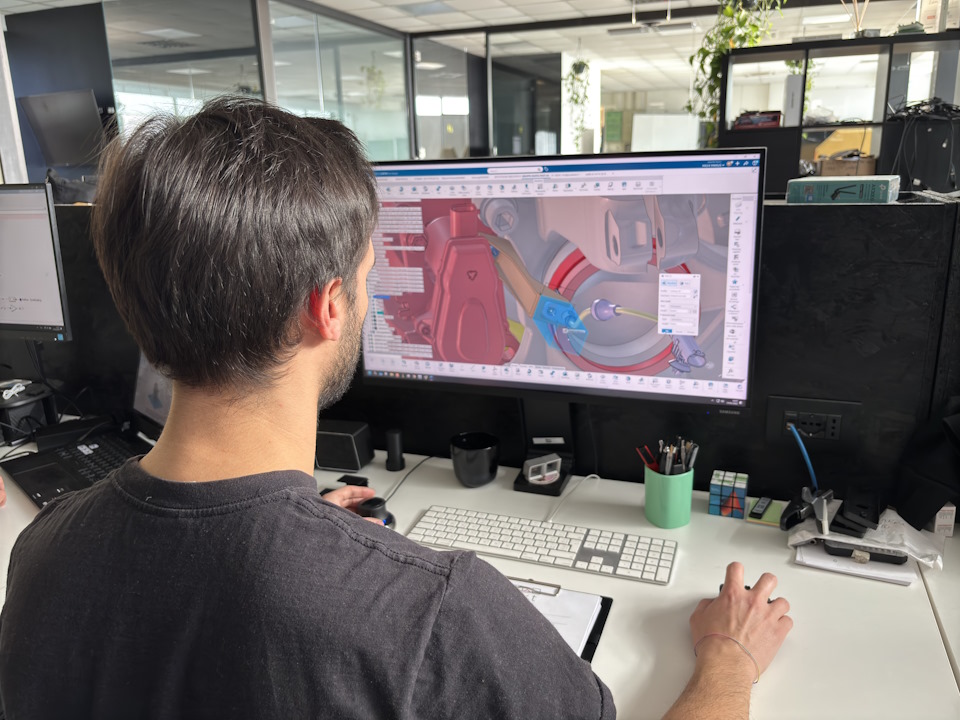

CATIA’s various apps – including Part Design, Sheet Metal Design and Assembly Design – enable Fantin to engineer all elements of the NExT smart mobility vehicle – including the engineering parts, the cabin interior and the overall structure – much faster than previously, all in a single environment.

“I can now open the entire assembly of the vehicle with ease and design a specific part – such as the driver’s seat, a new kind of floor system or even the air conditioning tubes – far more precisely because I can see the part in the context of the entire vehicle,” Fantin said.

This makes the innovation process simpler. “We can brainstorm a new idea much quicker than previously,” Fantin said. “With one click of the mouse, we can move very big parts inside the assembly and discover a new way to fit a part into the vehicle, for example.”

Thanks to CATIA’s PartSupply components library – a comprehensive catalog of 3D components sourced from thousands of suppliers – Fantin no longer has to design various items from scratch. “In our vehicle, there are a lot of screws, a lot of nuts and a lot of fasteners, for example,” he said. “Instead of taking five minutes to design each of these items, I can simply download them from PartSupply and insert them directly into the assembly. This saves a huge amount of time and therefore money.”

CATIA’s parametric capabilities also mean that once parts unique to NExT are designed, they can be reused. “It’s so easy to modify parts in CATIA,” Fantin said. “You can change just one number, and the part that you have designed will change completely. I can adjust the sizing of the driver or passenger seats, for example, to optimize the use of space, but without impacting the integrity of the design.”

Thanks to the 3DEXPERIENCE platform, engineers can now easily open up entire vehicle assemblies and design certain parts - such as the driver's seat, a new type of floor system or even the air conditioning pipes - much more precisely.

Cloud-based collaboration

With all team members now working within the same cloud-based system, access to information has improved and collaboration is easier.

“My colleagues can see any changes I make to a design in real-time. I don’t have to e-mail them to tell them I’ve made an update,” Fantin said. “Additionally, because everything is stored logically in the cloud, we are confident we are always working on the most up-to-date file. Unlike when you work in a file-based system, it’s not possible to accidentally open a previous iteration of a design. This minimizes the likelihood of mistakes.”

CATIA’s multi-CAD environment also makes collaboration with different suppliers straightforward. “We have many suppliers,” Fantin said. “CATIA makes it easy to save files in STEP format, so we can exchange design files quickly and easily.”

As we look to transform the future of transport service delivery, we are looking forward to pushing the boundaries of innovation and maximizing the power of Dassault Systèmes solutions.

Expanding smart cities and infrastructure with new capabilities

NExT has made significant developments with its smart mobility solutions. It has now designed and manufactured nine prototype vehicles, which are currently being tested in Dubai and in the company’s hometown of Padua. Mass production is expected to begin in 2025, with an initial 30 vehicles rolled out in the first year, and a further 100 vehicles hitting the streets in 2026.

Getting the vehicles finalized and ready for engineering will require NExT’s team to explore more of what the Dassault Systèmes platform has to offer. “As we look to design the electrical components of the vehicles, we are keen to leverage new functions such as the Wire Harness Design and Electrical Routing features in SOLIDWORKS,” Fantin said.

This is just the beginning of the journey for this smart urban mobility project. While NExT’s CEO expects the first rollout of buses to be used in a simple and easily implemented initiative such as the ‘variable capacity bus’ scenario, he believes future applications will include an advanced on-demand shared taxi system.

“Dubai is the perfect city to use NExT in a taxi-like configuration,” Gecchelin said in a press release. “It is made up of some very dense and crowded points of interest spread over a rather large territory dotted with thousands of hotels and private residences. As such, NExT will allow citizens to summon a vehicle at their location and set their destination. On the way, the modular vehicle will be able to dock others that are going to the same place. Once passengers have moved within NExT’s modules headed to the same place, those left free will be able to detach to meet other customers in a system that allows door-to-door dynamics."

NExT could also be used in countless other applications, including retail and on-the-move services, healthcare, security, cargo transport and airport services. Once infrastructure allows, the transport solutions will be able to operate completely autonomously.

Advanced simulation capabilities in the Dassault Systèmes portfolio will help NExT explore these new applications of its vehicles. “We’re interested to see how we could use SIMULIA to simulate how our vehicles might interact with the environment in new and exciting scenarios,” Gecchelin said. “As we look to transform the future of transport service delivery, we are looking forward to pushing the boundaries of innovation and maximizing the power of Dassault Systèmes solutions.”

Discover more about the Global Modular Architecture industry solution experience.

Focus on NExT

Italian startup company NExT wants to revolutionize urban mobility systems with its sustainable, modular and electric transportation solution. Each NExT module can join and detach with other modules on standard city roads. When joined, they create an open, bus-like area among modules, allowing passengers to stand and walk from one module to another.

For more information: https://www.next-future-mobility.com/