MTorres

MTorres chose the 3DEXPERIENCE platform and ENOVIA to replace its existing Product Data Management solution, SmarTeam, and power its product development process in a collaborative environment.

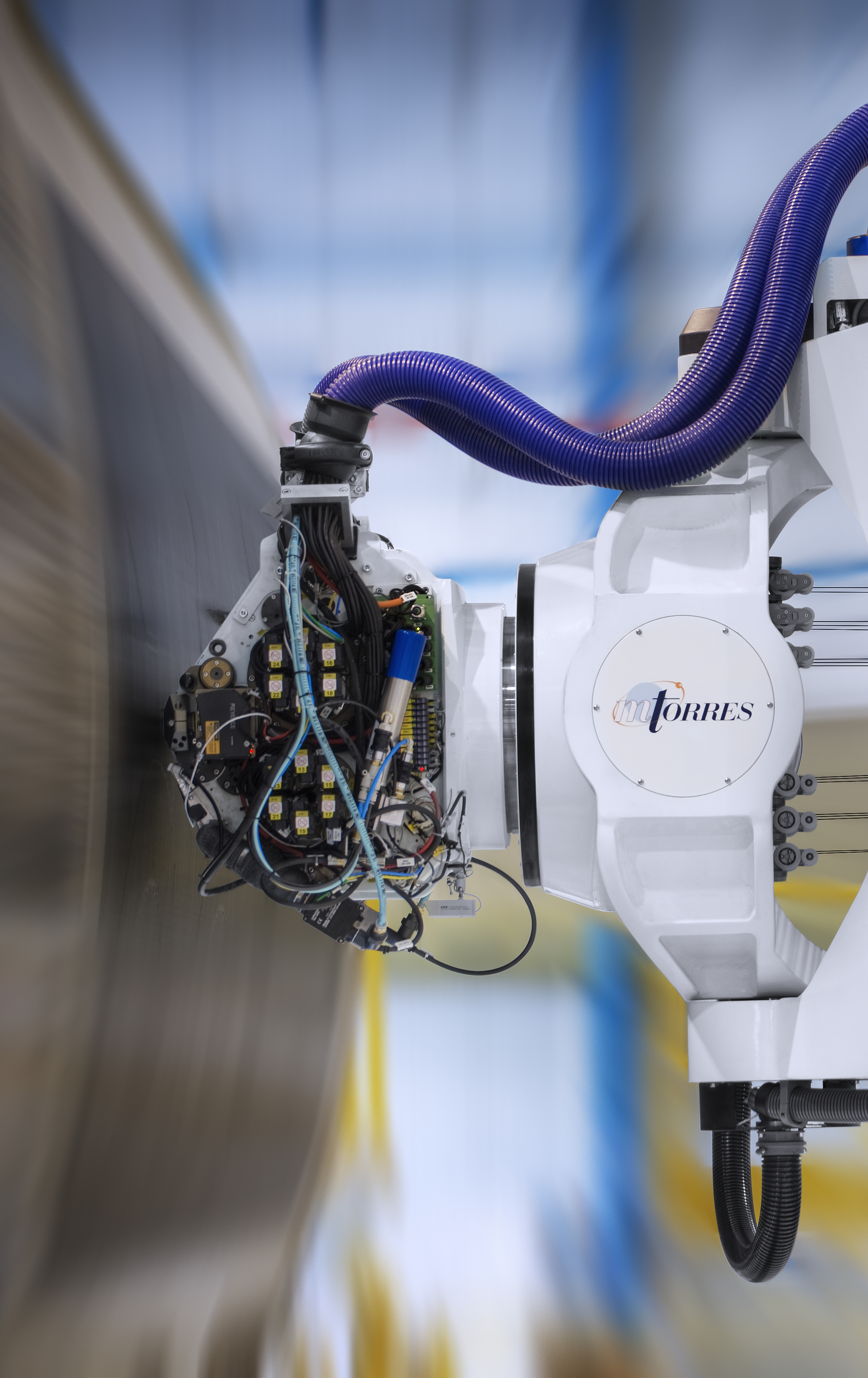

Innovating complex industrial processes

Since its founding by its namesake, Manuel Torres, in 1975, Spain’s MTorres has been providing its customers with innovative solutions for the automation of highly complex industrial processes in the paper converting and aeronautics sectors. Headquartered in Navarre, Spain, MTorres’ goal has been to help its worldwide clients solve specific and concrete problems in the automation of manufacturing processes while enabling them to improve productivity and efficiency.

“Innovation is very important for MTorres,” says Luis Saez, Chief Information Officer, MTorres. “Our company was designed and developed as an industrial group, qualified in advanced technology to develop highly complex, innovative solutions in industrial process automation. Our desire is to provide our customers with new solutions that improve productivity and efficiency.”

The company’s vision is to build strong and trusted customer relationships that allow MTorres to become an extension of its clients’ organizations. One way the company is working to ensure its success is with a commitment to replacing its legacy technology solutions with more modern, integrated platforms.

Innovating not just machines, but processes

In the 1990s, MTorres diversified beyond its paper converting sector business into aeronautics, working with industry leaders such as Boeing, Airbus and Embraer. It specializes in comprehensive solutions for carbon fiber manufacturing, metal components and automated assembly. In recent years, aeronautics represents approximately 75% of MTorres’ business.

The company not only works closely with its aeronautics customers to provide highly innovative production equipment and automation solutions, but also to help clients develop and optimize new production processes. In particular, as companies struggle to allocate resources and complete projects amidst the COVID pandemic, they look to strategic partners like MTorres.

“Instead of providing a collection of standard equipment, we work with our customers to adapt our machines to their needs and processes,” Jesús Cobos, IT PMO and Applications Manager at MTorres, explains. “That means no single machine is the same as another – and although that can be challenging, it’s one of the main reasons our customers choose to work with us. They know we are very invested in the research and development that goes into our machines and that we provide the latest technologies, but it goes beyond providing an isolated machine. Today, our customers are looking for the whole process.”

Because its aeronautics clients’ programs and projects are growing rapidly in both size and complexity, MTorres must provide an orchestrated series of machines and processes to produce, for example, the entire wing of an airplane, and the services to support that specific process. Often, this means MTorres’ teams are embedded at the customer’s facilities, collaborating in lockstep with its clients.

“We work on projects very closely together with our customers,” says Javier Galarregui, 3DEXPERIENCE Officer in the Mechanical Engineering department at MTorres. “When they have really specific challenges and want to develop a new process or improve an old one, they call on us to custom-tailor new technology with them that is specifically designed to this new need.”

Modern and secure

As its business and the number of projects with clients has grown, it has become imperative for MTorres to upgrade its technology solutions to remain agile and competitive.

Because of its direct partnership with OEMs, MTorres must work with the CAD tools used by those key clients. Therefore, its aeronautics engineers work in a variety of different releases of CATIA V5, and are moving into use of 3DEXPERIENCE CATIA.

To manage all of its aeronautics product data, MTorres had relied on SmarTeam since 2005. As that system aged, however, data created in the newer CATIA V5 releases could not be stored in the system.

“With SmarTeam, we had a lot of data outside the system because it couldn’t be uploaded, so we stored this data in server folders,” Cobos explains. “SmarTeam was getting old and out of support. But we waited a long time to upgrade because we had a lot of legacy data, and we needed it for current and future projects. It was a really difficult decision to make, but we knew we had to move to a more modern system.”

With more than 70 simultaneous projects in work in recent years, MTorres knew it needed a system that could grow with its business, manage all of its product data and extend access to key stakeholders outside its engineering teams.

After a comprehensive benchmarking study, MTorres chose to continue its alliance with Dassault Systèmes and selected the 3DEXPERIENCE platform and ENOVIA to connect its users around a single, up-to-date product definition.

The benefits that convinced MTorres that the 3DEXPERIENCE platform was the right choice included its collaborative innovation environment, visualization tools, the ability to unify and leverage its existing CAD data, and the capability to work in standard processes.

Migrating all of the company’s product data proved the biggest challenge, but with the help of its longtime Dassault Systèmes business partner, ABGAM, the production environment rolled out to users in June 2019.

“ABGAM worked with us on the infrastructure installation, the customizations, the training and the project management in close conjunction with our teams,” Cobos says. “They prepared a migration tool to help us with the data migration, and we continue to work closely together for system support.”

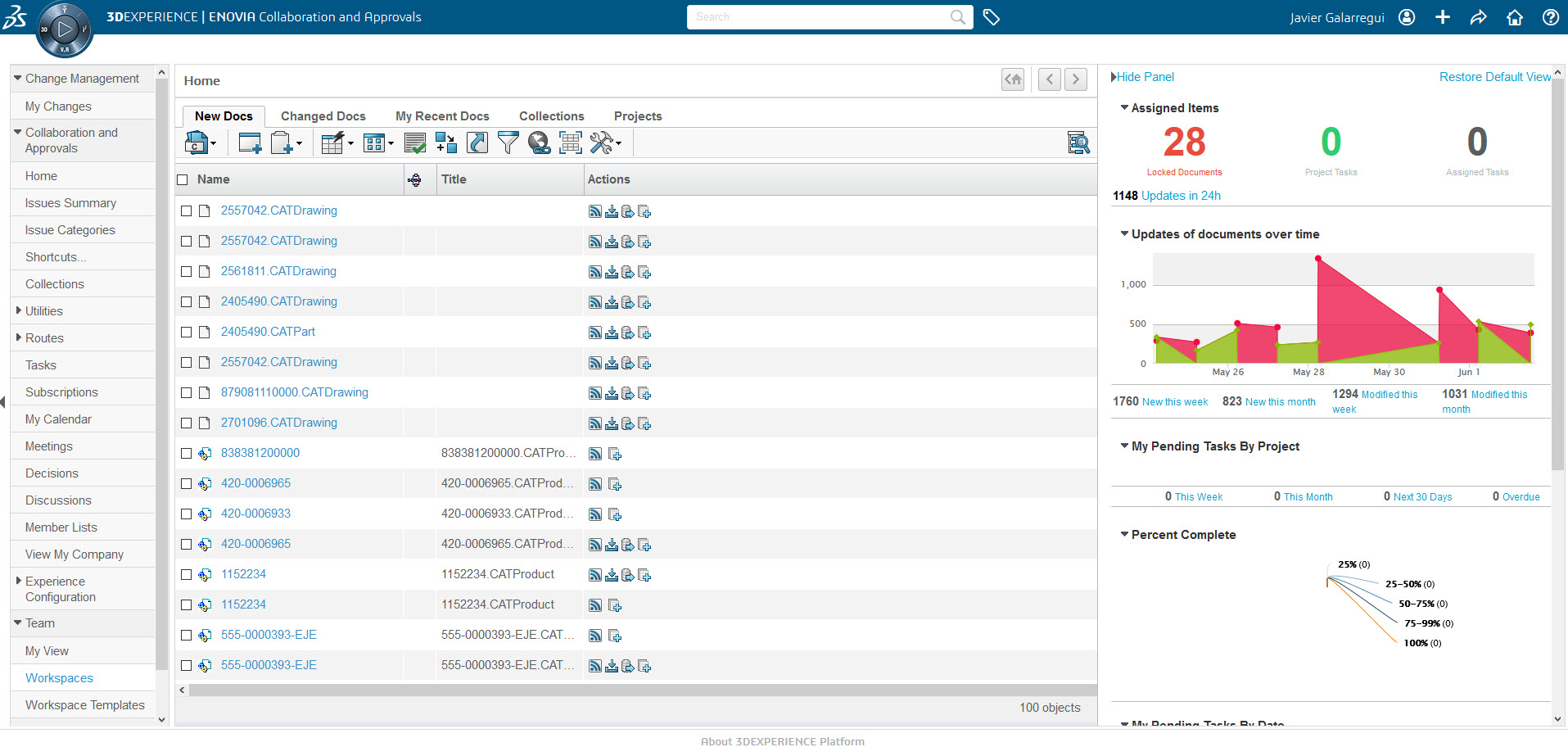

Now, all of MTorres’ more than 250,000 aeronautic product data files for new projects are in the platform and easily accessible to its more than 75 engineers as well as 30 additional 3DEXPERIENCE platform users in the company’s purchasing and production teams, enabling them to all work together on a common product definition.

Intuitive Environment

As with the introduction of any new software tools, change management among users is always one of the biggest challenges, but Galarregui says learning to use the 3DEXPERIENCE platform took just a few days. “It’s a very intuitive environment with the 3D Compass at the center. I worked with SmarTeam for many years, but now I really like the CATIA V5 integration with the platform. It’s really useful and fast. When we tested it in contrast with the SmarTeam integration, it’s one of the things I liked most.”

One of Galarregui’s favorite apps is ENOVIA Design Review Manager. “Visualizing and navigating in 3D models that I’m reviewing is easy,” he explains. “And then I can do the markups and share them with the designers.”

Another key app for MTorres’ designers is ENOVIA X-CAD Designer. “We use it to save information about our CATIA models and for operations like lifecycle change and design copy,” Galarregui says. “The X-CAD Designer navigation is very, very useful.”

It’s a very intuitive environment with the 3D Compass at the center. I worked with SmarTeam for many years, but now I really like the CATIA V5 integration with the platform. It’s really useful and fast.

Since MTorres adopted the 3DEXPERIENCE platform, Galarregui says improvements in the time to load, save and download designs as well as the capability to “design right the first time” are leading to shorter overall design times. “New functionalities, like rename and duplicate, are very good – and they save a lot of time in design,” he explains.

Another key benefit for the company’s teams is the platform’s collaborative innovation tools. “3DEXPERIENCE has a lot of applications for collaboration, like 3DSpace, 3DDashboards and messaging,” Galarregui says. “They help a lot in teamwork. We use 3DSpace daily for sharing and organizing CATIA models. And 3DPlay is a very useful application so that other departments that don’t use CATIA can see and navigate CATIA models.”

Cobos agrees. Although MTorres’ main users are its designers and engineers, stakeholders from purchasing and production also must review designs.

“For our engineering team that was working with SmarTeam, the benefits are truly significant, but not as great as for those in other departments who had no system in the past,” Cobos points out. “They had no PDM or any solution to manage CAD data, so this will be a tremendous benefit to those teams.”

Standard processes OOTB

“3DEXPERIENCE is a more collaborative, more stable, more secure solution,” Cobos says. “In our SmarTeam system, we defined a lot of customizations to try to facilitate our work. With 3DEXPERIENCE, we’re trying to work with the standard processes and just do a few customizations. From an IT point of view, it’s much better to implement the system out-of-the-box (OOTB). It results in fewer incidents and helps us ensure the processes our company are executing are the best of the market. We’re migrating to R2021x this year, so that migration will be easier if we stick with standard processes.”

In addition, Cobos says there are still many new platform functionalities that MTorres is anxious to roll out to its users.

“We know 3DEXPERIENCE has many more functionalities, and we still have work to do to make the most of the system…things like workflows and change management are all still in work for us. COVID has slowed the process, but we’re looking - at some point - to configure products in the system with variant management and to have all the document management functionality in play. These things will come in Phase 2 of our implementation.”

In the future, Cobos says, MTorres also has plans to integrate the platform with their electrical design application and its enterprise resource planning (ERP) system.

In the meantime, Galarregui says it also is very easy to configure the platform to particular tasks. “Some weeks ago, we needed to improve the way we mark preliminary drawings that we send to our suppliers. So we contacted our partner, ABGAM, and there was an easy solution to configure 3DEXPERIENCE, so it makes our life easier.”

Doing more with fewer resources

Cobos says, especially in challenging times, such as the COVID pandemic, solutions like 3DEXPERIENCE are critical to remaining productive and being able to do more with fewer resources. “

Saez agrees. “For MTorres, this project has been a first step. We must continue to work hard and continue to implement all of the new 3DEXPERIENCE platform solutions that we have discussed.”

“Dassault Systemes is one of our star partners. It’s a long-term strategy for us to keep implementing the 3DEXPERIENCE platform.”

The strategy has been validated by MTorres’ selection by Airbus as one of its early-adopter suppliers to work in its process digitalization program (Digital Design, Manufacturing & Services, DDMS), which has 3DEXPERIENCE at the center of its initiatives.

“Having 3DEXPERIENCE in place is a big advantage for MTorres,” Cobos adds. “Dassault Systèmes is one of our star partners. It’s a long-term strategy for us to keep implementing the 3DEXPERIENCE platform. We’re looking forward to upgrading to new versions of 3DEXPERIENCE to continue to take advantage of new functionalities and to integrate the platform with our ERP as the ‘heart’ of MTorres. In fact, we began our migration to R2021x in March 2021, demonstrating our continued commitment to Dassault Systèmes solutions.”

Focus on MTorres

MTorres develops engineering projects for the aeronautical and paper converting sectors on five continents. With its headquarters in Navarre, Spain and operations in Germany, the United Kingdom, the United States, Brazil, China, and beyond, MTorres serves more than 650 clients in 70 countries.

For more information: www.mtorres.es

Focus on ABGAM

ABGAM, belonging to the Segula Technologies group, is a consulting company specialized in the implementation, the development and the support of Dassault Systèmes solutions (CATIA®, DELMIA®, ENOVIA® and SIMULIA®) in Spain and Portugal. The company provides its technical experience through 12 delegations in Iberia, in major industrial sectors like automotive, aeronautics, capital goods, railway, energy and civil works.